Hypermaxx, now also available for mechanised 2D

From 2011,

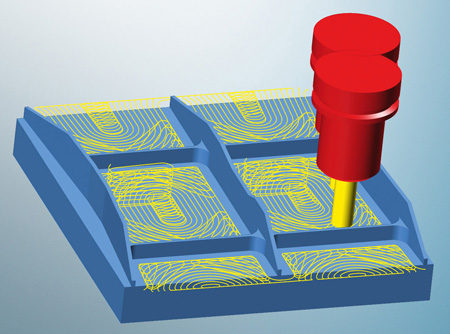

Hypermaxx, the complete module of desbaste integrated in Hypermill, offers some paths of milling optimum, a maximum withdrawal of material and some times of minimum manufacture. The ideal distribution of the paths of milling and the adjust dynamic of the advance to the conditions of existent cutting achieve that the milling effect always to the maximum speed of advance.

The mechanised carries out exclusively in milling trepado, with shrinkings in spiral of the paths of the tools, that at the end approximate always more to the outline wished. The tool of milling works usually with the length of complete cutting and the system has a special algorithm that commissions that always it withdraw the same volume by tooth of milling. Of this form, the tool can use to full performance without arriving to overload it and produces a big total volume of shaving by unit of time.

The condition for a mechanised optimum roots in the dynamic adaptation of the advance to the conditions of existent cutting. Like this, the user does not have to enter any fixed value of revolutions neither advance, but data of reference that so much the tool like the corresponding machine tool can apply. The path of tool of Hypermaxx calculates taking into account the volume of shaving and a harmonic distance. Of this form, the method results adapted so much for soft materials, like the aluminium, as for others harder, like the steel, the titanium and the alloys of nickel.

Main advantages of Hypermaxx

- Tool and machine bear uniform efforts during all the mechanised

- Time reduced of operation of the machine

- fast Positioning and sure of the tool

- The macro of entrance generates always a helicoidal or staggered movement complete: it is not necessary to indicate a radius propeller, since it calculates automatically

- do not produce sharp edges or sudden changes in the steering of milling

- intelligent Automatisms for the adaptation optimised of the advance and the past during the mechanised of narrow zones with complete cut and paths of long tool (soft material), as well as of paths trocoidales to avoid the complete cut (material harder)

- Can penetrate with the 100 % of the diameter of the tool without that the material detain

- The process to protect the tools generates another positive effect: the users can access with frequency to other qualities of milling simpler with costs much more reduced

- is not necessary to realizar an adaptation of the postprocesadores, since Hypermaxx is entirely integrated in Hypermill.

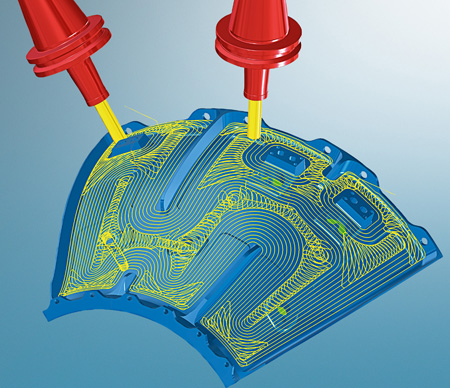

Enlargement for the mechanised 2D and of 5 axles

Hypermaxx Will be able to use also in mechanised 3D for any outline of piece in the rough, as well as in the desbaste equidistant of pieces of 5 axles. Open Mind Offers this strategy of optimisation for the cut of high performance and for the milling of cashiers 2D.

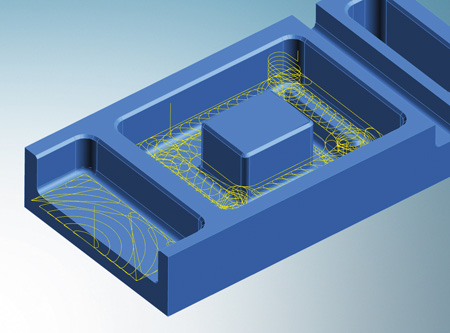

In the milling of cashiers 3D is possible to mechanise to a notably greater speed any cashier, already was open or enclosed, cashiers with islands, etc., with help of Hypermaxx.

Hypermill 2011 entered the desbaste and equidistant finishing of 5 axles. In this process, the surfaces curves of a component, as for example, the carcasa of a turbine, the structural pieces of the aeroplanes or the moulds of tyres, take like normal surfaces. In this case, the tool works in each point with an angle of 90 degrees. This strategy works therefore as if it treated of a desbaste or finishing in Z ‘flexionado'. This procedure facilitates enormously the creation of the program of CN.