RTM In the sector of the automotive sector

Anabel Crespo Soler, department of Composites in

The replacement of pieces manufactured with conventional materials by pieces manufactured with compound materials contributes to the reduction of the weight of the vehicle, to a greater efficiency in the consumption of the fuel and to an improvement in the relation between power and weight of the vehicle what translates in a greater performance of the same. Historically, the use of materials composed in the sector of the automotive sector has seen limited had to, fundamentally, to the times of cycle (capacities of production). However, the new rules that affect directly to the broadcasts of CO2 are promoting the use of materials composed in this sector.

In the European Union (EU), the road transport contributes roughly a fifth part of the total broadcasts of carbon dioxide (CO2), main causante of the effect invernadero. The transport is the only important sector in the EU, where the broadcasts of gases of effect invernadero follow increasing; almost 23% between 1990 and 2010. The European Commission has set up, following the strategy that adopted in 2007, a global juridical frame to reduce the broadcasts of CO2 of the new light vehicles like part of the efforts to guarantee that it fulfils with his aims of reduction of broadcasts of gases of effect invernadero under the Protocol of Kioto and further. The legislation establishes objective vinculantes of broadcasts for the trucks and vans. For the trucks, the manufacturers are forced to guarantee that his park of new vehicles does not issue more than an average of 130 grams of CO2 by kilometre (g CO2/km) in 2015 and this figure has to diminish to 95 g CO2/km in 2020. For vans the compulsory aim is of 175 g of CO2/km for 2017 and 147 g of CO2/km for the year 2020 1.

One of the most effective strategies when the manufacturers of vehicles confront to the challenge to reduce the broadcasts of CO2 is the reduction of the weight of the vehicle where the compound materials play a fundamental paper. The moldeo by transfer of resin (RTM) is a process for the manufacture of composites that has attained a notable importance inside this sector since it allows the obtaining of pieces with a finished ‘class To'. In this process, the reinforcement of fibres plants in the interior of a mould. To continuation, the mould closes and injects the resin. After the cured, the piece desmoldea and prepares for the following phases of painted. This system of production also allows the application of a gel coat that will constitute the expensive surface sight of the piece deleting the back phases of painted. The moulds employed in this process can be of distinct types, from moulds of aluminium, steel or nickel of greater cost until moulds of resin more economic.

Notices:

1 ‘European Comission' Climate. European Comission, Web. 12 Dec 2013.

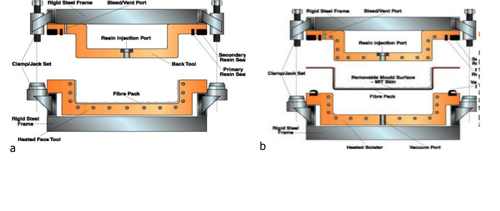

The process of RTM has gone evolving along the years with the aim to improve the quality of the pieces and the times of conventional cycle (between 15-85 minutes 2). The balance between the type of resin of injection, the design of the mould and the process has been, and keeps on being, fundamental to attain this aim. In 1997, JHM Technologies, Inc. and Plastech in the United Kingdom developed what knows like Mould of RTM of ‘leathers' interchangeable (MIT). This method incorporates, in a same mould, multiple identical faces (leathers) of low cost. Whereas in the leather situated in the mould, injects and polimeriza the resin, another leather can be used in the phase of application of gel coat and, to continuation, in the placing of the reinforcement of fibre. In this way, the systems of interchangeable leathers contribute to the decrease in the time of production of a piece.

At present, the main agents involved in the process of production by means of RTM (producers of raw materials, equipment, manufacturers of vehicle…) are working in distinct systems with the end to achieve a total decrease of the times of cycle. An example find it in the development that are carrying out Momentive Specialty Chemicals' (Columbus, Ohio) together with Cannon (Boromeo, Italy) and KraussMaffei (Munich/Eppigen, Germany) for BMW. In east, have obtained systems of resins epoxi of five minutes of cured (is working in the obtaining of cycles of cured of two minutes), that combined with equipment of high pressesure of injection (until 200 bars of pressesure with ratios of injection of 200 g/s) have attained a decrease of the times of cycle. On the other hand, Huntsman Polyurethanes (Everberg, Belgium) together with Frimo (Lotte, Germany), company specialist in the production of pieces of RTM, has developed resins of polyurethane of cured fast that used with reinforcements of fibre constitute an alternative in the market of the compound materials. Another division of Huntsman, Huntsman Advance Materials, works in what they have designated like Fast RTM, with pressesures of greater injection of 15 bars. In this last case, have achieved time of cycle between 5,5 and 13 minutes, including the times of placing of the preforma in the mould, injection, cured and desmoldeo. Also they are realizar efforts by part of manufacturers of fibres that are developing prepegs of cured fast and manufacturers of equipment (presses, equipment of injection, robots) that improve his equipment to attain the common aim of reduction of the times of cycle 3.

Inside this frame, Aimplas works, together with other 12 European partners, in the European project Ecogel Times. The main aim of this project is the development of an ecological system of RTM of high productivity. For this, goes to work fundamentally in two appearances;

- The formulation and manufacture of a gel coat in dust of cured fast that will diminish the broadcast of volatile organic compounds in the plant of production and

- the design and the construction of moulds with interchangeable systems of ‘leathers' reinforced with fibres of carbon and calefactados electrically.

Notes:

2 Klaus, Ritter. ‘RTM advances facilitate mass production in the automotive market'. Reinforced plastics. 30 Jul 201230 Jul 2012: n. page. Web. 12 Dec. 2013.

3 Sloan, Jeff. ‘Car composites quest: One-minute cycle time?'. Composites World. 01 08 201201 08 201201 08 2012: n. page. Web. 12 Dec. 2013.

The utilisation of a gel coat allows the obtaining of pieces totally finished without need of the application of back phases of painted. The utilisation of a gel coat in dust presents additional advantages with regard to the utilisation of the, employed at present, gel coat liquid. Between these advantages fits to stand out the important reduction of time of cycle (between a 70 and 88%), the possibility of reuse of the excess of gel coat in dust applied using systems of aspiration of dusts, a greater effective performance in grams by surface of material applied (1:4), a greater quality of the pieces since it improves the interfase gel coat – resin and a reduction of the broadcasts of volatile organic compounds in the plants of production.

The design and manufacture of a mould with ‘leathers' interchangeable with a structure of fibre of carbon that acts like support but also like element heater is another of the challenges of the project. The utilisation of these moulds ensures a warming homogéneo of all the piece to the necessary temperature for the learning of the film of gel coat and with the superficial quality required in the sector of the automotive sector ‘surface Class To'. Besides, it foresees the utilisation of preformas to improve drastically the speed of current production.

Finally, will employ two cases of study to show the advantages of the the new technologies developed in the project; a piece for the sector of the transport of heavy commodity and a piece for light vehicles. In the first case, the piece will obtain with the coating of the gel coat in dust of the colour of the final finishing, without need of back treatments. The piece to realizar for light vehicles, will obtain with a coating of gel coat in dust with properties of ready electrical conductivity for his painted in a bathroom of painting cataforética as it is usual in the painted of metallic pieces.

The consortium of the project is constituted by 13 European organisations that include, Aimplas, Ecoinnova and Cidetec in Spain, Composite Integration, Axon and NetComposites of United Kingdom, Clerium of Holland, Indupol International N.V. Of Belgium, and-Xstream engineering of Luxembourg, ‘Dortmund University of Applied Sciences and Arts' in Germany, Ketek in Finland, Megara of Greece and Steel Belt Systems Powder Coating Division (SBS) of Italy.

The investigation that will drive to these results has received subvention of the 7º Program Mark of the European Union (FP7/2007-2013), under the agreement of subvention no. 609203. For more information can visit the web of the project in