DMU 80 eVo with cambiador of palé: greater productivity and versatilidad

2 May 2012

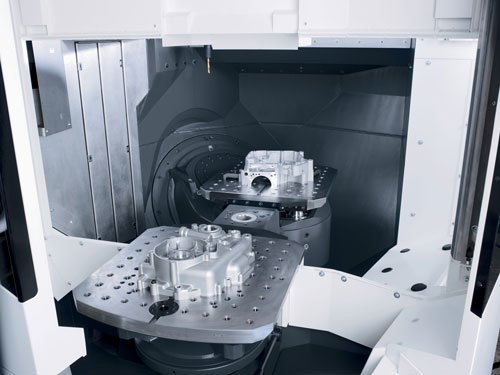

The new generation DMU eVo of Deckel Maho Seebach offers an optimum performance in every aspect, of the that benefits also the new DMU 80 eVo with cambiador of palé. For example, the concept of machine has been entirely revised and now presents in version Gantry, to guarantee to the machine a significant increase of rigidity and precision. The new Gantry optimised, in comparison with the classical version, offers a better lateral accessibility, in addition to an elder visited of the axles, a wider area of work in front of a lower need of space for the installation. However, the successful concept of rotary presses table basculante keeps but the limit of load of the table, the dynamics and the area of basculación have increased of significant way.

Considers the compact structure of the machine, what stands out are the dimensions of the area of work, with routes of 800, 650 and 550 millimetres in X, And and Z. The surface of work of the rotary presses table basculante measures 800 x 700 mm. The table can load until 600 kilos and has a rank of swing of -5° to +110°, that allows cuttings underneath of 20°. Besides, the fast advance of 50 min-1 in the axis B and C confers to the DMU 80 eVo an only dynamics in his class, that can increase still more thanks to the dynamic package: it linear motors in the axles X and And improve his speed of 50 to 80 m/min.

The concept of universal dynamic machine includes also the new cambiador of palés of the DMU 80 eVo, that is integrated cheese cheese of optimum form to the area of work of easy access, without need to increase of considerable way the space of installation of the machine, and stands out by his short cycles of change of so alone 12 seconds. Said innovation goes to find applications in diverse sectors as in the industry of the car and aeronautical sector component manufacturing sector component manufacturing, in the construction of tools or in the medical sector: this machine is the ideal solution for the realisation of individual pieces as for the production in series, in which it offers a very high performance in the mechanised with 5 simultaneous axles.

These characteristics, beside the fast change of tools for time of shaving to inferior shaving to 5 seconds, turn into an advanced package of high technology; the warehouse of tools can satisfy all the needs of the customer thanks to a wide range of components. The double harp guarantees, besides, a change of fast tools and sure.

The different versions of the new DMU 80 eVo offer a lot of possibilities, for example to través a selection of husillos with speeds between 14.000, or optional 18.000 and 24.000 rpm. In the standard version provides a performance until 19 kW and a pair of 100 Nm (each one with 40% ED). Besides, the new engine husillo of 18.000 rpm represents a new characteristic in the module of the husillo, thanks to the lubricación that lengthens his useful life, to the excellent rigidity thanks to an integrated cheese cheese solid axis as well as a cojinete with increase in the capacity of load for a significantly greater resistance. Because of the high reliability of the husillo, DMG offers a guarantee of 7.500 hours of operation.

Regarding the control, the DMU 80 eVo has the DMG ERGOline Control with screen of 19” and software 3D, and the CNC optional, Siemens 840D solutionline with ShopMill or Heidenhain iTNC530, ensure an optimum performance of process and programming.