Implementation of CAM compatible with machines multifunción

Aurea López, director of Marketing Spain and Portugal of Siemens Industry Software S.L.

05/12/2013The need to speed up the process of programming, combined with the wish of a better quality of the mechanised and of the superficial finishing has carried to the company Essil — specialised in the manufacture of mechanical boards and complementary systems of boards instrumented with diverse machines CNC of turning/milling of 3, 4 and 5 axles— to the development of a solution CAM.

Eagle Seals & Systems India Ltd. (Essil) Is a subsidiary participated to 100% by Eagle Industry Co. Ltd., part of the Japanese company NOK Corporation. The company manufactures mechanical boards and complementary systems of boards for sectors like the chemist, the petrochemical, of fertilizantes and chemist. Essil Began to manufacture mechanical boards in 1975. Since it has turned into the main Indian manufacturer of these products, backed by a national network of sales and technical assistance, two factories and a centre of R&D entirely instrumented. Essil Has a wide wallet of customers that includes local and foreign organisations of the public and private sectors.

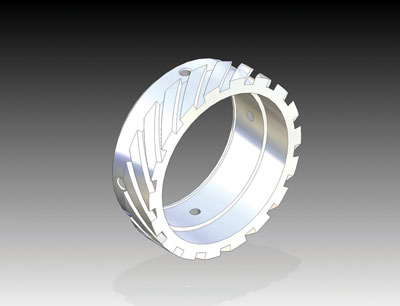

Essil Manufactures mechanical boards and systems of hermetización.

Essil Manufactures mechanical boards and systems of hermetización

The line of products of Essil includes boards of bellows, mechanised and of push. The assortment of the boards of bellows is very wide: only with metallic bellows there is more than 15 models. They use materials like alloys of steel, titanium, neoprene and PTFE (politetrafluoroetileno). More than 25 years of experience in the treatment of fluids to high temperatures have converted to the boards of metallic bellows of ESSIL in an usual component of refineries and petrochemical applications. The boards mechanised design to satisfy the increasing demand of resistant boards for applications in which the speeds surpass the 10.000 rpm, the pressesures are greater that 100 kg/cmP and the temperatures are inferior to the 200 °C or upper to the 600 °C. Essil Has the widest assortment of boards of push, with more than 20 varieties of models of several docks and 8 of an alone dock, including bisteeringal options.

“Expect recortar costs between a 10 and 15%. This is not only consequence of the increase of the productivity if no also of the reduction of the wastes and repetition of works”

Need of CAM

Essil Has diverse machines CNC of turning/milling of 3, 4 and 5 axles. These machines were programmed manually during 15 years. But the need to speed up the process of programming, combined with the wish of a better quality of the mechanised and of the superficial finishing, convinced to the company that it had arrived the moment to update to a solution CAM. In his research of software CAM, Essil evaluated originally six distinct programs, but any had a postprocesador able to generate code for the machine Mazak Integrex of the company, a combination of centre of turning and centre of milling.

In a determinate moment, Essil put in contact with Gnosis InfoTech P Ltd., a distributor of value added of products of Siemens PLM Software. A representative of Gnosis showed the functionality of the solution CAM Expresses of Siemens, as well as his compatibility with the software CAD of Essil, Solid Edge, also of Siemens. In the demonstration could appreciate clearly the advantages of CAM Expresses in comparison with other programs of software CAM. “Between this and the backrest that Gnosis could loan us in matter of learning and development of postprocesador, opt for implementing CAM Expresses”, remembers P. N. Mehta, general director of Manufacture in Essil.

Implementation of CAM

Gnosis Commissioned of the qualification, that began by the most basic until reaching a level advanced. The distributor also developed a postprocesador with the help of Tata Quality consultancy Services, that allows to Essil take out the maximum split to his machine Mazak Integrex. With this backrest, all the machines reached perfect provision. Since, Essil has come harvesting the profits of the solution Solid Edge/CAM Expresses.

For example, the company has foreseen to reduce the time of programming of machines between a 15 and 25%, thanks to the increase of the productivity of the programmers. “And also we expect recortar costs between a 10 and 15%”, adds Mehta. “This no only is consequence of the increase of the productivity but also of the reduction of the wastes and repetition of works”. On the other hand, the company has fulfilled his aim to perfect the quality of the mechanisation and the superficial finishing. These results have convinced to Essil of the value that contributes this solution of Siemens. “Taking into account our future requirements, have decided to standardise us with CAM Expresses”, concludes Mehta.

Business initiatives

- Develop of new products

Challenges of business

- Agilización Of the programming of the machine-tool

- Improvement of the quality of mechanised

- Reduction of wastes

Keys for the success

- Solutions CAD and CAM perfectly integrated

- Compatibility of postprocesamiento for all the machines, including the centre of turning and milling Mazak

Resulted

- Planned reduction of costs of 10 to 15%

- Forecast of saving of time between a 15 and 25%

- Increase of the productivity

- Less puezas refused