Interview to the professor Dirk Biermann, of the ISF of the Technical University of Dortmund, Germany

Professor Biermann, with what material can do a lighter car and, therefore, lower in broadcasts?

The increasingly strict norms of the politics are subjecting to the industry of the car to a big pressesure, what forces to the manufacturers to use material lighter and to optimise the combustion. If it reduces the size of the engine, reduces at the same time the weight of the vehicle. An engine of four cylinders has today day an alike power to the of six ancient cylinders. This only achieves with turboalimentadores or compressesors and optimising the process of combustion. The problem is that the components suffer an a lot greater load and need steels of very high resistance. The designated steels bainíticos, for example, answer to these exigencias.

The steels bainíticos, so that pieces of the vehicle use and of which conditions depend?

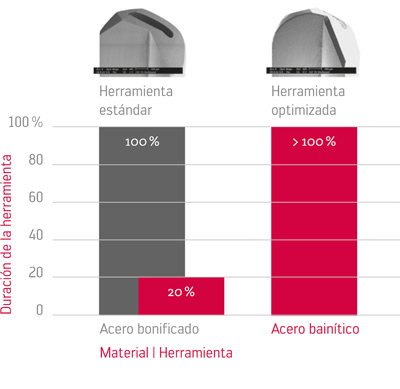

The steels bainíticos can use for bielas, crankshafts and, especially, for systems of injection diesel. When they mechanise these steels, the tools subject to a big load termomecánica because of the big resistance. Therefore it experiences our institute with materials of cutting and appropriate coatings that resist these loads. Also we optimise tools regarding his forming, for example for the taladrado of deep orifices, so that they resist better to the solidest materials.

This is not everything in what it is investigating. What material follow giving headache to the industry of the mechanised?

For the components of the engine and of the chassis can use likewise material of titanium, that also are very light. And also with the titanium wear out the tools with rapidity, especially by the high thermal sensors load. For this reason it bets the ISF by the cryogenic cooling of the process with CO2, in which from a filter projects a mix of fine particles of carbon dioxide and gas of CO2 to -78 °C that gives in the point of start of shaving. We call it the chorro of snow. With the cryogenic cooling also can reduce the proportion of oxygen in the zone of virutaje and, therefore, the chemical reactions of the material with the oxygen of the air acclimatise. Finally, with the cryogenic cooling can improve likewise the break of shaving.

In the turning and the taladrado is the sharp edge continuously in action, by what, in extreme case, produces an only long shaving that it can roll up around the piece of work and also is dangerous for the operario of the machine. If it cools the material with CO2, the materials easily deformables go back more fragile and the shaving breaks before. The particles of snow possess besides kinetical power, what mecánicamente facilitates the break of shaving.

The industry of the car is processing already steels bainíticos and alloys of titanium?

The steels bainíticos are in phase of development and are testing especially in systems of injection of motors diesel. The materials of titanium are applying up to now only in the aeronautical sector component manufacturing sector component manufacturing and in sportive vehicle of luxury. Until we can see these materials in the vehicles of half range, can happen some time.

Cooperation between ISF and Walter

At present, the Institute of Technology of Mechanised (ISF: Institut für spanende Fertigung) cooperates with Walter in a project for the machining with chip extraction equipment of steels bainíticos of high hardness. Besides, Walter has foreseen to participate also in the investigations of the ISF for the cryogenic turning of materials with base of titanium and nickel and develop systems of tools adapted to this new enfriamento of process. Another project of cooperation works with the complete manufacturing of complex tools for start of shaving to end to increase his performance.

Steels bainíticos

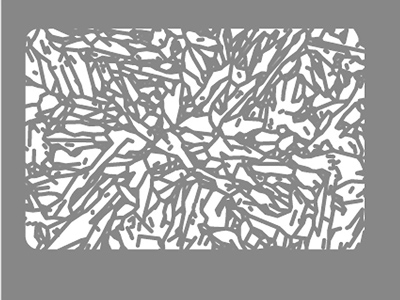

The bainita produces in the thermal sensors treatment of steel to the carbon by isothermal sensors transformation (in which the temperature keeps invariable) or by continuous cooling. This treatment designates also bainitizado. The fine distribution of carbide that reaches in this process provides excellent properties of resistance and tenacity.

cryogenic Cooling of the process

The cryogenic cooling in the designated chorreado with snow of CO2 consists in rociar the point of start of shaving with a fine fog of liquid carbon dioxide. To temperatures of -78 °C, form glasses of snow of CO2 in the filter of exit of the edge of cutting. With this process improve notably the length of the tool and the data of cutting.