Double degassing to facilitate recycling

RECYCLING

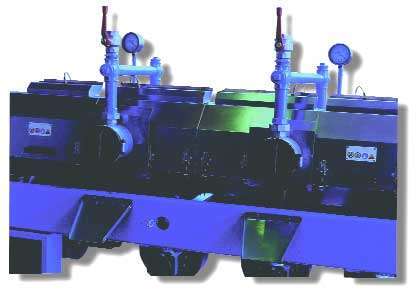

In response to this demand, the Italian company OMP has released a complete plant for the recovery of PE/PP film with many impressions, using an extruder of 85 mm diameter with double degassing, which could already be seen in the latest edition of the K'2001 in Düsseldorf.

Thanks to this type of extruder, mainly due to its dual system of deaerating, molten material is a time of great length, more than the simple degassing. In addition, the effect of drying out is enhanced by the fact that between the two points of vacuum, the spindle is not cylindrical but then compresses the material causing the gases still present inside after the first degassingthey are released and successively expelled in the second degassing (getting rid of the gas still present within it after the first degassing and then expelled by the second desgasficación.)

Another important feature of this configuration of the spindle is that, with a total of three zones of compression, the homogeneity of the material increases, allowing the addition of additives such as antioxidants, peroxides, etc.

The extruder is suitable for treating materials such as PE, PP, PS and ABS, and especially the PET.The diameter of the spindle of the extruder proposed by OMP for this type of installation are 85, 105, 130 and 180 mm, with a length of 40 d.