Study of new materials for additive manufacturing

Process camera.

Regardless of the operation of each one of them, the most relevant aspects demanded by end users tend to be: price, accuracy, material, surface finish and production deadline.

Among them, perhaps the aspect more important is having lately is the material used for their manufacture; well because the piece will be considered as final piece, either because it is considered as a functional prototype which we need to validate their behavior.

In this sense, machinery manufacturers evolve their processes in order to incorporate the greater variety of possible materials and thus cover the largest number of applications required by the user. Of course, sometimes this is not so simple, because that most technologies are limited for some reason; either by the own process for the production of the raw material, by the process of transformation, process of cleaning, gradient of the material, commercial interest, etc.

Taking into account these aspects, in a joint manner from the area of rapid manufacturing and processes of AIJUarea, focus the study in the search for materials that can be incorporated into the process of SLS (selective laser sintering). We opted for this technology because one of the advantages it has is to admit any material that is likely to be melted by heat input.

The process of SLS is based on the succession of a laser beam scans on a flat surface of material, which are describing each of cross sections of the pieces that we are going to get. The laser then get promptly melt material, so that after the whole process of all sections can separate the solidified material from the rest, getting the physical model.

The acquisition of new materials at the level of laboratory course is different from an industrial process, so in most cases the amount of product to be used is very small. In most cases obtaining also very slow and costly. Mainly because of this limitation, the use of materials test on a team industrial SLS becomes unworkable.

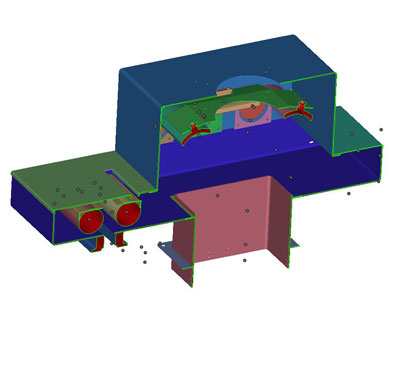

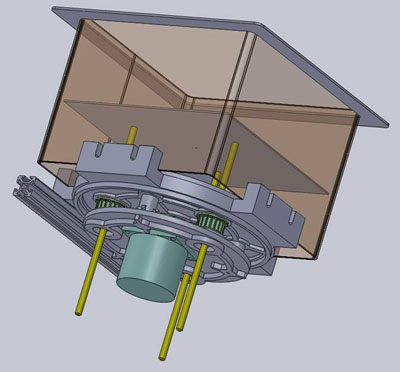

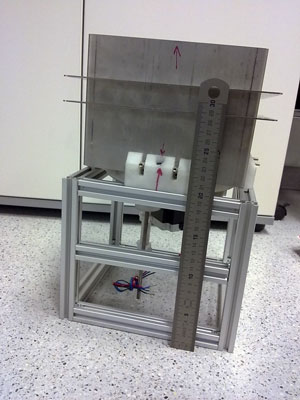

This was considered to make a relationship of similarity on process, developing a machine to do so in sintering at a small scale that enable it to study the behavior of new materials to the action of the laser. Thus, the most important components that they looked for in the new team were:

- Laser

- Scanner

- Thermal control

- Control of food

Cutting process.

Cutting of the roller.

Simulation of the manufacturing area.

The laser to be used is the CO2, with the powerful enough for use on plastic and similar materials. On the other hand, the sharp laser control manages sections swept away, being similar to other technologies. Thermal control of the area of construction to temper the material near their fusion is carried out using heaters and infrared sensors. Likewise, others of the optical type are used to control movements of piston and feed rollers.

It was considered also a manufacturing area of 100x100m, representative minimum to obtain parts model, such as standardized test of tensile, impact, etc. which also serve for further analysis. Thus, the amount of material required to obtain is reduced to a minimum.

Ultimately, through the development of this team seeks to simulate the process of additive manufacturing, but in a lab environment to reduce costs, both in cost of materials, and all this in less time and resources in order to obtain applicable results on an industrial scale.

The range of materials that are in the process of development has as a starting point the current shortcomings existing in the market, such as biodegradable materials, nanomaterials, water-soluble, drivers, etc., although it can be extended to specific needs of an application.

Feeding ground.

Part of this development is framed within the Singular strategic project "ibe-rm" with the file PSE-020000-2009-001, financed by the Ministry of science and innovation, as well as within the regional project with title "Development of experimental equipment for sintering selective laser (SLS)", funded by IMPIVA and co-funded with the EU through the European Fund for Regional Development (ERDF) for the implementation of Rapid Manufacturing in the juguetero sector.

Area of production.