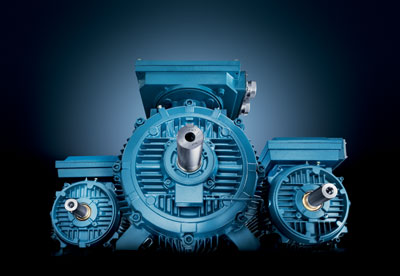

Nuevas normas para medir la eficiencia de los motores de forma más precisa

23 de abril de 2009

Comparándolos con otras máquinas, los motores eléctricos son bastante eficientes. Un motor de alta eficiencia de 90 kW convierte un 95% de la energía que utiliza en trabajo útil. Un motor de coche solo utiliza de forma eficiente un 40-45%. Pero el gran número de motores instalados implica que unos cambios pequeños en eficiencia, supongan una gran diferencia. El objetivo de la nueva norma es conseguir mayor consistencia en la forma de medida en todo el mundo.

Anteriormente, se han desarrollado diferentes normas de prueba para cumplir requisitos de aplicación, sin tener como objetivo prioritario la medida de la eficiencia del motor. Estas normas de medida daban una indicación de la eficiencia del motor, pero cuando se usaban para comparar valores de eficiencia, llevaban a ver motores con distinta capacidad de aprovechamiento energético e igualmente eficientes, dificultando al usuario la elección basada en buena información. “Damos la bienvenida a la nueva norma internacional IEC para prueba de motores eléctricos de baja tension y particularmente al hecho de que los valores de medida de eficiencia van a estar más armonizados en todo el mundo. Hemos esperado durante mucho tiempo a que se desarrollara este escenario”, señala Mikko Helinko, director de R&D de motores en ABB. ABB ya realizó todas la pruebas de acuerdo a la nueva norma en sus rangos de motores y publicó los nuevos valores de eficiencia durante 2008 y principios del 2009, tan pronto como se completaron las pruebas.

La eficiencia determina los costes de operación del motor

La eficiencia decide los coste de operación del motor y las emisiones de CO2. Un motor de alta eficiencia (Eff1) cuesta normalmente entre un 10 y 15% más que un motor de eficiencia estándar (Eff2). Sin embargo, esta diferencia de precio se amortiza rápidamente en ahorro energético. El coste de compra de un motor representa aproximadamente sólo el 1% del coste total de su ciclo de vida, siendo el consumo de energía la parte más grande de su coste.

Tres bandas de eficiencia

Con el respaldo de la Comisión Europea, los fabricantes que representaban el 80% de la producción en Europa de motores estándar acordaron en 1998 establecer tres bandas de eficiencia (Eff1, Eff2 y Eff3) para motores de inducción de 2 y 4 polos, de 1,1 a 90kW. Esta eficiencia se medía de acuerdo a una versión modificada de la norma de pruebas EN 60034-2 (1996).

El sistema europeo acertó en quitar del mercado los motores de eficiencia más baja, Eff3. Sin embargo, tuvo menos éxito en introducir la categoría de eficiencia más alta, Eff1. Desde el año 2000 a 2005, el mercado de motores Eff3 cayó de un 43 a 4%. Eff2 aumentó de 54 a 85%; pero Eff1 sólo consiguió un 9% de cuota de mercado en 2005, desde un 3% en el 2000.

Aunque solo estaba pensado para ser efectivo desde 1999 hasta finales del 2003, este esquema europeo se mantuvo. Representó un gran avance para su tiempo, pero hoy en día ya no es un indicador bueno de la eficiencia del motor y no se puede utilizar para distinguir en los tipos de motores más eficientes en la banda Eff1. Esta norma aplicada en Europa necesita ahora ser reemplazada y entrar dentro de la tendencia global.

Hoy, 10 países con una demanda de energía eléctrica mundial del 47% tienen en sus directivas marcados niveles de eficiencia mínimos en los motores. Se espera que se unan a este club en 2012, 14 nuevos paises. Entre ellos, los europeos que están siguiendo el esquema anterior. Esto cubrirá el 80% de la demanda de energía eléctrica mundial.

La eficiencia del motor se puede medir directa o indirectamente.

La medida directa implica comparar la entrada de energía eléctrica con la salida de potencia en el eje. A simple vista, éste parece el método más sencillo, pero la medida directa requiere de técnicas de medición extremadamente precisas y depende de la temperatura de la habitación- una temperatura más baja hará parecer al motor más eficiente. Con la medida indirecta, la potencia de salida se determina midiendo la potencia eléctrica de entrada y las pérdidas asociadas en el motor. En este caso, la potencia mecánica es la potencia eléctrica menos las perdidas.

La nueva norma, IEC 60034-2-1: 2007-09, permite varios métodos de medida:

• Medida directa como se utiliza en la norma IEE112-B de Norte América (medida del par)

• Medida con las pérdidas adicionales determinada por pruebas a cargas parciales (método indirecto)

• Medida con las pérdidas adicionales estimadas entre el 2,5 y 0,5% de la potencia de entrada a carga nominal, dependiendo del tamaño del motor (método indirecto)

• Cálculo matemático para las pérdidas adicionales

Bajo la nueva norma, los fabricantes pueden seleccionar cual de los métodos de medida utilizarán. En la documentación del motor se debe indicar que método de medida se ha utilizado. “ABB utiliza el método de determinación de las pérdidas adicionales por medida a cargas parciales, que estimamos puede dar el mejor reflejo del valor real de la eficiencia”, explica Helinko.

Norma anterior vs norma actual

| Norma anterior de medida de eficiencia EN/IEC 60034-2:1996 | Norma actual de medida de eficiencia IEC 60034-2-1: 2007-09 |

| Método directo | Método directo |

| Método indirecto: | Método indirecto: |

| • pérdidas adicionales se estiman como el 0,5% de la potencia de entrada a carga norminal. | • se determinan las pérdidas adicionales por medidas a cargas parciales |

| • se estiman las cargas adicionales como el 2,5 y 0,5% de la potencia de entrada a carga nominal | |

| • se establecen por cálculo matemático | |

| Pérdidas en los bobinados de rotor y estator determinadas a 95 °C. | Pérdidas en los bobinados de rotor y estator determinadas a 25 °C + incremento de temperatura real del motor |

Pérdidas del motor

Como el método anterior estimaba las pérdidas adicionales y en consecuencia las totales demasiado bajas, los nuevos valores de eficiencia calculados serán ligeramente inferiores. El nuevo valor de eficiencia no significa el diseño o el funcionamiento del motor haya cambiado, sólo que la eficiencia se mide ahora de forma mucho más precisa.

| Potencia de salida | Eficiencia según norma anterior EN/IEC 60034-2:1996 | Eficiencia según norma actual IEC 60034-2-1:2007-09 |

| Motor ABB 7,5 kW, 2-polos | 88,4% | 87,9% |

| Motor ABB 11 kW, 4-polos | 90,9% | 90,3% |

| Motor ABB 160 kW, 4-polos | 96% | 95,45 |

Nueva clasificación

La mayoría de los motores pequeños usados en las casas como lavadoras, etc., no están cubiertos porque se considera que están bajo otros esquemas que tratan de la eficiencia de la aplicación completa. Tampoco se aplica a los motores eléctricos para vehículos, que son a menudo hechos a medida.

El método de marcado actual (Eff1, Eff2 y Eff3) se reemplaza por una nueva clasificación IEC de motores según su eficiencia (IEC 60034-30). Los fabricantes tienen que volver a probar sus motores. Cada tipo debe ser probado individualmente, por lo que esto conlleva un gran esfuerzo.

IEC 60034-30 introduce una nueva clasificación, (IE1, IE2 y IE3), que abarca a muchos más tipos de motores que anteriormente:

| Parámetro | Nuevo estándar de clasificación : IEC 60034-30 – CDV : 2007-08-31 | ||

| Tensión y frecuencia nominal | UN hasta 1000 V - FN : 50 y 60 HZ Connexión directa 'online' | ||

| Gama de potencias | 0,75 a 370 kW | ||

| Número de polos | 2, 4, 6 | ||

| Validez para motores | Incluye: motores estándar, motores para atmósferas explosivas (Ex), motorreductores y motores freno | ||

| Ciclo de trabajo | S1, S3 con tiempo de operación ≥ 80% |