New geometries of

It reaches the step to Tiger•tec Silver

Speed, hygiene and long life of tool. These are the three big advantages of the material of cut of high performance Tiger•tec Silver for the mechanised of foundries, which now are available in two new rompevirutas: a rompevirutas smooth with a small stair, as well as an especially robust variant for a maximum hygiene of process, even for cuttings interrupted extremes. Besides, Tiger•tec Silver already is available with the rompevirutas universal MK5 from June.

A key and main characteristic of the new rompevirutas for material ISO K is the small existent stair between the edge of cutting and the surface of support of the plate. This stair allows the rectified of the faces of support after the coating. This is not possible in the standard geometries CNMA, DNMA… Since they do not have any slot. Whereas a surface of irregular support can drive to micro-vibrations and to micro-fissures in the edge of cut, the uniformity of the face of support of the new geometries ISO K of Walter ensures that the negative plate of double expensive is settled with the maximum stability. Like result, the wear of the edge of cutting reduces , in particular in the cases with high dynamic loads.

Special design for mechanised of foundries

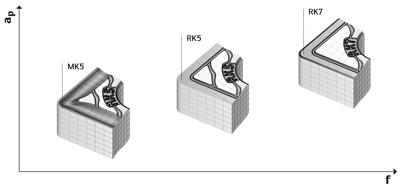

The rompevirutas MK5, RK5 and RK7 –universal, classical and robust– were especially designed for the mechanised of foundries. The rompevirutas MK5 for ISO K is for mechanised means and is adapted for all type of pieces of smelting. Has a rompevirutas with open slots for a soft cut and would have to be used, especially, for foundries nodulares (GJS), unstable pieces and mechanised interns by his low strengths of cutting.

The rompevirutas RK5 and RK7 are new for applications of desbaste. RK5 is the rompevirutas classical plane without slots for the mechanised of foundries, his stair in the face of support guarantees the hygiene of process. The surface of support rectified in plates type CNMA, DNMA… Ensures a big life of tool and the maximum hygiene of process, for example, in the cases of big dynamic loads and of cuttings interrupted. RK5 is the first option in the mechanised of grey foundries. RK7 is an extremely robust geometry for severe discontinuous cuttings, variations of tolerances, big variations of past and mechanised of cascarillas of foundries. The rompevirutas is similar to the RK5, but also has a chamfer of protection in the edge of cutting. Also it is adapted for the mechanised hard/soft in steels toughened from 40 to 61 HRC, in those cases where the plates of CBN are not adapted.

Speed, hygiene and a big life of tool

The material of cut Tiger•tec Silver offers to the customers of Walter three main advantages: speed, hygiene and a big life of tool. The increase in the speed of cut is resulted of the coatings Tiger•tec Silver CVDs with oxide of aluminium and a micro-structure optimised. Thanks to the alignment optimised of the structure, needs more time of contact for the wear by craterización, that alters perjudicialmente the geometry of the edge of cutting. A mechanised faster and flexible is the result.

An increase in the reliability of process and in the tenacity –is the second big advantage– is reached thanks to the post-mechanical treatment. Doing this, tensions of compressesion are entered in the coating, which warn the fracture of the edge of cutting. Like result, this material of cut can be entered in the productions in series without any problem, and without giving place to breaks or deviations.

The third important characteristic of the coatings Tiger•tec Silver is the increase of performance by a long life of tool, in particular when mechanised pieces of smelting. Can increase until 75% the life of the tool in individual cases and also can increase the performance.

Tiger•tec Silver WKK10S and WKK20S

The degrees Tiger•tec Silver WKK10S and WKK20S are adapted for grey foundries (GJL), nodulares (GJS) and vermiculares (GJV). WKK10S is the hardest degree and stands out by his big Resistance to the wear with high speeds of cutting. His main utilisation is for grey foundries with continuous and light cuttings discontinuous. WKK10S is particularly adapted for the mechanised in dry. In contrast, WKK20S is adapted for the mechanised in dry and humid. Like material of universal cutting, WKK20S is adapted for 50% of the applications, and offers a high reliability of process and special for pieces with cuttings interrupted, with cascarilla or with holes crossed. The ductile foundries are the main application of this material of cutting.

The proofs of field that have carried out, between others, in brakes of disk (GJL250 material) and in crankshafts (GJS600 material) in the installations of a provider of the industry of the automotive sector, gave like result an increase between the 50 and 100% in the life of the tool. The plates worked so much in mechanised external and internal, and stood out especially by the hygiene of process, especially in the mechanised humid of the crankshaft.