Increasing demand for solid transport systems

Through its Division of transportation of solids, Coscollola offers complete solutions, parts thereof, both basic and detail parts, asistencia… engineering He has to do this with a new engineer, Manager and coordinator of the same. "Our 'core business' - declare for plastics universal / Interempresas - is the engineering and development of solutions for the handling of liquids and solids (powder and pellets)." He is solutions as they can include vertical storage, pneumatic transport, systems of dosing, homogeneity of materials, despolvorización systems or processes in continuous and batch.

Pneumatic transport

Coscollola develops solution for pneumatic transport that best fits the type of product for the customer, to reduce transport times and energy consumption. Choosing the type of transport depends on the químico-físicas characteristics of the product (grain, sensitive to abrasion,...), the disposition and characteristics of the plant (distances transport) and the costs of investment.

When it comes to materials difficult to wear and tear are used to transport in dilute phase, a valid system for short and long tours. In these cases, transport speed is 15 - 35 m/s and emphasizes the high flexibility in the number of lines and low investment costs. Transport in dilute phase can be drive, aspiration or a mixed system of impulsión-aspiración.

Sometimes working with sensitive, and abrasive products for which Coscollola offers transport in dense phase, which can reach speeds of 2 - 12 m/s and is characterized by low consumption transport fluid and limited wear and tear of the pipe.

Silos

Their design of a system of transport supply Coscollola adds design of silos with different volumetric capacity (geometry and form). The silos are designed according to the calculation regulations and with the possibility of ATEX certification and include static homogenization systems: multi-barrel, central tube, cone with multiple sectors.

Manufacture unibody the same facilitates transport and field installation. They can be made in stainless steel, aluminum and painted carbon steel and incorporate a system of weighing, thermal insulation, cleaning and drying system. It offers the possibility of storing different products in the same silo and incorporate a self-supporting skirt until the soil.

In addition to special silos (in foil, fiberglass, hopper silos), Coscollola leverages the know-how of its represented to offer groups of feeding material to the extruders, compactors, universal fast mixers, silos for mixing and diverse special solutions.

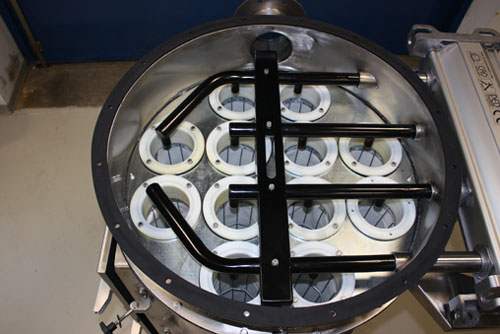

They also come into play the centralized and individual transport systems that work by vacuum for Pellet and powder as the of Motan, filters (to separate the airflow product), the fast extraction systems that are designed especially for products which do not flow freely and rotary valves, a component of great importance in the pneumatic transport of solids. Coscollola offers all these integrated systems on lines designs, as well as other many teams that can become necessary in a system of transportation, such as fillers, systems for sacks and 'big bags', systems of mechanical transport, drying and deshumidificado and other auxiliary devices. In addition, it develops internally control system, adapting to the demands of the client with the ease of use and efficiency objectives.