Get the most out of the chip

September 16, 2011

In a recent project carried out by Ehaff, the customer mechanised/mechanized in 4 centres/centers of mechanised/mechanized two types of different materials, bronze and steel (indistinctly), whose shaving generated collected in a container to the exit of the machine.

The challenge

The challenge required to automatically carry all 4 machines chip until a specific point of the ship, in which the bronze of the steel should be separated for later deposit each material in a different container.

The solution

The proposed solution required the pumping of chip each machine using a pumping until a filter station laminar, taking advantage of taladrina cooling element for this vehicle. In a first step, the filter separates the taladrina chip. Then filter fine particles returning completely clean to each of the winches. The filter is responsible for automatically constant maintenance of the concentration of the liquid, strange oils extraction (hydraulics, guides, etc.) that can be found on the surface of the taladrina and keep the taladrina on the move (although there is no production) avoiding the creation of micro-organisms.

Acero-bronce chip separated in the filter becomes a centrifuge machine to extract most of the emulsion, leaving her with a maximum of 1.5% humidity. Then becomes a magnetic separator of double effect by a vibrant, which gets split between 80-90% of the bronze of the steel swarf.

Results

The results were as follows:

- Chip of pure and dry bronze that the client can return to merge or sell getting the maximum benefit.

- Chip steel dry and therefore transportable, that the client can sell avoiding any penalty in waste management

- Longer life of the emulsion, with consequent savings on the purchase and management of the exhausted taladrina.

- Elimination of loss of staff in time:

- the transport of containers at the exit of the lathes

- the mixture of manual taladrina, making it automatically filter

- cleaning of the working environment

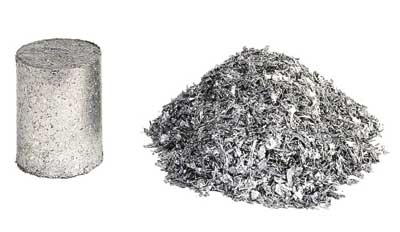

Closing the circle (crushed and chip briquetado)

Other two very interesting solutions in the management of chips are crushing and chip briquetado.

The process of grinding is very useful when you want to reduce the space occupied by a bulky chip or when you want to carry the chips by pumping or centrifuging her. In both cases, the size of the chip must be reduced.

The briquetado for its part, can be considered the last process of chips which we obtain briquettes or high-density ingots that optimize the transport of the material to be compacted and low humidity. Briquettes are appreciated by the smelter for its quality.