The revolution of the milling of gears

The sector of the automotive sector will be a ‘Focus' for Sandvik Coromant, what means that it already exists a plan of action and strategy to global level for the improvement of the applications that give in the manufacture of components. Like this it defines it Kenneth Sundberg, global director of development of business for solutions of milling of gears of Sandvik Coromant: “what seemed impossible eighteen months ago is now a reality that takes place daily”. A sentence that resume the efforts of development of the company in an area of technology relatively new for this manufacturer leader in tools of cutting.

Around the year 2005, Sandvik Coromant saw the need and the potential of change in the performance of the milling of gears. In effect, the technology of the machines-tools and of the software, as well as of the applications of the industry, began to evolve, and also did it the solutions of tools of cutting. The strength motriz after this change of the tools enterizas of fast steel (HSS) to the tools of plaquita interchangeable was the research of an increase of the productivity and the useful life of the tool, as well as the elimination of the need to go back to recubrir and reacondicionar the tools. All these factors are, nowadays, an indispensable requirement for the world-wide market, increasingly competitive, of the commercial vehicles like the trucks, the agricultural machinery and the heavy machinery, such as the machines of explanación and construction.

Changing the game

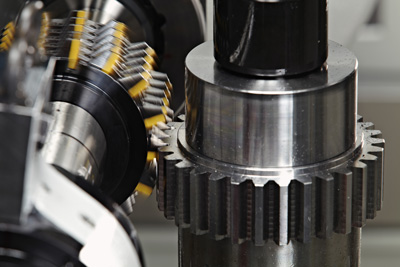

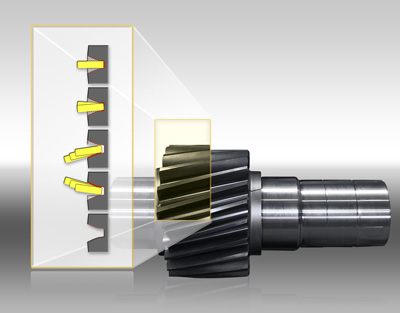

With this new concept of strawberry mother, CoroMill 176, Sandvik Coromant has stepped of giant in the technology and the performance of the milling of gears. The new adapter, slope of patent, between the plaquita and the tool has provided to the tool a greater level of precision and rigidity, as well as greater speeds of start of shaving and a superficial quality optimised.

The speeds with which operates are entirely new for the industry of the milling of gears of commercial vehicles. In fact, in Sandvik Coromant can even bend and, in some cases until triplicar, the results with CoroMill 176. Besides, the use of the tool holders Coromant Attract adds robustness and stability to the tools of milling.

The developments of tool, such as CoroMill 176, are the result of a narrow collaboration with a group selecto of manufacturers of gears and machines-tools leaders of the sector that have fixed very high requirements. These companies value very positively the increasing competition between the manufacturers of tools of mechanised and, especially, the fact that the tools of plaquita interchangeable now are available to accommodate a greater range of gears.

Nevertheless, is just to say that some show skeptical regarding if the tools of plaquita interchangeable will be able to provide the narrow exigencias of precision required for the transmissions of high speed employed in heavy vehicles.

Sundberg Explains it like this: “while the ambition was here from the beginning, had my doubts on if we could offer solutions for this so prompt application as in 2012, mainly because we have been competing with tools enterizas of rectification of precision HSS”. But, in fact, in these moments adjust us to the quality 9 (of compliance with DIN) of regular way and, in favourable conditions can attain until the quality 8.

Splits of this impressesive performance is due to that the tools of Sandvik Coromant supply with the plaquitas mounted and with a protocol of measurement of compliance with DIN 3968. Of course, to be able to reach these levels of quality of consistent way, the back changes of plaquita have to llevar in some clean surroundings and by qualified operators.

A new approach

Sandvik Coromant Goes in in the field of the milling of gears with a new perspective, a solid technological base and a wide experience like leader in the industry of the mechanised, for retar to the methods and existent means of the sector. An additional advantage is the fact that Sandvik Coromant can offer a skilled team in the milling of gears that provide a system of global support. Thanks to this, the manufacturers of gears for trucks and heavy machinery can have the support of Sandvik Coromant for his business, from the initial investment until the handle daily of his machinery.

The ambition is to expand the offer the fastest possible and supply better levels of service to end to have the best and more complete offer of the market and provide a skilled support for the industry of the milling of gears in any part of the world. Nowadays, Sandvik Coromant can cover the milling with strawberry mother from the module 4 until the 18. And, to finals of 2012, the company expects to cover from the module 3 until the 30, thanks to the interchangeable solutions.

Sandvik Coromant Wants to offer to the customers of heavy vehicles and machinery weighed the opportunity to take out the maximum split to CoroMill 176 putting to his disposal sizes of module from 3 until 9, specific for the industry of the commercial vehicles. It exists a big potential of saving with the application of this concept. In the majority of the cases, can reach a reduction of the length of the cycles of cut of around 50% in front of the existent solutions in the industry. Likewise, this reduction of the cycles also sees reflected in the reduction of the costs, thanks to the increase of the 300-500% of the useful life of the tool; doing so the transition to the technology of plaquita interchangeable was very beneficial. In the mechanised with strawberry mother of gears of lower size, where, to date of today, only are available the milling cutters of fast steel, the profits are a lot greater. Besides, this new solution allows to delete the costly and heavy logistics of reacondicionamiento and coating of the tools.

Growing and advancing

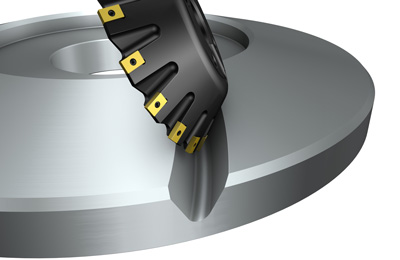

Sandvik Coromant Already has of an extensive offer for the milling of gears. Nevertheless, the new methods uP-Gear and InvoMilling are waking up a big interest in the manufacturers of batches of small to average by his flexibility of mechanised with high levels of productivity and his low costs, thanks to the use of standard or similar tools to the standard.

The narrow collaboration initiated in 2009 with the manufacturer of machines-tools Heller and with Voith Turbo, German manufacturer with interests diversified in markets like the one of the heavy vehicles, gave place to the flexible solution of milling uP-Gear, entered around the middle of 2010. A development that, thanks to his flexibility, is excellent for the creation of prototypes and an interesting alternative to the existent solutions. From September of 2011, Gleason did charge of the sales of this solution in machines Heller, of those who are the exclusive collaborator of mechanised. The solutions like uP-Gear and InvoMilling already are attracting to a big variety of manufacturers that mechanise gears and/or components with integral gears. These methods can arrive to revolutionise this type of manufacture of gears.

Although the initial solution of Voith-Heller was designed for trains of transmission, Sandvik Coromant has developed the solution of mechanised uP-Gear so much for the milling in hard as in soft (by what can delete the rectification). At present, you mill them mother are available from the module 3 until the 20, and the disks for gears and slots from the module 3 until the module 50 will be available to finals of 2012.

But this no everything. To explore and develop more in depth the solutions of milling of gears, Sandvik Coromant has access to the machines of last generation of Höfler and Heller in his centre of application in Sandviken. Besides, we have a narrow collaboration with Zeiss, regarding metrology, as well as with providers leaders of solutions of software inside the design of tools.

The industry of the manufacture of gears is a very skilled industry and Sandvik Coromant has learnt that everything turns around the generation of specific profiles of gears. Thus, to offer the necessary means to mechanise these profiles, all the tools are special. Nevertheless, we have entered a series of plaquitas of standard profile for the mechanised with strawberry mother of compliance with DIN, together with some plaquitas standard for the desbaste with milling cutters of disk.

Big savings

Finally, appreciate big savings when substituting tools in existent equipment, with savings, in some cases, until of 80% of the times of mechanised. The result is that we can offer to the manufacturers of gears of commercial vehicles, that need a greater capacity, a new tool of mechanised.

The production on a large scale of gears through the mechanised with strawberry mother provides an increase of the productivity, the elimination of the need to go back to reacondicionar/recubrir the tool and the possibility to apply a mechanised without refrigerante. The mechanised without refrigerante has been received very positively thanks to the additional reduction of costs and to the optimisation of the surroundings of the operator. An additional motivation is that the shavings without refrigerante mean greater prices of the material of waste for the recycled.

If up to now the jump of the plaquitas HSS to the plaquitas interchangeable had not taken place for the milling of gears with strawberry mother because the technology was not available, now already is it.

Quotation aside deserves the new line of disks for milling of crankshafts that already is implementing to global level. In all the fields, are putting resources to optimise the processes and do them more profitable and competitive for our customers.

On the other hand, stand out the special obstinacy of the company in improving and speed up the internal channels of communication of such way that the information of the new developments arrive to all the countries of the world and all can benefit of them. For this have formed international equipment, as it is the case of the region of EMEA and that from does months is working in this sense.