The toy sector and furniture auxiliary contributes to their sustainable materbaches applications.

New environmentally friendly masterbatches with the environment based on almond shells

It embodies German Baeza, Asunción Martínez (Aiju)

08/07/2013A concentrate or 'masterbatch' consists of a polymer matrix in which integrates a high proportion (50-80%) of pigments, dyes, waxes in dispersion, fillers and other additives. These masterbatches, in the form of pellets, are added to the polymer, in the form of pellets, during the transformation process (injection, extrusion, etc.), resulting in a method of economical and simple additive for plastics processors.

Identified major trends of plastics processors include willingness to integrate new sustainable, high-performance, cost-effective products in the market. For this reason, masterbatches developed in this proposal perfectly meet these three factors because there is currently no type of masterbatch for polymer products by injection that incorporates natural waste or, in particular, almond, as load or reinforced shell. Hence the main need for the development of these products.

The introduction of these masterbatches in traditional sectors such as the toy and furniture, gives significant support to their sustainability in the medium term. Additionally, it addresses the environmental problem related to the improvement in the efficiency of use of natural resources through the reuse of the almond shells, since natural fibers do not require exogenous input of energy (contributing to the improvement of the environmental performance of the consumer products and intermediates).

| The objective of this project is to develop new color concentrates, based on natural waste arising from agriculture (almond shell) with various thermoplastics, both conventional and biodegradable. |

The products developed within the project are based on novel formulations of thermoplastic colored loaded with almond shells, obtained in a concentrated way, adding in the process of injection plastic matrix of the same nature that has been formulated masterbatch.

The technical tasks performed to date have been:

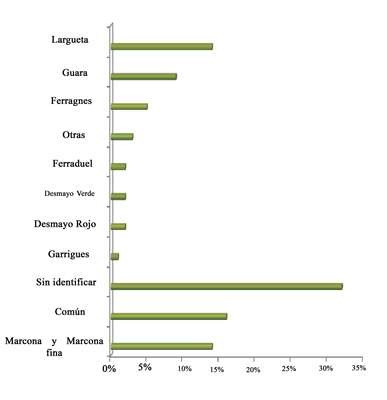

Study of the incorporation of the shell of almond in thermoplastic matrices. For this reason, done a previous study of the State of the art concerning the almond shells as to varieties of shell, suppliers, properties and possible treatments required for this natural waste processing. Additionally done a search of the State of the art on the compatibility between the polymer matrices and natural waste and different specific methodologies so far to overcome the possible incompatibilities. It has conducted a study of the State of the art on additives, fillers and pigments that are more compatible with natural fibers and matrices employed.

In addition we have studied different matrixes thermoplastic, choosing is polypropylene, polyethylene and TPU, polymer widely used in auxiliary and footwear, toy, furniture sector with charges and appropriate additives being. Therefore, the different types of existing polymers for use in the intended applications are rated: chemical composition, shape of supply (powder, granules), prices, physico-chemical properties, etc. All this has enabled us to have a previous knowledge to begin the development of masterbatches and final demonstrators, during 2013 with and without colour for its subsequent injection and characterization.

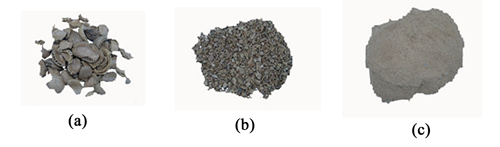

Figure 1. Shell almond "Common" with different particle sizes. (a) almond shell supplied into pieces, (b) almond shell with a particle size of 0.5 mm and (c) almond shell with a particle size of 0.08 mm.

Once defined the specifications and having prior knowledge the following technical tasks are carried out in 2013:

- Formulation and preparation of different batches of masterbatches (Figure 3) percentages of almond, particle, typology of shell of market sizes, shell mesh, pigments and other additives that require formulations, to optimize formulations with best behavior when it comes to its use with all agents modifying.

- Incorporation of masterbatches to the polymer matrix, to optimize injection processes, see Figure 3.

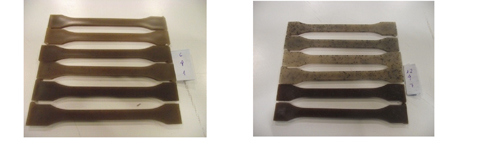

Figure 4: Injection of specimens of polymer matrix of the different percentages of masterbatch integrated polypropylene.

- Mechanical characterization of extruded masterbatches, as well as of the compose injected.

- The first pieces of toy development, see Figure 4, developed with masterbatch as well as the seat of a Chair, in the furniture sector.

- Addition of pigments to the masterbarches for subsequent processing of injection in the final demonstration.

This year it is expected to develop new demonstrators, as well as to solve problems encountered during the injection of polymeric parts on an industrial scale, the addition of pigments to the own masterbatch, thus manufacturers of auxiliary toy and furniture sector can have an economical, easy and reproducible means of additive parts.

Figure 5: Example of demonstrator to carry out injection of parts with masterbatch. Development of front wheel covers injected with masterbatch of polymer matrix of polypropylene with different percentages of shell almonds and colouring.