Supplier/OEM integration accelerates the processes of manufacture

July 11, 2011

Aritex Canding in their Engineering Department develops design tools, as well as that of manufacturing processes. In recent years, the company has implemented the Tecnomatix Process Designer, Robcad and Plant Simulation from Siemens PLM Software, solutions to improve the design and control of the manufacturing processes of the customers.

- Business initiatives

Efficient production

- Business challenges

Reduce development time of robotic assembly lines for new vehicles

Develop more closely integrated processes between supplier/OEM

- Keys to success

A joint platform for collaboration

Data organized, reliable and documented; reports of rapid extraction

Possibility of modficar processes and evaluate alternatives

- Results

Process of manufacturing rapid development, after releasing the final product

Reduce time of development of the vehicle

Standards of quality and reliability

Flow of data between applications

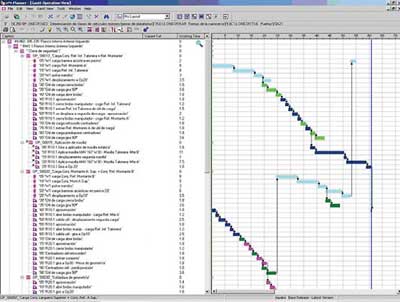

The creation of automatic welding for Automotive OEM lines, is a clear example of how Aritex Canding uses software from Siemens. In the early stage of the project, when a new vehicle is at stage of development, the provider can start defined at the conceptual level of manufacturing processes. Aritex Canding, worked on the premises initial data provided by the OEM, importing operations of work in Process Designer, where began to break down in suboperaciones to allow more detailed analysis of diagrams of time and sequences of operations. Process Designer's Pert, allowed engineers to easily configure sequences of production, while the Gantt chart discussed time diagrams. This ensured Aritex Canding production systems can meet the cycle time targets set by the OEM, while efficiently allocates resources through the Assembly lines.

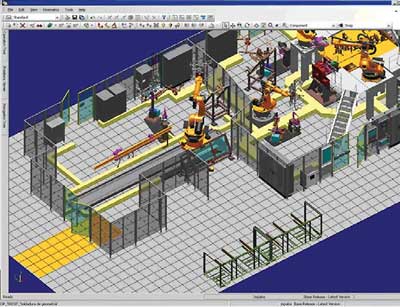

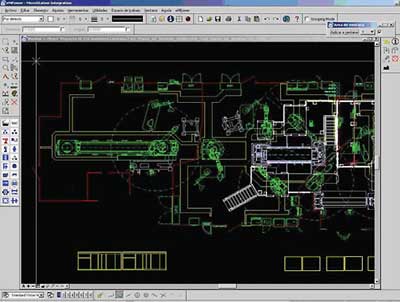

Once defined and sequenced operations at the conceptual level, proceeded to validate most committed processes through the use of the simulation of flows Plant Simulation tool. These simulations allow validating the process designed to comply with the requirements of the OEM, based on several factors including time cycle, dimension of resources, equipment, operators, maintenance, schedules, etc. From the results obtained, and with the integration of Process Designer, each operation is adjusted to ensure that the design of the process complies with the requirements of the client. Using Process Designer, it is possible to visualise at all times the facility designed in 3D to detect possible geometrical problems (collision, inaccessible components, etc). Once validated alternative work, unable to create the 2D layout using Microstation to verify that designed facilities can be placed within the physical space marked by the OEM.

3D generated with Process Designer information can also be exported to Robcad, where to perform simulations in detail of all the processes involved. This makes it possible to verify the accessibility of the robots, balancing points, relocation of resources, etc. Moreover validated geometrically defined process, be it found the cycle time and materialize the final position of the most important components in the layout.

Final version of the data

The customer defines the information of the project, they refined document and complete one of the simulations to reach an optimal solution. The turning point occurs at the time that the final product is released. It is at this time when you must define exactly one designed processes. Due to the tight integration Process Designer, Plant Simulation with Robcad, data are shared and used in multiple domains. This increases the accuracy of the final models.

In the final release of product data, much of the work is carried out by the supplier, who will only have to verify the process designed to end data. This involves a reduction in the time of development of the process from the final release of the product and a very important decrease of the total time of development of the new vehicle. Also, the collaborative use of the tools of Tecnomatix, lets focus on new product development evaluating the necessary data in terms of reliability and quality required, greatly facilitating the development.

Doing this work with Tecnomatix, you get a single source of data shared for the new Assembly processes, allowing the client to extract all kinds of reports and reports at any time. The cooperation between the supplier and the OEM has a direct benefit for the provider, increasing competitiveness, by reducing the lost time by creating duplicate information, and providing great flexibility and quality of communications between the supplier and the customer.

The experience of Aritex Canding with Tecnomatix offers additional benefits for future collaboration in the automotive sector, which will make it possible to progressively refine these working methods to maximize the benefits from the supplier to the OEM.

Aritex Canding expects to see a greater reuse of data from the projects already completed, improved the integration system of documentation with the 'layout' and simulation tools to ultimately adapt internal work processes of the company to the new horizons the virtual factory has now open to the industry.

Aritex Canding takes on the management of the lifecycle (PLM) solution via T-Systems Iberia, part of the Deutsche Telekom group. T-Systems is a distributor of value for Siemens PLM Software. T-Systems offers high quality services by combining information technology and communications. One of its business areas is PLM offering integration of conceptual design, development of product, simulation and analysis, virtual factory, virtual reality and product data management. T-Systems also carries out integrations of suppliers, outsourcing services CAx and provides PLM consulting as well as the implementation of a specific methodology for processes of customers.