The dental segment, one of the protagonists in the 'Open House' of DMG in Barcelona

November 16, 2010

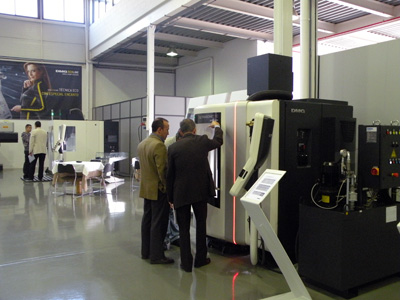

During the three day meeting the company brought together representatives of 92 companies, who could see up close, in full work, up to 8 exposed machines. Among them was the 10 Dental, "a machine that is noted for the accuracy of 5-axis for all applications, with all dental materials", comment from the commercial Department. It's a compact machine, which occupies 2 square meters of base, "with dimensions of 800 x 1,800 mm delivery". Also incorporates an integrated swivel rotary table (4th / 5th axis), with par technology, and -20 ° / + 120 ° of range of inclination. Also, the spindle of high frequency water-cooled with HSK-25 and a maximum of 42,000 rpm series.

In addition, can be automated with a small, integrated automation for 4 media unit or a PH 2 store | 120 linear Alternatively. Supports the integration of a unit of blown / extraction in the spindle and incorporates control Siemens 840 d solutionline for high performance and simple use.

Among other vulnerable machines within the range of turning, saw the automatic lathe CNC Sprint 20 linear. With regard to milling, DMG launched both the Centre of mechanized vertical model DMC 635 V - dash of pallet-like the DMC 1035 V vertical machining center and the machine milling CNC universal for the machining on 5 sides / 5-axismodel 80 monoBlock DMU.

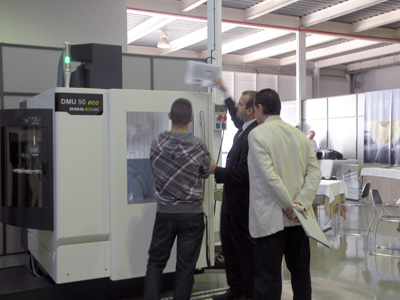

Also, they were also exposed, range DMG Ecoline, universal CNC turning machine, model CTX 310 eco, DMU 50 universal machining center eco and DMC 635 V vertical machining center eco. Together with them, DMG Microset, measuring tools team model 210 VIO.

See the machine working and count on the advice of the commercial Department of the company fosters contacts and allows, as it was the case, a posteriori interesting offers on some of the exposed models.

All the facets for complete machining

Complete machining is the 'royalty' chip startup and is also the most economical answer to reduce size of pieces, terms of delivery and economic pressure. The initial technical level requires machining on 5 sides / 5-axis in milling and the use of motorcades in lathe machining tools. But above all, the "most noble title" reserved for machines of high technology for combined simultaneous 5-axis machining technology of milling and turning on a single machine.

Above all, machines that perform complete machining due its success to the economic advantages which gives them a small chain of process. Prevents transport of parts between several machines and therefore the risk of damage, reduced setup times, simplify the planning of production and reduce time and cost required for the fixation and preparation of operations. Therefore, the machines that perform the process completed provide the way faster and more economic from the design to the finished piece.

DMG has presented its wide range of options for the complete machining of chip startup in the IMTS in Chicago, AMB in Stuttgart and BIMU in Milan, exhibitions showing completely economic machining of various components, from simple applications to more complexcovering different piece sizes and materials of different hardness.

As an example, the DMU 50 model is the economic reference to start 5-axis machining, and also allows to enter a new era in relation to the conditions of cutting tools, fixation of piece and manufacture moulds in workshopstraining centres and laboratories. Innovative technologies and options like digital drives, swivel rotary table to CN with hydraulic locking system and controls of high tech screen TFT of 15 "with 3D software-controlled characterise the impressive performance of this machine. The DMU 50 can be equipped with different types of tables and other options ranging from the simple variant 3-axis to the machining on 5 sides.

With the DMU 100 monoBlock, DMG offers an example of the range of machines monoBlock with unlimited performance and a high degree of flexibility. With 5 axes controlled as standard equipment, options of spindle from 10,000 to 42,000 rpm, Swivel Head controlled axis (b) with a field of rotation of 150 degrees including negative of up to 30 ° and the fast rotating table CN angles, outlining the wide range of machining economic universal (X/Y/Z) 1,250 x 710 machining area x 719 mm and for parts up to 800 kg.

The family of machines duoBlock highlights universal machining 60 DMC or duoBlock Centre. Equipped with a fast pallet changer for parallel preparations, 60 DMC or duoBlock sets a new milestone in machining to 5 axes of high productivity. DuoBlock concept allows to combine productivity and machining 5-axis thanks to the rapid chain store and changer of rotating pallet as well as high-precision rotary table CN and tilt head to CN as optional B axis-controlled. Areas of work, comprehensive and easily accessible from 600 x 700 x 600 mm with minimum space required is the key to its design. Along with the standard pallet changer, duoBlock model also includes different systems of rotating warehouses for four, five or ten pallets as an option.

The programme of the milling and turning machines, DMG also has the 'bestseller' DMC 125 FD duoBlock, noted for maximum rigidity and stability and that, thanks to the universal head tilt, offers perfect conditions for a high precision 5-axis simultaneous machining. The DMC 125 FD machine duoBlock includes a table of fresado-torneado with DirectDrive (direct drive) technology with 500 rpm speed, and a quick dash of pallets for parallel preparations and maximum productivity for machining complete parts with diameters up to 1,400 mm and weight maximum of 2,500 kg.

The future importance of high-speed machining is underlined by DMG with the line of machines HSC (e.g. the HSC 75 linear and the HSC 20 linear). Both HSC machines convince with its unbeatable dynamic and maximum speed due to its linear motors in all its axes with excellent productivity, accuracy of contours and quality of surface with a roughness up to 0.2 Micron finish. With a rotation speed of 42,000 rpm in each case, the conceptual difference between both machines is, above all, the integration of the 5 axes. For pieces of high weight, the HSC 75 linear is based on a combination of axis tilt in the main header and a CN controlled rotary table, while the compact 20 HSC linear used a tilt rotary table equipped with high-torque drives.

As an example of the range of centres of torneado-fresado, DMG displays the CTX beta 1250 TC. 'TC' is the abbreviation for dash of high-speed tools that, together with the drive integrated in the machine store, ensures maximum flexibility and reduction of tool change times. The heart of the CTX beta 1250 TC is the mobile column that integrates the header for torneado-fresado with B axis which interpolates. This allows to perform both operations of machining and turning complex 5-axis simultaneous milling with a high efficiency mode. As option, the center of turning can be equipped with a subcabezal, which in this case allows even machined 6 sides in a single preparation.

Many of the machines can be equipped with Ultrasonic technology for machining of hard materials. For this purpose, the high-frequency ultrasound is transmitted by induction from the head to special actuator accommodation HSK. This makes it the tool of diamond, which is adapted for carrying out the work in particular, to oscillate. In this way produces a burst of chips of the smaller particles on the surface of the workpiece, and complex elements can be machined and finished in a single process of machining.