DMG faces the year 2010 based on innovation, despite everything

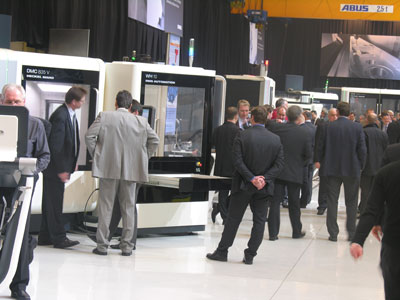

The ability to call for DMG is impressive. More than 4,000 visitors in 5 days in lean is a figure to applaud and the activity in the corridors of the surface of the plant dedicated to the exhibition of machines was notable, as it was in the area of the bar that the German company organized just in the middle of the machines.

In the meantime curious and interested in technology, could not miss the press, received by the primary responsibility of Gildemeister. Rüdiger Kapitza, head of the Executive Council of Gildemeister AG began his presentation by placing this internal fair holding in the context of a very depressed economy. According to their data, orders for machine tools in 2009 fell in a 66% Europe, an average exceeded by Spain, for example, that, according to r. Kapitza, contracted by 73%. In Europe not was saved no one, certainly, but countries such as China, India, Brazil and Russia are immersed in an upward trend that is developing. Nevertheless, Gildemeister finished 2009 in black numbers.

The seminars held to the length of the days also give an idea of the topics that interest today to this large consortium: aerospace, that of the automobile, the doctor and dental, known here as "turn & mill" (milling and tornado) and the Court at high speed.

As major themes in the strategy of Gildemeister is its penetration in the field of large machines, energy efficiency, the approach to the market and cooperation. In relation to this last point, the most important step of recent years was the relationship initiated with Mori Seiki in 2009, a cooperation which, as said r. Kapitza, progressing positively and is bringing many benefits to both companies. "I have learned more of machine tools in a year than in the last hundred," joked r. Kapitza.

Mosahiko Mori, President of Mori Seiki, for its part, could not avoid referring to the crisis that has plagued this signature harshly. "After a good year 2008 - he said - 2009 was a terrible year, we closed with losses and that we were making some 200 machines per month, a figure which we hope that in 2010 will increase to the monthly 400." "In fact, right now we are making around 300 to 350 machines per month". [data on February 2, 2010].

For DMG official responsible for speech tends to be accompanied by data, especially which refers to the r & d. It is likely that it is not anyone in Europe which not has decided already in many cases the argument of the bet by technology to survive. DMG too it, but if the data speak for themselves. "In 2010 - said r. Kapitza - will have submitted 17 innovations." The client needs them and if something we have to save, of course will not be in this. "It is our future".

There is no doubt that the agreement DMG - Mori Seiki has a great influence in the section research and development because of the collaboration of two of the most important manufacturers of machines in the world can get real good things. It is also true that it is not entirely clear what is really this collaboration, at least in the technological. Various Asian countries are already tackling the market under the joint brand DMG Mori Seiki, but both companies are accessing each country according to their particular characteristics.

In any case the President of Mori Seiki, Mosahiko Mori, said that by the end of this year there will be already common production platforms.

And not other data must be forgotten: the two companies together have over 1,000 professionals for engineering and the r & d of machines.

Where are we going?

It is difficult to summarize the innovations of a company of this size, but yes you can put that some topics are those which are of particular concern to leading manufacturers.

One of them is without no doubt the energy efficiency and the other, the potential of the holistic supply chain optimization advantages.

Energy efficiency

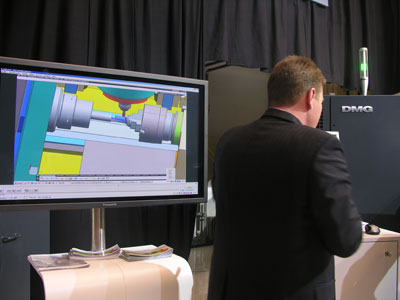

Under the label Energysaving DMG, DMG offers new tools for software and services that allow to optimize the energy consumption in the development, manufacture and the use of machine tools. The virtual machine of DMG, for example, is a crucial element for improving energy efficiency in the process of starting chips and productive sequences. It is a tool to check and, if necessary, optimize CN programs before actual machining, thanks to a 1: 1 of the real machine virtual image. This ability to check and plan the sequence of processes and production with the virtual machine helps minimize configuration and preparation time, as well as reduce defective parts. The use of the machine is improved thanks to the reliability of the calculation of time per piece. Some examples of tools to save energy are as follows:

DMG Greenmode is a software tool created to save substantial amounts of energy during the boot with an adaptation of the cutting parameters to the demands of the process.

Control configurable by customer DMG Autoshutdown system not leaves the machine in its operational status when machining has been done, as usual, but it puts the machine in a break with a reduced power consumption mode.

The EnergySave tool serves a similar purpose, but instead of making the "shutdown" through a function of the control, is carried out with a separate kit that can be connected to any machine tool, without exception.

More recent innovations include machines of the Gildemeister Sauer GmbH, as for example the 10 Dental, presented as an important step in the production of pieces so far had been made by hand. Ultrasonic technology offers the efficient machining of new materials such as zirconium oxide. On the other hand, the integral combination of tools for milling of high speed and the design of the 10 Dental as a five axis machine opens a whole range for machining of materials used in the dental sector.

Also drew attention to the model Lasertec 50 PowerDrill, also coming from the range of Sauer. This machine's five axes for laser drilling has been specially designed for machining small turbines in the aerospace sector. It is a very compact machine (occupies 4 m2) that responds to the demand of customers, giving more and more importance to the surface before a machine. It is equipped with the Lasersoft PowerDrill software created for this machine. Like the predecessors, thanks to a new optical system, the size of the focus can be changed without moving the focus point. Depending on the application can be equipped optionally with ND: YAG of high quality, CO2 and fiber laser, allowing a precision of 8 µm.

To walk or not ande…

It is great, is important. Large machines are another focus of attention of DMG in recent times and shows it with their milling DMU 600 centers and its Center for turning/milling CTX delta TC.

For the first time was the concept of the new machine gantry DMU 600 P, with DMG, the largest of the DMU P series, specially designed for the manufacture of large moulds and dies for the automotive industry. Great sturdiness ensures great precision and dynamics in the work of pieces up to 25,000 kg. The sealing surface of 2500 x 4,000 m located in a compartment of encapsulated machining is generously dimensioned for the machining of moulds for large pieces.

For the sector of the automobile, machines DMC 75 H duoBLOCK and DMC 55 H duoBLOCK have been adapted to the requirements of a specific system for the manufacture of various oil sumps Great Wall Motors (GWM) for the Chinese manufacturer. Machines convinced GWM, which placed an order for 18 machines. Both machines do not have with a pallet changer, but with a loading station designed expressly for the specific production of the client. In the future the client use the fourteen DMC 55 H and four DMC 55 H in three shifts to produce about 200,000 oil sumps annually.

Following the large machines, in the third quarter of this year 2010 DMG enters the market of great centers of turning/milling with CTX models delta 4000 TC and CTX delta 6000 TC. Length of turning 4,150 mm and 6,150 mm respectively and a maximum diameter of turning up to 1,070 mm these two innovations will extend the limits of this series of machines. Moreover, since there is an important date: 10-March 12, 2010 will be held an exhibition of large machines from Gildemeister Drehmaschinen GmbH (Lathes) at its facilities in Bielefeld (Germany), which will constitute the official launch of the further development of a model CTX.

Series CTX also highlights the Gamma 2000 model TC, equipped with Shop turrn 3 G third generation, which reduces the time of programming in 60%.