Krauss Maffei reinvents the production combining processes of transformation of plastics

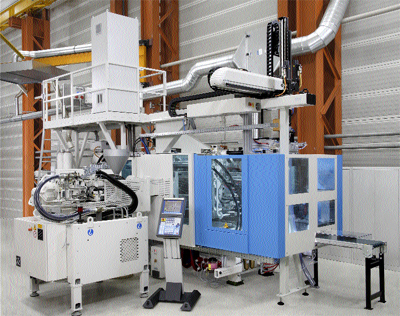

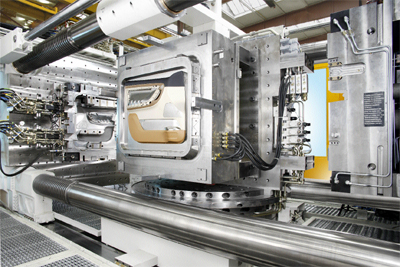

SkinForm is the combination of PUR (polyurethane) processing technique of injection molding. This is not new, but now you can also apply to higher ranks of clamping force. Thus reducing the costs of manufacturing of the components of large surfaces and prepared for the Assembly. SkinForm allows a coating of a thermoplastic substrate with polyurethane in the thicknesses and various colors, without any transformation of the team. Thus was shown at the K2007, in collaboration with the company Cadence Innovation of Liberec/Czech Republic, the manufacture of a component of the carrier of cars with a reversible plates 2300 KM-12000 MX SpinForm machine. In this way, Krauss Maffei featured installation of moulding largest injection which has never exhibited in the K: the production cell whole (including automation) is 21 meters and weighs 300 tons.

With the newly designed reversible plates machine is manufactured during the first round a complex thermoplastic plastic support. Later, the machine refines the plastic support during a second round with surfaces of polyurethane in different colors. Several heads mixers, coupled staring into the tool provide the PUR (polyurethane). A finished component is thus formed in each cycle. Different areas of the PUR (polyurethane) in different colors can be made at the same time.

The Union of several technologies

A new concept of Krauss Maffei methods reaches cycle times significantly reduced in the manufacture of components with damping of oscillations that it unites the extrusion, injection molding and the technique of reaction in a single element of manufacturing. In this way Krauss Maffei three technologies in a single concept of manufacturing. To this end Krauss Maffei has developed the fully automated manufacture of a component 2 K-oriented practice with damping of oscillations integrated, comparable with a torque support.

The support and the sleeve for the absorption of force are made from PA66-GF35. Then joins the CAP and support with a cushion soft component. As the buffer layer material applies a new TPU-X (thermoplastic polyurethane), that is after the moulding and during the cooling grid. As agent reticulador prepolímero is introduced in liquid form to the molten mass of TPU. With this complex task meets the compound of Krauss Maffei, which links the extrusion and molding by injection.

ClassiX: individual accuracy at a low price

The new ClassiX series offers a molding technique effective injection with an attractive ratio. ClassiX series machines can be configured individually with the catalog of standard options of series CX and are offered especially for applications that do not require any special version. Through the combination with the new LRX series linear robots, increasing productivity of machines. ClassiX series is available in a range of clamping force of 350 up to 1,300 kN and opting for proven technique: exactly 15 years ago, the Krauss Maffei company introduced the first machine of molding injection with a technique of closure of two plates on the occasion of the f112.

ClassiX series has the same flexibility that the CX series and is thus the ideal basis for economic production of molding by injection with the higher requirements. The proven technique of closure of two dishes reduces the length of the unit's closure. In this way is possible to maximize the available production surface. The unit of self-supporting closure is easily accessible and allows a simple evacuation of parts of injection.

ClassiX series offers also suitable injection group and a version of ideal spindle for each production function. With a great multitude of possibilities of combination of closing and injection units, machines can be adapted to the special requirements of each case. Thanks to the concept of modular drive for energy savings, the machines are especially productive. For each point of service provides the necessary amount of oil with the corresponding pressure. This allows a high capacity of production with reduced costs.

ClassiX series is equipped with the control system 5 MC, an easy to use-oriented. The user interface provides a process simple and clear, without overloading the operator with the information. Comprehensive monitoring and evaluation functions allow a rapid analysis of the process.