This news article was originally written in Spanish. It has been automatically translated for your convenience. Reasonable efforts have been made to provide an accurate translation, however, no automated translation is perfect nor is it intended to replace a human translator. The original article in Spanish can be viewed at La potencia del láser, decisiva en los prototipos sinterizados

According to a study of the influence of different experimental variables (I)

The power of the laser, decisive in the sintered prototypes

Louise Vidal, Asunción Martínez

Dept. engineering product and testing of AIJU - proyectos@aiju.es15/04/2002

Dept. engineering product and testing of AIJU - proyectos@aiju.es15/04/2002

The process of a product design is a combined effort of engineers, industrialists and specialists in human factors to consider social aspects and environment, which should be concluded with new products even at the level of prototype. AIJU carried out a study of the materials used in the selective sintered by laser, to create a technical database that allows to know which parameters are adequate for an optimum prototype at any time. This article sets out the first part of the results of the study. The second will be in the next issue of plastics universal.

The toy industry raises developments year after year, thus, needs tools able to provide quick and effective solutions. Therefore, that the use of new technologies of rapid prototyping is increasingly more noticeable within the toy industry because, the fact to be able to predict in advance the success of a given product is a significant economic savingsboth manufacturing costs and possible subsequent rectifications.

A study was undertaken in AIJU of materials used in one of the technologies employed in the sector of prototyping, in particular of the selective laser sinter. In this study, conducted in the framework of a final project, was carried out the characterization of different material sintered by varying the conditions of the process in order to create a technical database that will allow us to know what parameters are adequate for a prototype with the necessary conditions at a certain time. In this way, we can build a prototype with specific properties, i.e. more or less hard, resistant, flexible...

Among others, have been considered polyamide materials and different variables of work of the team of selective sintering Sinterstation 2500 Laser System: power of the laser and the temperature of work, given that they can determine the characteristics of the obtained pieces.

This first part sets out the results obtained with polyamide materials and the influence of the power of the laser of sintering in the final mechanical properties of the sinterizadas pieces. In the second part of the work will be showcased the results of the influence of the temperature of sintering polyamide materials and a third party there will be a comparison of the properties of sintered polyamide using the optimal values of the two studied variables, and injected commercial polyamide material. This comparison was done in order to validate the obtained parts using SLS versus those produced commercially by injection.

A study was undertaken in AIJU of materials used in one of the technologies employed in the sector of prototyping, in particular of the selective laser sinter. In this study, conducted in the framework of a final project, was carried out the characterization of different material sintered by varying the conditions of the process in order to create a technical database that will allow us to know what parameters are adequate for a prototype with the necessary conditions at a certain time. In this way, we can build a prototype with specific properties, i.e. more or less hard, resistant, flexible...

Among others, have been considered polyamide materials and different variables of work of the team of selective sintering Sinterstation 2500 Laser System: power of the laser and the temperature of work, given that they can determine the characteristics of the obtained pieces.

This first part sets out the results obtained with polyamide materials and the influence of the power of the laser of sintering in the final mechanical properties of the sinterizadas pieces. In the second part of the work will be showcased the results of the influence of the temperature of sintering polyamide materials and a third party there will be a comparison of the properties of sintered polyamide using the optimal values of the two studied variables, and injected commercial polyamide material. This comparison was done in order to validate the obtained parts using SLS versus those produced commercially by injection.

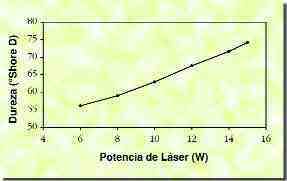

Figure 1. Variation of hardness Shore D depending on the laser power.

Influence of laser power

The parameter of the laser power (6, 8, 10, 12, 14, 15 watts) in the pieces once sintered in order to obtain the value of the parameter with which obtained better mechanical properties has been studied in the first place. In all cases has been used a temperature of 176 ° C.

Here are the results of tests obtained for each of the materials, as well as the conclusions on the most appropriate value of the laser power for certain mechanical properties in the material.

Here are the results of tests obtained for each of the materials, as well as the conclusions on the most appropriate value of the laser power for certain mechanical properties in the material.

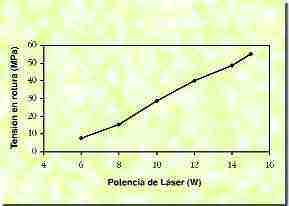

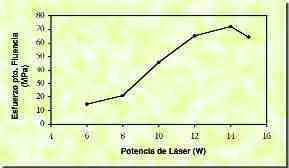

Figure 2. Variation of voltage breakdown based on the laser power.

Hardness Shore D

Results from hardness Shore D polyamide without loading are shown in Figure 1. There is clearly a trend to increase the hardness, as it increases the power of laser. You can see that the highest values of hardness are obtained with powers of laser from 12 W, fact that indicates that the layers of the material better, solidify presenting a higher hardness with high laser powers.

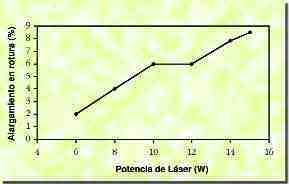

Figure 3. Variation of elongation at break according to

the laser power.

the laser power.

Traction test

The following properties in traction have been identified with this essay: the tension in the breaking point, the elongation at break and the module of Young or elastic modulus. These properties allow to know the behaviour of the material when you are subjected to axial efforts. In Figure 2. shows the effect of the power of laser in the rupture voltage. As the value of the laser power increases, the tension supported by the test tube before breaking too it getting best results with the highest powers between 12-15 W. The same trend can be seen with the elongation at break (Figure 3). To increase the power of laser material stretches more and this value is higher with 14-15 W values.

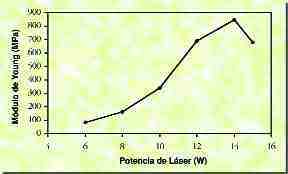

Finally the Young's modulus results are included in Figure 4. The obtained values also have a tendency to increase as makes it the laser power, indicating that the material is becoming more rigid.

Finally the Young's modulus results are included in Figure 4. The obtained values also have a tendency to increase as makes it the laser power, indicating that the material is becoming more rigid.

Figure 4. Variation of Young's modulus in function

the laser power.

the laser power.

Compression test

Figure 5 shows the variation of the effort of compression at the point of fluency depending on the laser power. The results are similar to those obtained in the trial of traction, i.e. There is a tendency to increase the values to the laser power increases. Therefore the polyamide presents enhanced resistance to compression with values of laser power between 12 and 15 W.

Figure 6 shows the results for the deformation in fluency, i.e. the change of dimension which undergoes the test tube in the direction in which the force of compression is applied. You can see how the higher values that exceed 25% of elongation are obtained with high laser powers (12-15 W). While powers between 6-10 W barely exceeds 15% of total elongation. Therefore a greater power of laser material confers greater elongation.

The values of the compression module are shown in Figure 7. Also in this the values of the compression module have a tendency to increase and to do so the laser power. Therefore, the polyamide sintered with a value of between 12 and 15 laser power W presents a greater rigidity showing a sintered with a lower power.

Figure 6 shows the results for the deformation in fluency, i.e. the change of dimension which undergoes the test tube in the direction in which the force of compression is applied. You can see how the higher values that exceed 25% of elongation are obtained with high laser powers (12-15 W). While powers between 6-10 W barely exceeds 15% of total elongation. Therefore a greater power of laser material confers greater elongation.

The values of the compression module are shown in Figure 7. Also in this the values of the compression module have a tendency to increase and to do so the laser power. Therefore, the polyamide sintered with a value of between 12 and 15 laser power W presents a greater rigidity showing a sintered with a lower power.

Figure 5. Variation of the voltage at the point of fluency in function

of the laser power.

of the laser power.

Related Companies or Entities

AIJU Instituto tecnológico de producto Infantil y ocio