Illig facilitates the thermoforming for various molded parts

In its basic version the machines are equipped with heating top and bottom, making it possible to process materials such as the PS, PVC, APET, PAHO, PE and PP in thicknesses of 180 µm to 2.5 mm.

The RDK machines mark patterns by their manageability both its mechanical construction. The consistent use of dynamic servo motors with the most modern technology of control and regulation guarantees an exact adjustment of routes and speeds, allowing also an adjustment of basic data of the machine computer-aided. This becomes a reality greater availability, an increase in performance and improvements in the quality of the product.

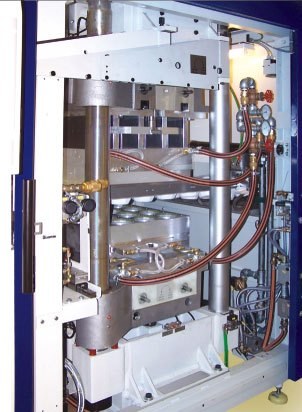

Molding/stamping station is equipped with a mobile table top and a bottom. The open-end levers, the tables and the columnas-guía for a maximum force of stamping has been optimized for optimal results of court. Necessary closing and stamping force brings to tables through double open-end levers and servo motor with pinion moved by thread. So not form transverse forces in molding tables column guides, the force is centrally introduced by the articulation of the double bent lever. The speed profile designed with accuracy of double bent lever allows you to enter the maximum force during the process of stamping.

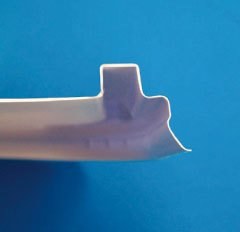

Thanks to the technique of the servodrive employed by ILLIG, with which it is possible to coordinate with great precision the movements of the table of molding with the piston of pre-shaped, an optimal distribution of the thickness of the side walls of the product can achieve. This better distribution of material allows also the same stability of the product for a lower thickness of plastic of departure. This leads to a qualitative product improvement, as for example a greater rigidity of the molded part and a few edges from sealed completely accurate and flat across the surface of seal, that are obtained by costumed chilled in the mold.

The direct provision of vacuum valves and air compressed molding station allows very short filling times for each of the cavities and thus very short cycle times. The molding can take place, choice, at the top table and at the bottom by vacuum or compressed air. To pre-select the program of moulding in the control panel are automatically performed all the required settings.

An important detail for the processing of the PP is the expansion device for transporting plastic. Through this device plastic transport pneumatically splits in the area of moulding station, was tense the plastic and prevents this way that wrinkles are formed in the moulding process. The necessary expansion value is obtained from thermal expansion of the plastic.

Four rows of resistance on the side of entry can disconnect to adjust heating upper and the lower to the passage of the transport. Thus compensates the influences of temperature of the mold for molding and cooling of the tensor framework, and avoid the marks of cooling on the side walls of the products. On the top and bottom heating, each of the rows of resistance is regulated through pilot resistance. Depending on the transport and the width of the plastic step are automatically disconnected the rows of resistance that may not be necessary. Other sequences of movements, such as aid of anti-corrosion for castings with carvings of stacking or a command of spare parts system, help to manufacture parts molded with very strong carvings.

Basic adjustment setting of the machine data computer-aided

The molded parts, e.g. bases for chocolates and biscuits, are not engaged in the stack and can desapilarse without problems, used the alternate stacking.

In the case of supplies of moulding of several rows, the buttons of stacking can be different and be prepared in several ways. In the station of stacking rows of products that are each along with others are pushed on each other and they are stacked in a single row (stacking a-B). The position of the buttons of stacking, that varies according to each molded piece, it maintains separate pieces.

Smaller series and a greater diversity of products put more requirements to the change of format

In addition to the conventional technique of fast tool change it is possible to change mold inserts and funds without removing the top of the mold. Format of the lower part of the useful parts are changed on a device for the purpose.

The modular construction of the machines RDK allows you to use the most various techniques of processes for moulding, cutting and stacking the products, which can be supplemented by a crusher mill for cutting of sheet. An intermediate frame where to use these devices is used for placement of bases of suction, to decorate the containers or for printing barcodes.

Thanks to the advantages of the technique of processes, much of the RDK machines is used for the manufacture of closures

To process material preprinted, as in the manufacture of closures, a photoelectric cell command device is available. Servomotorizado transport of plastic allowed, along with the photoelectric cell, the exact positioning of the printed plastic in the mold of moulding.

Depending on application and production requirements, the photoelectric cell is located on the machine. The plastic should be brands of printing at the distance of the reasons. The search for the brand of slow printing once adjusted progress to rapid progress takes place. Search cycle ends as soon as recognized brand impression. Plastics will continue to even transporting the distance corresponding to the correction of the mark of impression. This way of working allows regular accurately the position of the printed image.