Wittmann Battenfeld launches a new model of 800 tons

MacroPower, the new model of large injection machines

The manufacture of large machines is a great tradition in Wittmann Battenfeld. Since the founding of Battenfeld Spritzgießtechnik in 1948, large machines have been a point of interest in the development of products. Battenfeld was named as pioneer in the branch and in a short time gained the leadership in the market. In 1991, Battenfeld released one of the machines of injection molding of greater capacity in the global industry, with 8,000 tons of clamping force. The concentration of products in the facilities of Kottingbrunn brought with it a change in supply to machines with rank of clamping force of 5 tonnes to a maximum of 650 tons. With the new series of MacroPower, Wittmann Battenfeld has extended their range to include models of 800 to 1,000 tons, thus acquiring the successful return to the manufacture of large machines.

In addition to the EcoPower and MicroPower machine, the MacroPower represents the third instalment of the range PowerSeries machines. The MacroPower this causing a stir in the market of large plastic injection machines with its outstanding technology thanks to many years of experience of Wittmann Battenfeld.

The PowerSeries demonstrates once again the strength of the company in innovations and his philosophy of maximum benefit of its customers.

Compact, fast, precise, clean

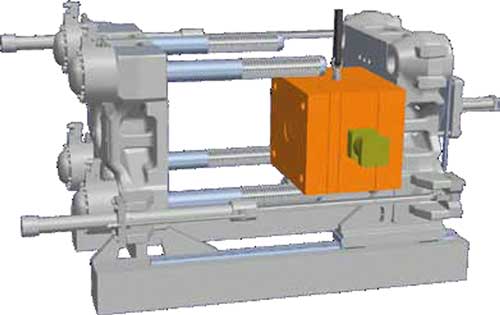

The MacroPower is distinguished by its extremely compact design, high speed, high precision and cleanliness.

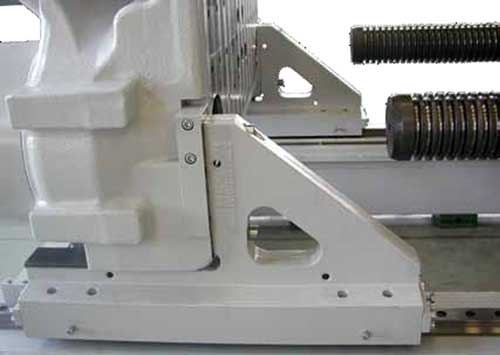

A feature unique in its category, are its small size. The solidity of the MacroPower, highly appreciated by the users, is the result of combining the new pressure of double plate system with the already known compact unit series Wittmann Battenfeld HM.

The optional integration of robot Wittmann on the machine reduces the space required as well as energy savings. The MacroPower is equipped with an innovative patented locking system, which allows very short blocking times. This combined with its fast movements makes the machine extremely fast. This machine dual-platter is extremely clean, thanks to its system of Rails for the mobile plate, which allows you to remove the tray from oil to lubricate the moving parts. The mobile plate linear guides are the key to accuracy, because that ensures that the plates work in parallel throughout procedure. Thanks to the dynamic friction, the protection system is extremely sensitive and the smooth working of their guides contributes to energy saving.

Easy insertion of the mold

A special feature of this new generation of machines is the ease with which the molds are inserted from the rear of the machine. A longest passing through the security protection on the back, combined with columns especially short, thanks to the blockade that has been integrated into the mobile plate, allow the inclusion of large moulds, in most cases, without the need of a device for extraction of the column. This not only facilitates the inclusion of molds if not which also reduces costs by not having to extract the columns and low ceilings are no longer a problem. The column extraction device patented by Wittmann Battenfeld is available as an optional attachment, it pulls the column with just a button which also provides enough space for large moulds.

Intelligent drive concept

The MacroPower three engines with electronic adjustment of pump-driven, modular concept implemented in three phases with parallel function, allowing to reduce cycle times. Also available is a cruise control servo drives of pump constant allowing energy savings as well as the reduction of noise, which is already of if low due to the insulating pump compartment.

One machine, many options for maximum benefit, the MacroPower offers pre-configured and modular design. A variety of options are available depending on individual requirements.

The system of the machine consists of a basic platform which can be supplemented with various packages according to the specific needs, such as applications of multi-componentes technology.

Unilog B6: 1 control system

The new MacroPower at the K 2010 fair

MacroPower with 800 tonnes of clamping force, presented this year for the first time in the days of competitiveness of the Group Wittmann, was greeted with enthusiasm by visitors. From October 27 to November 3, the model most recent of the injection machine, now expanded its capacity to 1,000 tonnes, will be exhibited for the first time at the K 2010 in Düsseldorf.