Life longer and safe processes in the ranurado and tronzado

The new coatings and rompevirutas are allanando the way to reach maximum performances, previously inalcanzables, in the ranurado and the tronzado. His properties combine a high level of tenacity and of resistance to the wear, something that is extremely advantageous in operations of tronzado.

Ranurado And tronzado are two types of operations of turning that have only demands in the tools like result of the conditions of the mechanised. Although Walter AG carries some seriously involved years in this area, the company has been able to use his experience in the field of development of material of cut to integrate his innovative strength without problems in other respects of the tools of hard metal.

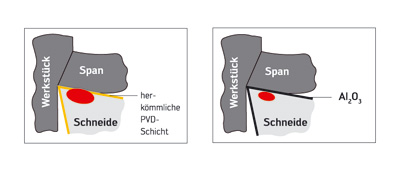

The result of the work with recent successes of development is a new family in the ranurado and tronzado with geometries especially developed for the tools of hard metal. Here the sustrato and the coating produce a quality of hard metal. “Through a greater development, Walter has attained an additional increase in the resistance to the wear by temperature with the degrees PVD with oxide of aluminium without engaging the tenacity of the material of cut”, explains Gerd Kussmaul, responsible senior of Turning Walter AG. The hardness of the new oxide of aluminium is greater to the one of his predecessor, that marks a significant improvement in the behaviour of wear. The friction in the face of detachment is lower thanks to an optimised structure of the surface, that to his time means a lower temperature of friction.

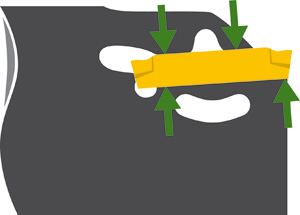

Lick it of tronzado deep G1042, the system of autoamarre elastic of 4 points, ensures the best seat of the plates type GX.

The degrees of Walter Tiger•tec Silver PVD have tested that the resistance to the wear and the tenacity are not in contradiction. The layers of To the2Or3 work like a shield of protection in front of the heat and characterises by a thermal sensors load drop for the sustrato of micrograno. The flow of entrance of heat is also lower that in the comparable products like result of the layers of To the2Or3. The layer plateada does easier the detection of the edges used and of the no used. This ensures that all the edges of cutting use of optimum form. The sustrato of the microgramo produces an extreme quality of the edges of cutting. The high precision of the geometry of cut guarantees us a life of constant tool. The low thickness of the coating PVD allows to reach some edges of cutting very sharp. “The decisive advantage in the practical is the result of a life of tool extremely consistent”, says Gerd Kussmaul.

The rompevirutas CF5 with coatings PVD Tiger•tec Silver: the combination of big hardness and tenacity are not in contradiction.

Edges of sharp and clear-cut cut

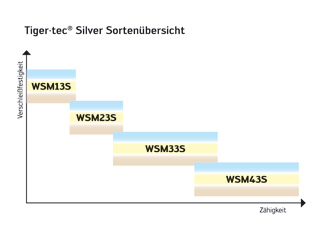

The quartet formed by four qualities of hard metal for operations of ranurado and tronzado form the future range of coatings PVD with oxide of aluminium. The designations are WSM13S, WSM23S, WSM33S and WSM43S. They are universal degrees with areas of application in material ISO-P, ISO-M and ISO-S. Like result of his hardness, the degrees WSM13S and WSM23S are adapted for conditions of stable cutting, and particularly adapted for material ISO-S. The degree WSM33S is of universal use for 50% of the applications and for the users that have big variety of materials. The WSM43S is the first option when the conditions of cut are unstable, low speeds of cut, tronzados until the centre or cuttings interrupted thanks to his excellent tenacity. This means that there is available an optimum degree for any application.

When it uses the connection between the new geometries of cutting and the four degrees offers a very high performance and life of tool, and a big reliability of the processes of ranurado. Particularly, the edges of sharp cut can reach by the low thickness of the coatings Tiger•tec Silver PVD.

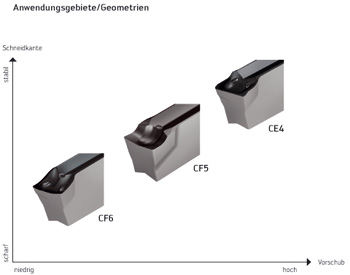

The geometries that guarantee the maximum precision

The stood out performance of the plates Walter Cut is hit by the combination of the degrees of cutting and the rompevirutas CF6, CF5 and CE4, this last especially adapted for the tronzado. The rompevirutas CF6 —‘the sharp'— characterises for generating the minimum rababa and tetón, and is particularly adapted for small diameters and for the tronzado of tubes of little thickness. The rompevirutas CF5 —‘the positive'— also produces little rebaba and tetón, covers the widest area of start of shaving and recommends like the first option in the applications of tronzado. The rompevirutas CE4 —‘the stable'— has an edge of cut protected that controls perfectly the shaving. All the rompevirutas also are available in plates anguladas of rights and of lefts with angles of 6, 7 and 15°.

Only lick with elastic fixation of 4 points

Depending of the type of adapter of the machine, the users require a different rank of tools. “It is in this field where the new system Walter Cut GX is leading the way of the operations of tronzado”. During the the operations of tronzado, does a distinction between the small (until diameters of 12 mm), average (until 40 mm of diameter) and big (diameters until 110 mm). The range composes of four innovative tools never before seen.

Lick it of tronzado deep G1042 has a seat of plate with 4 points of support. “The principle of fixation of 4 points does not have precedents when it treats of lick and generates a level of greater stability”, explains Gerd Kussmaul. The system of autoamarre is simple of use. It lick it of tronzado reinforced G1041 has the same system but with fixation by screw, is available in right hand-held version, left and even in versions against.

The tool holders monobloque G1011 is adapted for the tronzado, the ranurado and the turning. Has a head of fixation by small screw to favour the flow of the shaving out of the slot and the grub screw of the plate is accessible by the top and inferior of the tool holders. The new tool holders monobloque XLDE provides an easy access to the grub screw of the plate, is available in versions to the against and is ideal for the manufacture of small pieces in the industry of the bar-cutting. “The primary use of the tool holders monobloque XLDE is in lathes multihusillos and in lathes Swiss types since there is not a lot of space in the zone of mechanised”, explains Gerd Kussmaul. “The screw of tie up is bent and facilitates the change of the plate without having to soltar the tool holders of the machine. This helps particularly to increase the productivity”.

The system Walter Cut GX was essentially developed for the ranurado, tronzado and turning for all the types of lathes. A depth of work of 23 mm during the process of ranurado and a tronzado of until 46 mm can reach with plates of double tip. Ranurados And tronzados to a depth of considerable work can reach with the same tool holders with plates of an alone edge of cutting.

“The main advantage of the new technology for the ranurado and the tronzado is the fact that it is a system of ranurado for all the applications of ranurado and all the tools are valid and standard for the tronzado and the ranurado ”, says Gerd Kussmaul, resumiendo the system Walter Cut GX.

The high level of performance when using the new tools of ranurado can show with the example of tronzado of the track of the rolling of balls of material 100Cr6 (1.3505). “Here we are using the plate GX16-1And200N020-CE4 WSM33S — Walter Tiger•tec Silver— to reach a life of 950 pieces, that is 111% elder that what can offer the competition”, account Gerd Kussmaul. “As such, the mechanised with the product of Walter characterises by a life of tool more consistent, an improvement in the planitud of both expensive tronzadas and an excellent control of shaving”. The tool holders monobloque G1011 is used in this application. The whole system (tool, degree and geometry) guarantees the maximum hygiene of process. “It is an only development of the complete system of tool, that is to say, tool holders, geometries and materials of cut, that distinguishes us of the rest of competitors of the market”.

Tronzado Of bars

Is essential the annotation that in the operations of tronzado the tool holders has to to be the most rigid possible. The section trasversal of the cuadradillo has to be the greater possible whereas the voladizo of the tool the lower possible. This warns the vibrations that have a negative impact in the quality of the piece and in the life of the tool. For save material, the width of tronzado has to to be the lower possible. This also minimises the strengths of cutting. Depending of the type of tool, the ratio between the width of the plate and the diameter to tronzar does not have to exceed of 1/8, for example, in the case of a plate of width 2 mm, the maximum diameter that would have to tronzar would be 32 mm. The operation of tronzado has to do the more near possible of the pinza of tie up of the bar to warn unnecessary and hurtful vibrations for the application and for the tool.

A particular challenge that affects to the tools of tronzado is that when it is reached the maximum turns of the machine, the speed of cut diminishes until arriving to zero in the centre of the piece. Likewise, the lubrication in the zone of work is very complicated when the tool does slots or tronzados deep, what means high thermal sensors and mechanical loads. It is recommended that so much the tool like the portaherramienta are face down, so that when the piece was tronzada do not strike the others edges of cut of the plates and to favour the evacuation of the shaving by gravity, like this will obtain a life of stable tool.

Where was possible, the utilisation of plates of tronzado neutral will be the best option. The use of the plates anguladas of rights or of lefts avoids rebabas or tetones, but at the same time have a negative effect in the superficial quality obtained, in the planitud, the efforts generated are greater and the life of the tool is lower. This utilisation also has a negative effect in the forming of the shaving. To reach rebabas and tetones minimum, is possible to mechanise with plates without radii in the corners of the edges of cutting.