TMC Cancels use NX and Teamcenter to answer with agility to the demand of the market

TMC Cancels is a company with headquarters in Galicia that devotes to the design and manufacture of agricultural and forestry machinery, like desbrozadoras and crushers. Founded in 1971, at present is one of the pioneers in Spain in his sector, with a growth of the turnover of the more than 20% annual. This company, characterised by his young staff, trusts the technologies

TMC Cancels increases of significant form the production

“Bet for offering a product of high value added based in the design, the quality and the research of the excellence”, explains J. David Señarís, responsible of Design of TMC Cancels. The company has a staff of fifty workers that soon will expand to give answer to the increasing demand of his products to international level. The products of TMC Cancels commercialise in almost all Europe, United States, Canada, Latin America and Africa. It foresees that in 2013 the exports suppose already near of 50% of the total turnover.

The excellent path of the company is due to his bet by a young and creative staff supported on the experience of the signature, his will to adapt continuously to the demands of the consumer and the bet by the investment in R&D, to which devote more than 12% of the turnover of the company.

“Design and develop we same, without externalizar at all during these phases. For us the technical department and of R&D is the brain and soul of the company”, affirms. In this sense, Señarís remarks the importance of the technologies of the information: “The communication between different departments, with providers and with customers as well as have of a good software for this is key to be productive and avoid dead times”.

Immediate advantages with the design 3D

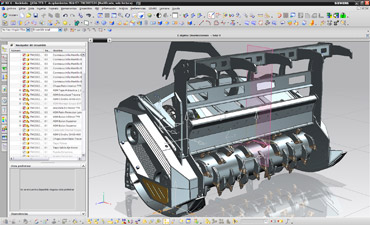

In 2010 TMC Cancels decided to implant a software of design CAD in three dimensions. “Until then we worked with a system 2D. To manufacture a prototype were months playing with staff, wasting material and with hours improductivas”, remembers Señarís.

After several months analysing the offer of tools CAD in 3D and collecting testimonies of users of several companies, TMC Cancels selected the solution NX of Siemens PLM Software: “it seemed Us that had a relation quality-price very good and liked us that it was a software highly configurable and modulate, something that would allow him grow together with the company”. Another reason for the election of NX was that his manufacturer, Siemens, is a company multinational of recognised prestige. “It offers you a big hygiene. You know that there is not danger that the software today exist and tomorrow disappear, that there is a technical backrest behind and that big companies of all the world also are betting by his technology”, ensures the manager of Design of TMC Cancels.

In only a week TMC Cancels implanted NX with the help and the learning of the professionals of Avantek, partner of Siemens PLM Software. In spite of have not worked never with a software in three dimensions, according to J. David Señarís the adaptation of the personnel was very fast thanks to the usability of the tool. On the other hand, the results did not take in arriving: “The change to work of two to three dimensions was drastic since we notice an improvement in the rapidity of answer, in the realisation of prototypes and in the management of the technical documentation. Say that it involved 100% in the productive improvement would be very little”.

Nicolás Pichel, responsible of Engineering of TMC Cancels, shares this opinion: “Thanks to the design 3D every time the prototypes go out more polishings, that is to say, seem much more to the definite machine that have in mind. The agility in the changes and in the design allows that we can launch more quantity of new products to the market and that the own company can be more flexible of face to the customer, so that if they request us a determinate model or a personalización have a capacity of reaction higher”.

Use of Teamcenter to increase the productivity

Satisfied with the performance of NX, TMC Cancels decided also in 2010 face a new project of improvement of his technological tools: implant a solution PLM. The implantation of Teamcenter lasted three months and included a review of several procedures of the company: “we do not pose us another software that Teamcenter of Siemens by his capacity of direct communication and in real time with NX and because had very good references of this system”, affirms Señarís. “We decide that Teamcenter was the starting point of the company, using his coding of items like only reference for all the processes and departments of the company. This has involved a very important improvement because have a greater order, organisation, flexibility and agility, without duplicities neither redundancies”, explains.

“Say that with the implementation of NX the production increased in 100% is very little”

Señarís Ensures that the decision to adjust his processes to the tool with personalizaciones punctual was key for the success of the project: “If a company falls in the temptation to want to adapt Teamcenter too much to his operation, runs the risk to fall in the same errors that already came committing. Instead, do a small effort to adapt to several points that the tool has predefinidos. In our case, this comported a big improvement of the productivity”.

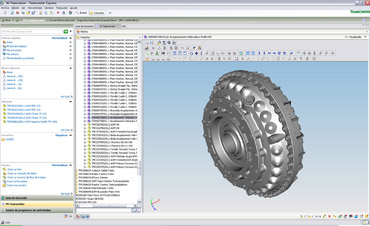

NX To increase the efficiency of the operations TMC Cancels uses five modules of NX –modelling, sheet, assemble, drawing and simulation- for the design, dimensionado, realisation of assemblings and the management of technical documentation, like manuals of setting and spare parts and the planes of manufacture. In this last appearance, J. David Señarís remarks that “in relation to another software of design, NX is very very attained to manage the manuals of spare parts, especially thanks to his perfect integration and synchronisation with Teamcenter”.

Regarding characteristics of NX, the manager of Design stands out the stability of the program, “that allows to work without unexpected errors”, and his big flexibility. “The management of the multiple levels in the assemblings is very easy because it only is necessary to cut and hit. The user can design the pieces to his rhythm without concerning by technical formalities neither have a structure preconcebida. Besides, it is very easy to use: the surroundings is very clean, intuitive and easily personalizable”. The stability, flexibility and usability of NX achieve a significant improvement of the efienciencia operative. The PLM like garante of the trazabilidad. The solution Teamcenter uses in TMC Cancels for the documentary management in the areas of design and put in production.

For Nicolás Pichel, responsible of Engineering, the PLM has today a very important paper in the company: “Have a rank of models very high, with a lot of variants inside each one of them. Can carry a system of documentary management for each model having a cycle of life of independent product gives us a very big agility for, for example, manage the spare parts and the performances postventa”.

Nicolás Pichel stands out of Teamcenter the rapidity with which can access to the information of any piece/ item in relation to the design, the put in production, the changes or the validations. In this way, the trazabilidad of the information is guaranteeed, a key appearance also for the controls of quality. Besides, it says, it is very easy to realizar researches to access to any piece thanks to the big quantity of filters personalizables that it has.

Another appearance to underline, as it explains Nicolás Pichel, is the flexibility of Teamcenter in relation to the process of saved and of change of name or description: “When we split of an already existent design to realizar another, Teamcenter gives us an a lot of flexibility to do changes, reviews and saved of assemblings and pieces, without having problems of bonds and with a big ease to handle groups so much big like small”.

Finally, the manager of Engineering of TMC Cancels stands out the usability of the tool, with some “very simple surroundings to use”.

Arrive to the market with greater rapidity

Three years after implanting the technology of Siemens PLM Software, TMC Cancels values very positively the results. By this reason, the company plans in the next months migrate NX and Teamcenter to the last versions and purchase new licences. Other projects that have foreseen are the connection of Teamcenter with his ERP and expand the use of this solution to the departments of shopping, production and post-sale.

“Nowadays launch a new product before that your competitors is paramount since probably also they will have detected the same needs in the market. By this is necessary to speed up to the maximum the times of development, something that allow us the solutions of Siemens PLM Software”, says J. David Señarís.