Tiger·TEC, a step beyond the chip startup

March 30, 2010

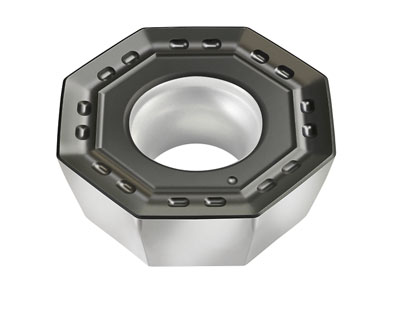

Extremely stable cutting edges to ensure greater security in the processes, the arrancadora surface of chips is very smooth, for optimum resistance to wear by contact. Addition, the incidence of silvery surface enables easy recognition of wear during application.

Advantages of this technology is its great hardness and minimum formation of cracks perpendicular to the cutting edge with optimum residual stress with wear minimal contact since the rompevirutas surfaces are smooth and perfect. In addition, it is resistant to thermal variation in dry and wet machining.

Cutting material: efficiency without limits

With the materials of court Tiger·tec Walter Tools are establishing years new patterns in regards machining with chip detachment. The new material of court Tiger·tec Silver is another giant step on the path to perfect cutting material. It is suitable for dry and wet machining applied in automobile and construction of rail vehicles, energy technology, in the manufacture of moulds and dies, in technology Aeronautics and aerospace and construction of machinery in general.

Arrancadora shavings surface is very smooth, for optimum resistance to wear by contact.

Sectoral solutions with force of incision

Specialists in engineering of the company known for decades more sectors to fund and this, together with the knowledge, experience and the ability of listening, have made it possible to achieve success in their work of engineering. Thus, with an average of 75% performance increase, new material of court Tiger·tec Silver enables Walter Tools engineers develop processes of chip startup more efficient and productive for machining in dry and wet of steel and cast iron parts.

Each sector, each piece and each material has its peculiarities in regards to the processing.

On the other hand, the new plates of court Tiger·tec Silver deployed a force of incision extraordinary, guaranteeing maximum values of court in everyday use and, consequently, greater cost-effectiveness in machining with chip startup at any time and place.

Technology Tiger·TEC Silver: totally innovative CVD technology

In addition to the special combination of the coating, the new Tiger·tec Silver technology implies a totally innovative surface treatment. The optimum residual stress results in increased sobreproporcionado of the hardness of the material of the Tiger·tec Silver wear-resistant cutting. This combination of high resistance to wear and maximum hardness is that gives the material Tiger·tec Silver an extraordinary power in the detachment of chips.

The new plates of court Tiger·tec Silver deployed a force of incision extraordinary, guaranteeing maximum values of court in everyday use.

Strong, safe, superior

"The role it holds everything, but clients do not." "They want pieces of high quality at competitive prices." Aware of this, Walter Tools engineers have challenged to the competition in many comparative tests with the new material of court Tiger·tec Silver. And the result is convincing. In the milling in wet steel discounted 42CrMo4, as that is usually used in the construction of vehicles, Tiger·tec Silver achieved an increase in the duration of 70%. Tiger·TEC Silver exceeds this way not only to similar products from other vendors, but also to court materials Walter Tiger·tec WKP 35. Comparative tests have shown that Walter's Tiger·tec Silver continues the success story of the Tiger·tec technological brand and has all the characteristics that define a reference product.

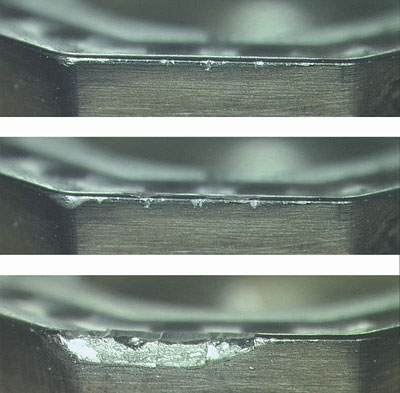

In the picture you can see how:

- The high degree of resistance to wear, toughness and heat resistance prevents the formation of cracks perpendicular to the cutting edge of cutting and breakage.

- The insert of court takes longer. The uniformity of the symptoms of wear and a minimum formation of cracks perpendicular to the cutting edge demonstrate ability of legendary material of court Tiger·tec.

- Products within the province show a clearly visible and intense wear of the edge of cutting and major breakage.

Images of close-up of the phyla of court after the milling of steel discounted 42CrMo4 are clear proof: with its revolutionary coating, Tiger·tec Silver supports easily high cutting speeds without showing significant signs of wear. For the company, the conclusion is clear: "Tiger·tec Silver is, with an increase in average performance of 75%, the new leader among the materials of court".