On-line thermography for the control of quality of pieces

The temperate of the moulds is one of the critical parameters in the moldeo by injection. The distribution of the temperature in the mould influences decisively in a possible deformation and in consequence in the quality of the pieces injected.

Thus a high constant quality in complex pieces requires of a temperate uniform in the distinct segments of the mould. The on-line thermography allows the detection of fluctuations of quality in each injection, combined with an immediate regulation of the temperature whenever they exceed the margins of tolerance. This “hygiene in the quality while the piece is hot”, has been possible by means of a species of “photography” of the temperature in the surface of the pieces moldeadas, by means of a camera of infrared, taken directly after the desmoldeo.

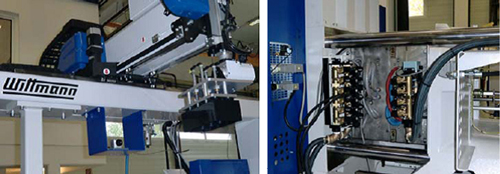

The group of data is analysed later with a special software. To realise this process, the piece presents to the camera in different positions with help of a linear robot immediately after the desmoldeo. The evaluation is showed in a monitor, and all deviation of the state checked is visualised and calculated in individual segments, so that a control of automatic discharge of water connected to the system, for example a team Wittmann Flowcon, modify the refrigeration to real time.

The advantages of the process

A considerable advantage of this process is the measurement of the external temperature of the piece desmoldada. It does not require of any type of alterations neither additional team in the mould used in each case. On the contrary of the measurement of conventional temperature by means of thermal sensors sensors inside the mould, the measurement termográfica of the piece moldeada offers a series of important advantages:

1. The systems of cameras used are considerably more exact and resistant that the thermal sensors sensors. Thanks to his high resolution, a camera of infrared is able to scan big areas and detect critical points, as for example parts too hot. In case of failure, the camera can substitute in a minimum time, without having to disassemble the mould.

2. The temperate uniform allows time of cycle optimised permanently. This process also comports an improvement in the set up of the production and a reduction of the initial rejections. The uniform distribution of the temperature ensures a sustainable improvement of the quality. The pieces refused because of errors of temperature, detect immediately, what reduces the costs of retales and back claims. An inherent advantage in the statistical monitoring of the processes, is the capacity to realise the service of the moulds in suitable times and like this avoid unforeseen repairs. And finally, the ‘thermal sensors footprint' (thermal sensors image) trazable is an important parameter of process.

3. The ideal combination of a machine servo electrical Wittmann Battenfeld series EcoPower, with a system termográfico on line, automated with a robot of last generation Wittmann series 8, achieves an upper quality controlled, hardly surpassed by other much costlier technologies.

4. The system of manipulation exerts an important paper in this case. Only with a positioning of high precision and repetible is possible to attract the images with accuracy and compare them with the state wished through the software SKZ. The servo technology controlled through the software R8 of Wittmann allows the realisation of the extremely exact movements and repetitive.