Relation between the measure of position and the finishing of the pieces in the machines of numerical control

J.L. Of the Crag, T. Morlanes And J.And. Oti Of

One of the problems that more interest wake up in the field of the mechanised of pieces obtained with machines controlled with numerical control is the one of the quality of the same regarding his precision and finishing refers . They are many the variables involved in the quality of the mechanised: bancadas, material, numerical control, motors, regulators, algorithms, dynamics of the system, environingingmental stability (vibrations, humidity, temperature), quality of the systems of catchment (closing of the bow), etc. In this presentation go to centre us in this last variable being the aim of the present work visualise how the election of one or another system of catchment affects directly to the finishing of the pieces mechanised. In particular it pretends relate the quality and resolution of the proportionate signals by the systems of catchment with the finishing of the pieces and see how the small imperfections that can present said signals because of the setting of the system of catchment or the quality of the same affect directly to the finishing of the pieces.

The distribution of the work is the following: Presentation of a simple theoretical model for the visualisation of the proportionate signals by a system of catchment, theoretical analysis of the relation between the quality of the signals and the finishing of the pieces mechanised, presentation of some experimental results, conclusions and appearances of improvement.

Development

A codificador is an able device to determine the relative position between two parts, a mobile and another fixed. For this generate electrical signals that they are sent to the zone of control of the system for his treatment. We say that a codificador of position is optical when said electrical signals are generated from optical considerations. To the equal that any another device of measure, has two fundamental characteristics: resolution and precision.

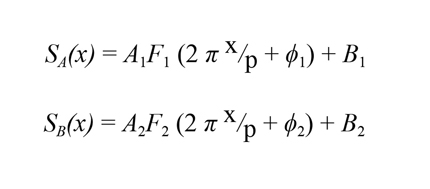

Resolution: Corresponds to the minimum increase of the physical magnitude that it is able to resolve the system of measure.Precision : it Corresponds to the error that can commit when measuring with the system of measure. The coding optical use in processes where requires of a high degree of precision and resolution, as they are the processes of mechanised of high quality. In principle, the basic resolutions that obtain with this type of coding move in the surroundings of the micras, although it is possible interpolar the signals, being able to reach resolutions of nanómetros. Regarding the precision of the same, resaltar that this depends on several factors as they are the mechanical system, the quality of the recorded, the adjust of the signals, etc. Mathematically the signals of a codificador of position can represent eat:

Where x is the position, p is the period of the rule, To1 and To2 are the amplitudes, B1 and B2 are the levels of descentramiento (offset), φ1 and φ2 they are the desfases between the signals and, finally, F1 and F2 are the functions that describe the form of the signals. Ideally these signals would have to fulfil the following conditions:

- The amplitudes are equal To1 = To2 = To

- The descentramientos are invalid B1 = B2 = 0

- The desfase between signals is of a chamber of the period φ1- φ2 = π/2

- The signals are senoidales F1 = F2 = sen

If we represent the evolution of these signals, one in front of another, obtains the designated diagram of Lissajous that, in the ideal case corresponds with a perfect circle centred in the origin. Said diagram repeats each period p of the rule. The codificador does use of said diagram to realizar estimates of the height position from the variations that presents the existent phase between both signals with the trip.

Factor of interpolation and finishing of pieces

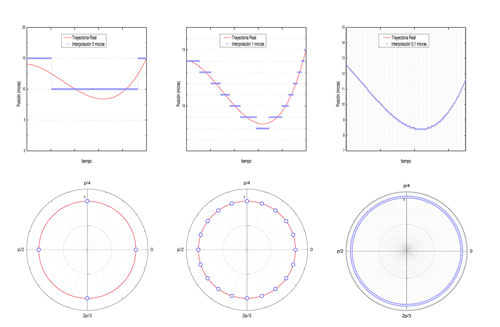

Designate factor of interpolation to the number of sectors-divisions that the codificador uses for discretizar the diagram of Lissajous. In this sense, say that said factor is closely related with the finishing of the pieces mechanised because what elder was this, with greater detail and accuracy will reproduce the continuous circle theorist and thus more exact and detailed will be able to be the positioned of the tool. Gráficamente Can visualise this fact in the following mock example. The Figure 1 sample a path to be followed (red line) and the positioning of the proportionate tool by a codificador optical of 20 micras in passing when it considers an interpolation of 5, 1 and 0,1 mm. Under similar conditions of work, what elder was the factor of interporlación, better will adjust the tool to the real and better path will be, therefore, the finishing of the piece.

Are to continuation two real examples.

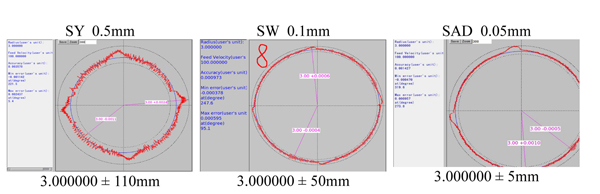

Example 1: Realisation of a circle 3 m of radius keeping the same conditions of work except the codificador optical. The Figure 2 sample the circle obtained for 3 rules Fagor —model S— with resolutions of 0,5, 0,1 and 0,05 mm. In all the cases obtains the circle of the dimensions wished, although the finishing of the piece results finer what greater is the degree of interpolation of the codificador.

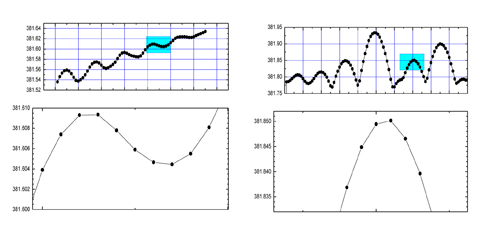

Example 2: The Figure 3 shows real data of paths collected by a machine that uses a rule Fagor SAD (interpolation of 50 nm). The high level of interpolation allows the follow-up of paths very detailed and fine.

Appears 3: Example and detail of paths that can achieve with coding with a degree of interpolation of 50 nm —scale axis And, in mm—.

Error subdivisional and finishing of pieces

A codificador optical is a device where see involved different technologies or disciplines: Optics, Electronic, Mechanical, Software. In his process of manufacture, adjust and setting can give situations of inhomogeneidades optical, of unfit electronic because of the tolerances of the electronic components used, mechanical tolerances of setting, etc. Like result of all the these possible incidences, the proportionate signals by the codificador optical will be able to differ slightly of the ideal signals in several senses: the signals can that they are not perfectly sinusoidal, will be able to appear descentramientos (offsets), desfases, changes of amplitude, etc. When this occurs the diagram of Lissajous that observes separates of the perfect “circle”. If it applies then the algorithm of the arch-tangente point ready, can calculate and visualise the difference between the height estimated by our Lissajous and the height estimated by the Lissajous ideal. Said difference is what knows like ‘error subdivisional' and is inherent to all real setting.

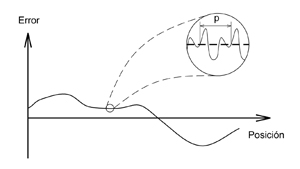

This error presents a periodic character —period p of the rule— and affects among others a lot of appearances to the general dynamics of the system and therefore to the finishing of the pieces. To continuation are some mock and experimental examples.

Consider situations in the which the adjust of the signals has not been perfect and the diagram of Lissajous does not correspond with a perfect circle. This can simulate it entering light changes in the parameters of the equations showed previously.

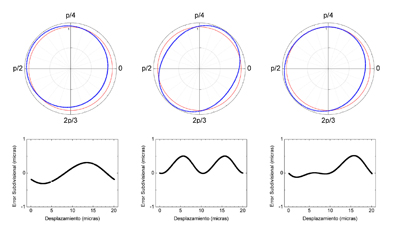

The Figure 4 sample three examples simulated so much of the Lissajous as of the error subdivisional that obtains .

Is important resaltar that this error superimposes to the graphic of proportionate precision by the manufacturers (see Figure 5).

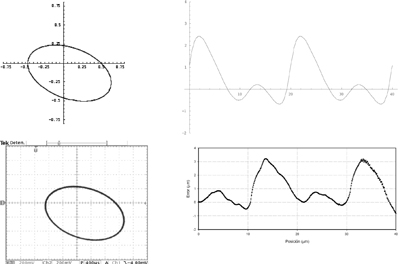

Have measured and ascertained the existence of said error. The results show in the Figure 6. It considers a descentramiento of the diagram of the Lissajous and calculates the error subdivisional that corresponds him; it takes then a codificador optical real and unfits until obtaining a Lissajous similar to the mock. It measures then the graphic of precision in some very small surroundings ±p obtaining like this the error subdivisional real. As it can see, the agreement simulation-experiment is acceptable and clarificador.

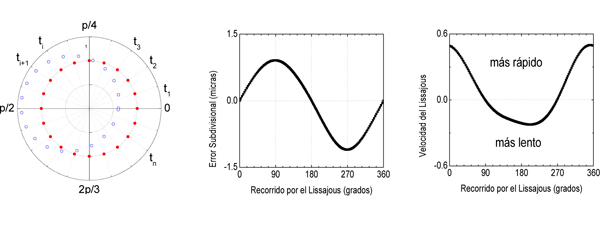

Consider a situation like which shows in the Figure 7. We suppose that the system displaces to constant speed and that, equally, exists a demand of height each true intervals of time you equidistant between yes, for example, each 125 micro-second. Under these conditions of work, our codificador, like consequence of the error subdivisional will provide heights more or less advanced (blue points) regarding the ideal height (red points). In other words it is as if the codificador advances or delayed regarding the ideal situation or like this did not visit the Lissajous to constant speed but it was more or less fast along a period. This effect can see gráficamente in the own Lissajous. The first stretch of 5 first micras (first quadrant) is route more quickly that the seconds and third stretches (second and fourth quadrant). If we represent the derivative of error subdivisional can see this effect.

Although each period p, the codificador bad adjusted gives a complete turn to the Lissajous and thus it does not lose contaje, is true that the Lissajous is not visited to constant speed but in some zones goes faster that in others. This fact affects directly to the dynamics of the system, since in front of constant demands of speed (62,5 microseconds) and position (125 microseconds) the system recognises ‘advances and delays' unwanted that tends to compensate affecting to the general dynamics of the system.

Summary and areas of improvement

The coding optical are the devices preferably employees, by the manufacturers of machine-tool, like element for the re-feeding of the position. The resolution and precision with which determines said position affects to the finishing of the pieces. In this work have centred us in two characteristics of the coding: the factor of interpolation and the error subdivisional. We have seen like the first affects to the good reproducibility of the real paths whereas the second can affect directly to the dynamics of the system. The development of new optical technicians of interaction between mobile parts, the treatment of the optical signals of conjoint way —only field—, the use of photodiodes structured and of electronic components of high range can help to minimise the effects of descompensación and unfit of the electrical signals and reduce like this the error subdivisional. Still when east is present, is possible to minimise it from treatments software of the signals and of the implementation of complex algorithms.