Fortatech Accelerates the development with Proto Labs

Thanks to the flexible and innovative services of

With headquarters in St. Gallen, northwest of Switzerland, created Fortatech (member of Brugg Group) in 1878, year in that the company initiated his career like manufacturer of ropes. In the actuality, Fortatech employs to some 2.000 people all over the world supplying systems of wiring to customers of sectors like the automotive sector, the manufacture of machinery, the aerospace sector, the medical sector and the scientific sector. Of course, situate by in front of the competition means to satisfy the most demanding tendencies of the market, and one of the most important in the last years is the remarkable increase of the demand of articles with terms of short delivery.

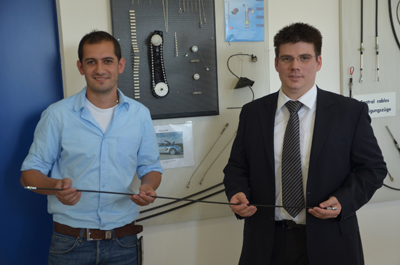

“Some of our customers demand now personalised pieces in a term of alone 14 days”, explains Thomas Englert, general director of Fortatech. “Nevertheless, with the help of Proto Labs, can offer them the solution”.

With this aim, Englert pretends to plant to Fortatech as much more that a simple manufacturer, although it produces until 200.000 units of determinate cables.

“Our strong point is the capacity to offer to the customer develop and support, taking advantage of our experience to design the correct solution, that, of course, can manufacture also in big quantities”, comments. "Our customers demand terms of short delivery and an enormous flexibility, but without renouncing in way any to the quality.

Therefore we need providers that are able to offer this degree of excellence", explains Englert.

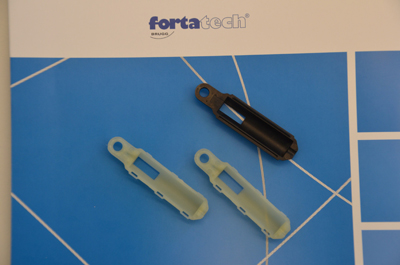

A recent example was the development of the carcasa of a special spring to divert a wire. The spring had to be surrounded of a pair of half carcasas that allowed to the mechanism glide to the ceiling of a descapotable of a known mark of sportive trucks situated in Zuffenhausen, Germany. The customer demanded the delivery of 100 pieces in little time.

“Thought immediately in Proto Labs”, remembers Zarko Andjelkovic, director of project of the department of engineering of Fortatech. “It is necessary to stand out that we had to manufacture the pieces with final materials. We did not have the option to create fast prototypes with materials of replacement, since these would not bear the conditions of real work. Fortunately, the degree of cooperation offered by Proto Labs was excellent”.

The original idea of Fortatech was to connect the two halves contenedoras by means of a clip, a design that did reality in few days thanks to the service of moldeo by fast injection Protomold of Proto Labs.

“The answer of Proto Labs was excellent. However, during the setting darse that this type of connection did not fulfil the requirements”, affirms Andjelkovic. “In very little time had a second design, manufactured again with Protomold, that joined by ultrasonic welding. This time, our rigorous proofs of laboratory resulted satisfactory. The customer remained impressesed when we did the delivery in a record time, with the documentation of the results of the proofs and a calendar of delivery of the pieces of production”.

Englert Shares his enthusiasm: “For us, Proto Labs supposed an authentic success from the first moment”, comments. “It provided us a free analysis that helped us to obtain the design of a piece headed to the production in the necessary plastic. In few days, receive pieces of big precision. Economically, we come off well also. The cost something upper of the pieces results insignificant in comparison with the cost of a mould for complete production”.

The advantages to use the process of Protomold went back to go out to the light in another article of Fortatech: a spherical support for the extreme of a wire that measured only some millimetres of diameter.

“Also is for the ceiling of a descapotable”, explains Andjelkovic. “Alas, I can not give more details because the model will take still two years in going out to the market. Nevertheless, during this phase of development Protomold allowed us experience different plastic solutions. This piece is used to to manufacture with metal, by what the possibility to manufacture it with a cheap plastic resulted thrilling. Besides, since the wire goes by the ceiling and the installation remains exposed to the inclemencias meteorological, it is necessary to avoid possible problems of corrosion”.

Fortatech Opts in this case by Firstcut, the service of mechanised fast CNC of Proto Labs. For example, in a project of exploration of different materials for the component.

“Treated of the adecuación of the stainless steel like basic material in place of the alloy of fine zinc”, explains Englert.”The piece has form of L, measures only some millimetres and is partially hollow. The material of stainless steel forms the extreme of a wire and carries a moldeo external of plastic. Because of the adjusted term of delivery, never would find a workshop of CNC able to adjust his calendar to our demands of production. However, Proto Labs provided us these diminutas pieces of stainless steel in only some days so that we could begin the proofs. At the end it resulted that, although the connection was resistant to the corrosion, offered a less powerful traction that the variant of fine zinc. The use of Firstcut offered us a fast and reliable answer. This type of results improves our reputation and satisfies even more to our customers".

In definite, the exclusive technologies offered by Proto Labs offer decisive advantages in the process of development of Fortatech, with the consequent profit for the final user.

“Are very satisfied to be able to offer a fast answer to the demands of our customers thanks to the services of Protomold and Firstcut”, concludes Englert. “Proto Labs Has turned into a reliable partner, that provides speed and agility to Fortatech”.