The new tools of

Reduction of the time of cut in grey smelting

Falk & Webs Bearbeitungstechnik GmbH & Co. KG, Villingen-Schwenningen (Germany), established in June of 1999 by Josef Webs, Industrial Mechanic, and Klaus Falk, Industrial Supervisor and Technical Administrator of Companies, like provider of several companies in machines and installations of engineering. In 2001 Falk & Webs assumed the production of components of a company in failure that operated in the machinery of special use and area of engineering of the plant. Falk & Webs purchased the 14 employees, increased the zone of production of 160 to more than 2.000 m² and the enlargement of his range of products, Falk & Webs now has 25 employees. The base of customers covers from components of steel for the industry of machines of packaging and machinery of special use for the alimentary industry.

But the manufacture of pieces for equipment of the industry of panificación requires of time of mechanised critics. And operations like taladrado and milling in pieces of grey smelting have improved of significant way by the change in the plaquitas of taladrado and milling manufactured by Walter AG in Tübingen.

Klaus Falk, general director and owner of Falk & Webs, explains: “Under the lemma ‘one for all, all for one' can produce something for each need of mechanical engineering from individual components with a diameter of 5 mm, of complete systems for the industry of the steel or the industry of equipment of bakery, as well as the distinct pieces and batches extremely small of any type”. And it adds that “around 30% of our traditional customers proceed of the industry of the panificación”. The competition by the quota of market is very intense in this zone. At the beginning of 2012 a known customer gave to the provider of mechanised the task to produce a carcasa of agitador special. It treats of a carcasa done of grey smelting (GG25) in which it mounts the box of changes or the engine of accionamiento. “However the requirement does not limit only to the application to machine but it also participates to complete all the production inside a window of time reduced of significant way and with an inferior budget to the one of comparable work”, explains Marcel Golec, manager of production of Falk & Webs.

“Our customers also have to face up to the pressesure of the competition in his industries, and afterwards happen these challenges to us”, stands out Marcel Golec. “To keep on being competitive, find us with the challenge to treat to improve even more our processes”. The equipment of Falk & Webs have been working in the optimisation of his processes during long, but this time demanded even better tools with an useful life longer of his main provider Walter. “We think that the work of mechanised still was taking too time using the tools Walter existent in this project, by what our price is too expensive for our customers”, stands out the manager of production.

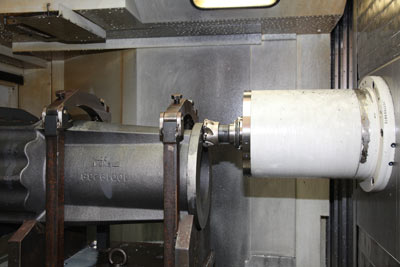

Regarding the mechanised of the carcasa of gear of the agitador, the challenge was mainly a case of optimisation of the operations of taladrado and milling. The aim was to save a significant quantity of time during the mechanised global. The situation in situ shows a centre of mechanised in which several components can mechanise simultaneously. With the end to improve the time of cycle here, the engineer of application of Walter Juri Gaymann and his colleague, the commercial technician Reinhard Schwendemann, collaborated with Marcel Golec to tackle the task of control of the requirements in the place and in search of improvements. "On the base of the manufacturing of components of the customer and the requirements in situ in Falk & Webs, then develop a concept of mechanised, look the last variants of tools and recommended us parameters of mechanised suitable ", says Reinhard Schwendemann on the services loaned by Walter to his customer.

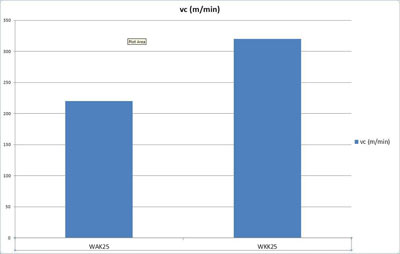

Parametros Possible explored in depth in situ

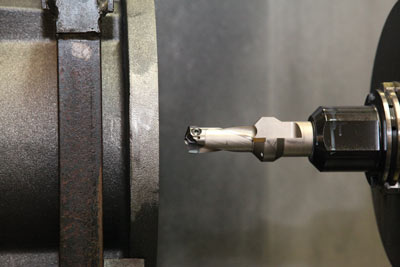

The clear-cut parameters were reviewed in situ in Villingen-Schwenningen. They used several plaquitas interchangeable of taladrado and milling of new range of products of Walter 2012. The tools and plaquitas interchangeable that chose were analysed and the possibilities exhausted with different combinations and parameters. Finally, the life of the tool increased of significant way by means of speeds of cutting and advance faster. The new tools, modified with different values, were crucial here: Walter Xtra - tec -F4080 with plaquita octogonal of eight edges of cutting and the plaquita of taladrado P6003 for the Xtra - tec -Point Drill B4215, broca of tip of hard metal for a depth of taladrado of 5xd, that now uses for the mechanised of the gear of the agitador done from material GG 25. The quality WKK 25 was chosen for the plaquitas of cutting the plaquitas interchangeable. This made possible a life of the tool significantly longer and a speed of cutting faster.

Optimisation of innovative processes

“Never had attained this type of optimisation of innovative processes without the extraordinary commitment of the employees of Walter”, stands out Marcel Golec. “Never we could have attained this with the previous tools. The new tools that also could test in situ have given us a lot of more options that before”, explains the boss of production.

“The time of mechanised by piece has reduced to the half. This applies so much to the taladrado as to the milling. The plaquita of taladrado P6003 can use of universal form, with meyores speeds of cutting and of advance and attains resulted significantly better”, explains Marcel Golec. This also applies to the new plaquitas of milling, that are used exclusively by Walter.