Siemens Digital Industry Software - Software per a la gestió del cicle de vida del producte (PLM)

Tecnomatix 9

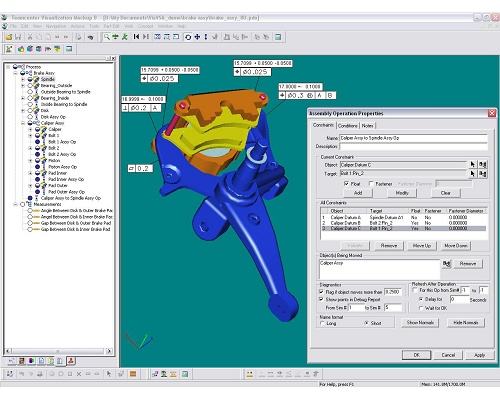

Suite Of digital manufacture: to optimise the planning and productivity of manufacture

Siemens PLM Software has announced the last version of software Tecnomatix, the suite complete of digital manufacture of the company. The numerous improvements in all Tecnomatix 9 – together with several functionalities in areas like the planning of processes, the robotic simulation and the comisionamiento)– create a destined solution to help to the companies to optimise his planning and productivity of manufacture.

The suite Tecnomatix, together with the new capacities that offers the current version, allows the engineering colaborativa and improves the productivity and the planificadores of manufacture, supporting to the companies in his effort to carry products to the market with more rapidity. Tecnomatix Also takes advantage of the software Teamcenter the suite of management of the cycle of digital life of Siemens PLM Software, like an integrated cheese cheese platform for planificadores of manufacture, of the permission of processes through the simulation to the documentation. The improvements in Tecnomatix 9 support concepts like the reuse of the best practical and the normalisation, as well as the tools help to manage complex processes like the management of the change. These tools help to increase the productivity of planning and allows to the planificadores do more with less.

Tecnomatix 9 includes several additional improvements focused to increase the productivity of planning, improvements of usabilidad and new library of tools of manufacture. Besides, Tecnomatix offers a greater integration of Teamcenter, allowing the collaboration of data of manufacture between the applications of Tecnomatix and the database of PLM of Teamcenter. Tecnomatix 9 approaches the planning and production and help to reduce the brecha between the virtual and the real. With Tecnomatix 9 enters a new solution for Dimensional Planning & Validation (DPV). DPV Allows to capture big quantities of information (ace-built) from devices of measurement in workshop and manage them in Teamcenter. The designers of product as well as engineers of manufacture can take advantage of the research detailed and functions of analysis to examine and compare data of quality from several plants and, therefore, optimise the product and process.