DMG Mori Gathers again to the sector of the mechanised

After his go through the EMO of Hannover, where

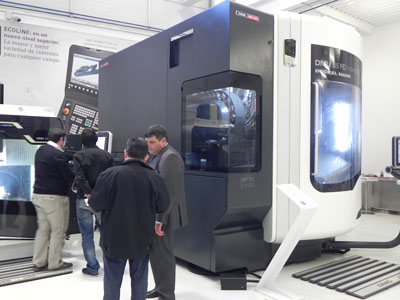

A total of 178 companies of company of mechanised happened of the 13 to 16 November by the installations that DMG Mori has in his installations of Barcelona (in the polygon of Can Salvaterra, in Ripollet) in the last edition of the year of his days of open doors. In this occasion the signature organised also the day 13, together with his collaborator Sandvik, a demonstration of taladrado and threaded.

Along the 4 days of days of doors opened the visitors could see at first hand a selection of technologies of milling and turning “with the best conditions of purchase and availability to the instant”. In the centre of technology of the signature showed in direct the mechanised by start of shaving with the series Ecoline, the mechanised of milling and efficient turning with the DMU 85 FD monoBLOCK and the high stability and precision with the series NLX 2500, among others.

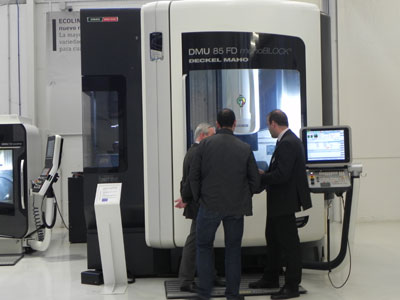

DMU 85 FD, technology of milling and turning for the mechanised complete

One of the exposed models and that attracted greater attention by part of the assistants was the DMU 85 FD, a machine that allows to realizar the mechanised complete in an alone unit, being able to mill and tornear on the same subjection, what reduces the level of investment required and the necessary space to work. Besides, this model includes table of milling and turning with technology Direct Drive for maximum 1.200 rpm and maximum dimensions of the piece, 850 x 590 mm, and weight of the maximum piece 1.000 kg. Endowed of rotary presses table bsculante, also in version Tandem Drive with accionamiento bilateral for even more stability and dynamic, incorporates a powerful engine husillo of 18.000 rpm with 35 kW and HSK-To63 in the package of milling and turning.

On the other hand, the cycles of milling and turning of the DMU 85 FD cuemple with all the requirements of the manufacturer as they are determination, control and supervision of the disequilibrium; adjust automatic of the number of revolutions because of the vibrations of the piece; cycles of measurement for the sensor of longitudinal measurement: calibration of the sensor of measurement in the area of mechanised, measurement of tronzadas, slots, etc.; memorisation, edition and transmission of the data of measurement; turning with axis To accionado; and orientation of long tools to the interior of the piece.

Includes besides the cycles of milling and standard turning like tronzar, destalonar, cut shavings, roscar, etc.; application of tools of multiple sharp edges (maximum nueve); and measurement of tools to mill and tornear.

DMG Mori Celebrates periodically these events inside his strategy of company to be presents in the diary of his customers, although in years like the next 2014, coicidiendo with the BIEMH, will limit the organisation of these days.

On the other hand, and taking advantage of the closing of this exercise, David Gatell, general director of DMG Mori Iberian, commented us the positive balance that the signature does of 2013: “the result of this year is very positive thank you mainly to sectors like aeronautical sector component manufacturing sector component manufacturing and mould”, admitting that “the companies that at present want to invest pricipalmente are those that export”.

Likewise, explained us the new nomenclature of the company, that becomes DMG Mori —instead of DMG Mori Seiki—: “This decision is resulted of the consolidation of the mark what supposes on our part a very positive assessment”.

Regarding the past edition of the EMO in Hannover, Gatell adds to the positive feelings that generated the fair between the display units: “This year it has been the EMO more important of the history of our group, so much to level of image as of results” to add that, in 2014, foresees that it was “surely the BIEMH more important in a lot of years”, showing his confidence in the Biscayan announcement.