Essays of fatigue based in real situations of operation of piece

The Foundation CTM Centre Tecnològic has of equipment of fatigue servo hydraulics and of resonance to evaluate the behaviour to fatigue in all the ranks of cycles, from 103 - 104 until 107-108. In the last years, thanks to the bet by the technological innovation realised by the centre and the continuous acquisition of new equipment is possible to realise essays of fatigue in the rank of temperatures comprised between -130 and 1.000°C and in several means (fatigue-corrosion).

The behaviour to fatigue of a determinate component is his capacity to resist to the deterioration in the transcurso of a series of efforts. Can distinguish three behaviours to fatigue differentiated:

- If the loads are elevated, next or upper to the elastic limit, the material bears a number reduced of cycles before the fracture, between 103 and 104, what knows as to fatigue oligocíclica or LCF (‘low cycle fatigue').

- If the loads are lower, the life to fatigue increases, around 106-107, rank known HCF (‘high cycle fatigue). The level of load that produces fracture in this rank designates limit of fatigue.

- To inferior loads to the limit of fatigue do not expect fracture of the component and the life of the component can consider infinite. However, recently it has ascertained that in materials of high mechanical resistance from 107-108 cycles produce breaks underneath of the limit of fatigue. This rank designates VHCF (‘very high cycle fatigue').

The limit of fatigue defines typically for the majority of metallic materials applied in engineering between 2 106 and 107 cycles. The greater part of the designs of components with structural responsibility situate in this last stage, in which it considers life to infinite fatigue. From a theoretical punto, are three the most used approximations for the design to fatigue:

- Approximation based in tensions/load, where determines the limit of fatigue of the material from essays in which it fixes the amplitude of the tension/loads.

- Approximation based in deformations, in which it fixes the amplitude of the deformation.

- Application of concepts of mechanics of the fracture, especially when the component presents cracks or initial defects.

The type of essay to realise and the theoretical approximation to analyse the behaviour of a component depend on his requests of operation (loads and deformations applied and geometry and disposal of the component in the application).

From the Fundació CTM Centre Tecnològic leads all the process of identification of these requests, design of useful, tuned of the essay of fatigue and analysis of the final results, providing soluciones.de material and design if it proceeds.

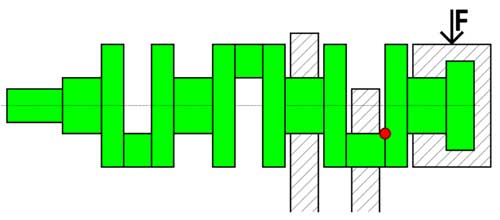

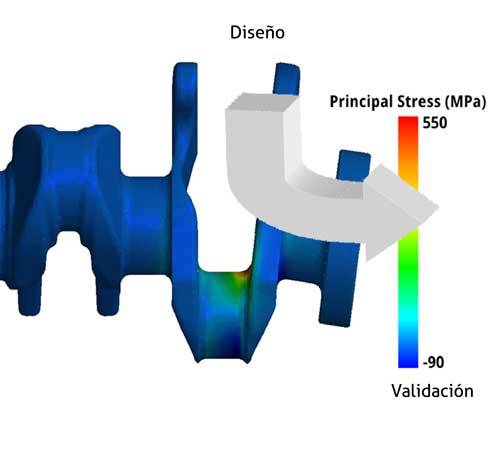

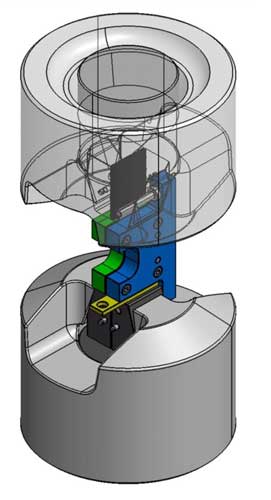

The first stage consists in the design of the tooling that has to transmit the efforts or deformations to the material or component. In this point is vital the suitable design of the toolings, so that the essay reproduce faithfully the situation of the component in service. It uses simulation by finite elements to design the useful and validate the essay. Once validated the tooling proceeds to his construction in collaboration with external workshops.

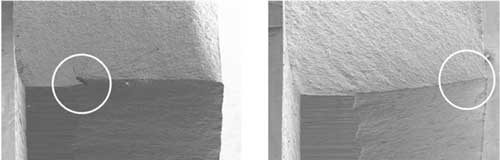

In the last years the technical personnel of the Fundació CTM Centre Tecnològic has specialised in specific essays for sheet of steel of high resistance, especially used in the sector automotive sector to reduce weight and increase resistance to impact. Fruit of this experience, Fundació CTM Centre Tecnològic has developed specific toolings for the essay of sheets of thickness reduced like toolings anti-pandeo or for the realisation of essays of flexión of sheet “plate bending”.

In those cases that was necessary to llevar essays to high temperature, above 400°C, the centre has of the knowledges and technology for the design, validation and construction of toolings refrigerated.

Once finalised the validation of the essay, are the technicians of the Fundació CTM Centre Tecnològic those that define the system of control of the essay. In metallic sheet is very known that the operations of conformed affect to his mechanical properties and therefore to his resistance to fatigue. In this sense, the realisation of the essays of fatigue on sheets obtained in industrial conditions allows to study the effect of the quality of the cut in operations of coined, or the effect of the operations of welding and/or geometry of the cords in the resistance to fatigue of the material.

The continued bet of the Fundació CTM Centre Tecnològic by the innovation has allowed that at present they have of sufficient means to realise the control of the essays, so much by strength, trip, by means of videoextensometría or extensometría conventional, and the control and register of the temperature, always verifying that the conditions of essay simulate properly the ones of service.