The shortage of innovation defined the 2003 EMO

It is also important to note that, as was heard during the fair, the next EMO fair will be held in Hannover. Paris has gone EMO circuit for what the next (2007) will be held also in Hanover and will return to Milan for 2009 when there will be a new venue to host the event. At the moment it is not known whether there were plans that another city occupy the vacancy of Paris in the circuit.

With regard to the trends observed in the fair the lack of new technologies presented can highlight. Broadly the big manufacturers have opted to complete their product ranges rather than invest in innovative progress.

In this regard include the dual path followed by the manufacturers in their product configuration:

1St machine universal, that worth for almost all types of piece. Aspects such as multifunctionality and modularity are special importance. This point is evidenced by the quantity of products presented by the main Asian manufacturers who have a high modularity and multifunctionality sweeping ranges, at the same time the quality of their machines is increasing, with the increase of competitiveness that are getting in this way.

2Nd machine solution piece. Solution on a single machine and even in a single bound. In this sense emphasizes the integration of processes and products solution piece, sometimes in conjunction with a specific end user and a conception of machine totally tailored to the pieza-objeto in question, even as far as measuring systems and automatic loading/unloading is concerned.

Also large manufacturers complete its offer with the inclusion of simulation of processes in 3D models, and some even give a modular and independent treatment offering them as if a business in itself same were to their packages of software (DMG). In addition to the breadth of product range, are these developments packages software, alarm, aspects of integrated maintenance management, what distinguishes leaders around the world, increasing more and more the "distance" with the rest of manufacturers.

Trends in various technologies

Milling:

It denotes a clear commitment by the 5-axis machining, succeeded in several possible ways: with 2 rotating axes in a rotating swing arm table, with 2 shafts rotating in the head, or, with a head of controlled rear twist and additional turntable. The manufacturers of milling machines seem to have been directed towards the sector of Aeronautics (parts set out in the stands were almost always of Aeronautics) and therefore opted for the high speed. There were two products with hexápodos (M.Torres in collaboration with Fatronik and PARPAS group) but in both cases as not industrializables prototypes in the medium term. They are more demonstrations of technological capability to models for a true industrialization. It has been proved the growing importance of finishing machine and the aesthetics of the final model, taking care with a special emphasis areas such as the comprehensive machine fairings or protections and closure of different shafts.

Differentiation comes by specialization: this could be the slogan of the manufacturers of saws in the EMO. No doubt the main bastions of the sector have opted to offer complete solutions for the machining of profiles. In this way they offer lines of sawing, drilling, punching, plasma cutting, and all this together with the bet by the use of the minimum amount of coolant. It highlights the absence of Kaltenbach and the limited presence of beloved.

Punching / folded:

It is grasping some growth of water in the machining of sheet metal cutting. Stresses the hitherto unpublished incorporation of linear motors in these technologies. Rainer presents the LUX model driven linear on the x-axis.

Other manufacturers provide models to complete range. Laser cutting is also established as an alternative. As for notable absence in this field highlights the limited presence of beloved (only presents a conventional saw) and Trumpf (only presents cutting by laser).

Turning:

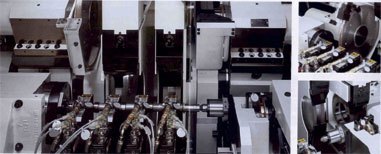

While the competition is very wide major technological developments are not appreciated. Several manufacturers opt for the minimum amount of lubricant and ecology, aspect that in recent years has gained adherents. Interestingly, the incorporation to ranges of products in the family of lathe fresador and increased competition from Asian manufacturers, with a growing competitiveness in quality and breadth of range, as mentioned above.

The centres of turning have been those who have more integrated that aspect of multifunctionality, incorporating turning, milling, grinding, measurement post-processing and automatic loading/unloading. Just the piece in a single bound, and often, on the basis of the process of turning hard. In addition, due to compulsory modularity that involves what we discussed above, they have multitude of controlled axes.

Grinding:

There is a clear trend towards the integration of operations (turning hard + grinding). Tachella presents a prototype in this sense "Grinder Concept". As for flat grinding large manufacturers opt for the inclusion of linear motors in the tables of their focused products in principle to the sector of moulds. Finally in centreless grinding is detected the application of the cheek teeth of CBN (very high cost not always justified by the operation) and presents a model with linear motors and benches of granite (Tschudin). Generally seems that the activity of this type of technology is low and the possible future disappearance of certain parts of the car complicates its viability. Several manufacturers are grinding of double album as a follow-up process.

Machining centres:

The field of machining centres last deserves mention. It is still promoting the creation of machines with parallel architectures (PKM), but they are at the level of prototype rather than intended in its immediate industrialization. In terms of the software, it should be noted that it is a distinguishing aspect of Asian manufacturers, as well as the integration of processes. Finally, note the progressive increase in the use of linear motors as axis drives.