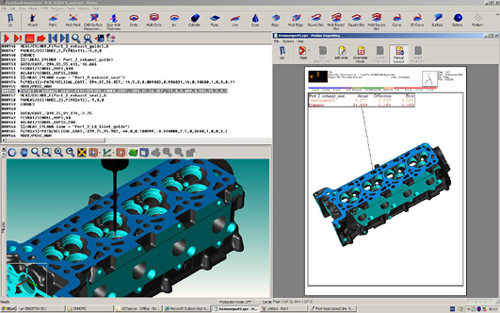

The new Modus for Renishaw MMC software includes 5-axis measurement

Renishaw has presented its new software application for MMC Modus, which provides a solution to 'retrofit' complete installed machines, with distribution and technical service of Renishaw customers of MMC. Fully compatible with the full range of sensors, including the award-winning Revo, Modus provides a powerful platform for 5-axis measurement. Its main functions include: programming without connection to CAD with full simulation of movement and collision detection, including paths on five axes; support original DMIS; approved mathematical algorithms; generation of complete reports of text and graphics; and flexible results data. The universal control UCC2 for Renishaw MMC is managed through the I ++ SMD interface.

The implementation Modus is designed on the prestigious software for MMC Metris Camio. In a recent agreement with Metris BV, Renishaw has acquired a license of the source code for Camio. Renishaw has also hired a team of engineers from Metris, which will be responsible for the future development of the Modus software.

"Having our own software significantly improves our offer for equipment already installed, complementing our current strategy of the Protocol interfaces I ++ DME with a system of purchase"all-in"says Ben Taylor, director Executive Deputy of Renishaw." Moreover, "The new team of engineers and the recent investments in engineering of software in the United Kingdom and the India, now have a package of metrology of first class and the means to develop it." Our strategy is to improve Modus to be informed of upcoming solutions, including the new sensors for the Revo platform. "In this way, users of MODUS have always the guarantee that will be the first to benefit from technological innovations in metrology."

Easy to program with complete simulations

Modus includes a configurable UI that allows to develop original DMIS programs offline. Programs can be created directly in CAD with verification of the trajectory of the probe on the screen. The MMC environment, can define the tooling of fixation and the location of the workpiece on the machine, which allows a complete simulation of movement and collision detection, including trajectories with 5 axes. Thus, it reduces the time of inactivida of the MMC, as programs are installed on the machine ready to run, with minimal preparation time.

Modus includes a wide range of programming, measurement and reporting functions, however, given that most users just use one part of the user interface, both design as content can modify tailored to the requirements of the user. Toolbars are completely configurable, so you can display only the necessary buttons and place them exactly where preferred. User in graphical format instructions, sensitive to the context, are scheduled in several ways: tickets of the keyboard, 'learning' through the joystick control or directly from the CAD model data.

Programs editor supports real original DMIS. It includes commands of high level, such as Declaration of variables, logic programming, macros, intrinsic functions and messages for the operator by means of dialog boxes that the user can define. It also has automatic error recovery during the implementation of the programme.

Wide compatibility with CAD

In addition to the neutral formats of IGES, STEP, Parasolid and VDAFS, Modus provides integration of high quality with CATIA (V4 and V5), Siemens NX (formerly Unigraphics), Pro/E, Solidworks CAD/CAM solutions. The software also includes repair and simplifying technology to optimize the CAD models. Users can select parts and nominal dimensions of one or several CAD models imported geometries, and compare the data with nominal CAD. In addition, consult the manufacture of the product (PMI) from CATIA V5, Pro/E and models NX, using the dimensional information and information accessible integrated tolerance using the module of solution of planning Modus. The labels of the piece are maintained during the workflow of CAD to the inspection report.

Demonstrated ability of measurement and analysis

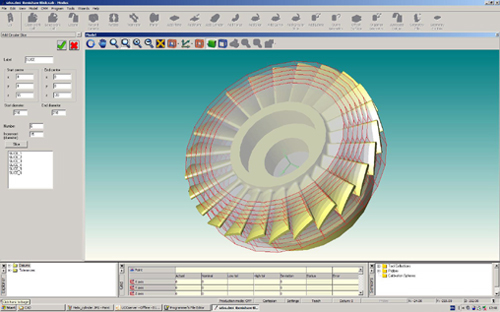

Modus completely uses the extensive range of measurement of parts and construction routines of camio. the various parts including circles, lines, planes, points, cones, curves and surfaces, as well as on parts of little thickness measurement. It is also possible to construct pieces with intersections and projections. techniques of location and orientation of the pieces range from 3-2-1 simple methods to more complex structures with free and iterative alignments. adjustment of pieces approved algorithms include square minimum, minimum circumscribed, maximum inscribed and max/min it is possible to filter the data scanned into geometric pieces. the piece is an intrinsic part of the contemporary techniques of inspection, therefore modus includes generation based on rules of measurement for the exploration of contact routes continuous 3 and 5 axes, and generates the data necessary to fully analyze complex pieces of work.

Flexible reports

The capacity of reporting of Modus is very broad and includes the traditional text of MMC reports with many formatting options defined by the user. Generating graphical reports can display the results with the CAD model, including the Whisker graphics or layout of 3D shapes of different pieces.

Created on a solid base of industry standards, Modus maximizes compatibility with a number of programs and user reports. Results data can be generated for applications from other manufacturers in a number of formats, like Excel (CSV), text ASCII, DMIS, XML for Internet or directly in Microsoft SQL Server databases. The user can also customize the output file with parameters as the serial number of the piece.

Trend data can be displayed on a series of pieces in various graphs SPC (statistical process Control). In addition, prominent Q-DAS SPC package users have access to all the options using a simple customizable user interface, from which can run studies 1 and 2.

Standards-based and prepared for the future

Installed Renishaw to MMC solutions have been created on industry standards and recognized technologies, to increase the flexibility of use. Modus is connected to the universal control UCC2 for Renishaw MMC using the I ++ DME Protocol, which provides a common language for metrology commands. In this way, users of UCC2 are free to choose other metrology applications compatible with the Protocol I ++ DME, without being subject to a unique solution of a brand.

Modus is an investment for the future which guarantees access to the most current sensors and the latest technological advances of Renishaw. It includes sensors for the head of measurement of 5-axis Revo, the first of which will allow the automatic measurement of area (available at the end of 2009) finish.