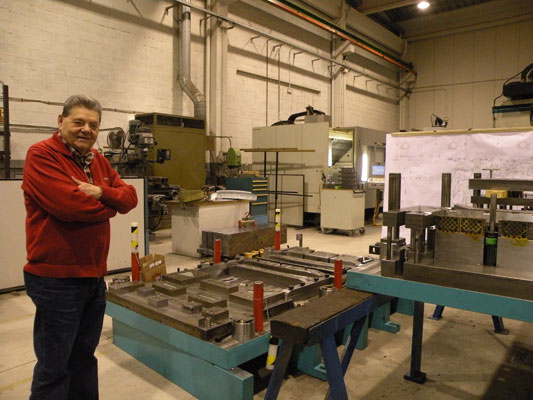

Interview to Enric Gross, director of Matrinox

To start with, it could explain us a bit what is Matrinox?

Matrinox Devotes to the matricería from his starts, in 1986. I incorporated me few years afterwards to do me charge of her and now are 11 employees. We devote us mainly to the sector of the automotive sector, working for the estampadores, subcontractors of the manufacturers of trucks. Also we are prepared to work with other sectors, as the one of the appliances, but the true is that our strong point is the one of the automotive sector.

Still there is market, in spite of the fall of sales in this market?

Himself. Although it is true that the sale of trucks has gone down a lot, the estampadores work also for international manufacturers, no only Spanish, with what keep a good rhythm of work. So to us they do not are missing us the commissions.

At present, of which park of machinery have?

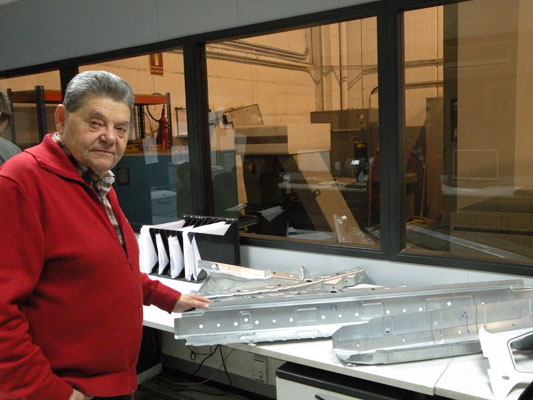

Have lathes, machining centres, machines of spark-erosion by thread, of mechanised of 5 axles, a hydraulics presses to test our matrices… Because although always they test home of the estampador, and see if it is necessary to do small modifications, the first comprobaciones do them in Matrinox.

From among this park of machinery, how many are of DMG Mori Seiki ?

Specifically of DMG Mori Seiki have a centre of mechanised of 5 axles, another centre of mechanised that it can be also of five axles, a semi-automatic lathe and a DMG 104.

What would stand out of these machines? What did them opt by them?

To the hour to choose, once tested saw that they were the ideal machines for us. Already we had had another machinery and the experience was not so good as we expected. Instead, the DMG Mori Seiki work us very well but besides have a technical service very good, what is very important for us. In the case to require a repair, are very fast, something vital for a company as ours, where the time of work and the rapidity of delivery is a decisive factor. Thus we follow trusting they, as it shows the recent acquisition, does some four months, of a centre DMU 80 EVO, for works of mechanised.

The sector of the automotive sector is especially demanding regarding standards of quality by part of his providers. How they satisfy these demands?

In Matrinox work on the planes delivered by the estampadores. Many times they ask things almost impossible, but try to approximate us the maximum possible and solve the requests of the engineers that have realised the planes. The pieces contrived by the designers suppose often important challenges for the estampadores and, in consequence, for us, that manufacture the matrices with that will realise these pieces. Nowadays they demand tolerances ínfimas and that is our daily fight. But also it is true that the innovation in machinery has helped us to solve determinate difficulties, although no always is possible all what ask and in occasions do a matrix is an authentic headache.

Which is secret to continue with a familiar ‘company' after 30 years in the market?

In Matrinox work for companies subcontractors of Ford or Nissan, mainly, from does years. The key to have a cast of customers more or less fixed is in the loyalty and this attains fulfilling with the terms of delivery, something vital in a sector like the one of the automotive sector that works ‘just in time', and in keeping a narrow relation with the customer. On the other hand, the formula to be still in foot is not spending more than what ingresa. There is not any secret, only invest in the company and in new technology. Perhaps thus we have noticed little, or almost at all, the crisis, and follow working. We have grown of moderate way and always in function of our possibilities, without abusing of the credit.

Until which point has been important the incorporation of new technology for Matrinox?

It is necessary to be in the crest of the wave if it wants to be still in the market. And the true is that the advance in machinery, the new technologies and the provision contributed by the manufacturers of machines, help us to solve the daily challenges to which confront us the matriceros. It is vital to invest in machinery and renew it constantly.

It thinks that the manufacturers of machines innovan with sufficient rapidity to the demand of the market?

Yes, of course. Constantly, and these improvements notice in the work, reducing time, costs, errors… This has facilitated us can reach the terms that demand us and solve the problems that pose . Have the support of DMG Mori Seiki is a value added to our work.