Drifter for machining of high precision large pieces

Interempresas traveled to Venice to meet this new machine and visit the three production plants of the Group Parpas, Famu and OMV, an group, represented in Spain by Maquinser, with many years of experience and a reputation throughout the world.

The creation of this machine so unique and specific, whose two first units have already been sold to Siemens India, for the manufacture of turbines, and Schneider Electric in Italy (another unit is in the throes of manufacture for other clients in the U.S.), reflects the experience of the Italian group in the design and manufacture of machines of high level for different sectorsas well as their great exporting background, with United States as main market.

The Invar machine is ideal for large pieces of high-precision machining as that required in sectors with large weights as the energy, Central nuclear, the manufacture of turbines or even the own manufacture of machine tools.

Also, and in relation to other kinds of machinery of the Italian group, few companies can boast of having in its customer portfolio with prestigious brands in the aviation industry such as Lockheed Martin, Boeing, Airbus, Edac Aero, Xac, GE, Snecma, Cessna, Nuovo Pignone, Spirit Aerosystems, Hitco Carbon Composites, ATK, MTU or Ansaldo.

A machine with dimensions and name to remember

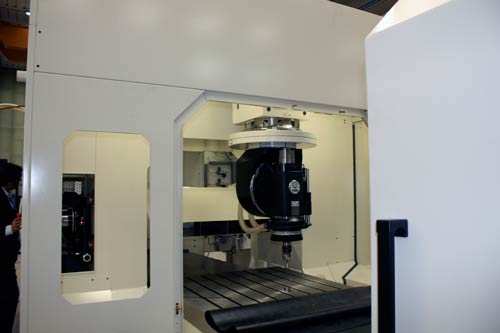

Not only the large size and precision of finishes (even a game of lights accompanied the movement of the head) called the attention of the machine at first glance. Both the design and manufacture of parts of the machine have been cared for in detail: maximum comfort and freedom of movement for the operator (cabin with movement of top-down and forward-back heated), a comprehensive thermal control of each process and piece to ensure maximum accuracy, M.T.S.S (Machine thermal Stabilization System), a unique construction of the column to avoid possible charges/deviationsIt includes an Adaptive hydrostatic system and a system of balancing weights.

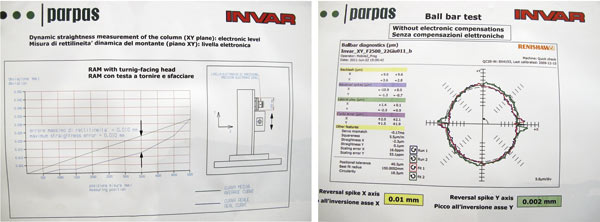

Given that the precision has always been one of the great challenges of large machines, Parpas group has spared to introduce new techniques and systems to achieve greater precision.

Even the name of the machine, which refers to one of the materials used in its construction, is special. Invar, as she pointed to Interempresas Oscar Villanueva, director of Maquinser applications, is an alloy of iron (64%) and nickel (36%) with very low-carbon and some of chromium used in the manufacture of precision parts with low coefficient of expansion (watches, physical appliances, valves of engines, etc.) and, especially, instruments for measuring length, such as those used in surveying"It's a machine that goes a step ahead of the competition, whose machines do not have the same degree of precision in technology or technology".

On the floor of Parpas was Invar machine in full and in various stages of production, so that attendees could learn the ins and outs of complex mechanism that includes in each new techniques or systems with a view to ensure the accuracy as defendant in large machines.

"The machine that we can see in the day has an average size of 5 meters and a half course of axis and can reach up to nine metres in the Invar 3 version and up to 30 metres in length." "As more significant feature, must emphasize in the five m's tour, has a precision of 10 microns movement", noted Maquinser Villanueva.

It is tailored to the client machines. The machine as such is the basis and the column with the axes of motion X, and Z the giro A, C, i.e. that it can to control 6 axes. The table may be specific or table rotation, as shown in the day, 4 x 4 and a carrying capacity of up to 100 tons of weight.

Unique thermal stabilization

The specifics of the new Invar is which includes the full and continuous thermal stabilization with integral insulation structures with an air conditioning system that maintains a constant temperature, avoiding structural deformation caused by temperature changes. The result is a high and constant precision of the machine even with the changes in environmental temperature. "To install this kind of machines, the customer will never have a thermally conditioned place because, or it is impossible either overly expensive", said Villanueva. "The interesting thing is that the machine incorporates the air conditioning on its cover". "A skin that keeps the temperature of the machine to ±1 degree". This patented technique her comes already using Parpas in other models of its catalogue of products, this being the first time used in this type of machines.

The column, key element in the process

Without weights, without accessories. This is another of the great strengths of the machine. To avoid possible distortions of the column, it has an external independent structure of the column from which hang weights and suspended masses (ATC or the platform of the operator, balances, etc.). This solution prevents any deformation or stress in the column that holds only the main function of the vertical guide and reacts to machining, achieving in this way, very high precision operations.

Hydrostatic machine

One of the keys of the machine is hydrostatic, slipping between the moving parts, even of the table, is produced by a film of oil, without physical pieces on each other.

To this end, the machine is equipped with a large number of proportional valves, patented in the House, that constantly regulate pressure throughout the area.

In addition, the position of the axes is controlled with Heidenhain rules, even the axes of rotation. For the movement on the linear axes are relied on spindles of balls, 120 in diameter and in this case, the electronics is Siemens.

On the other hand, the axes, with a speed of 24 meters / minute, incorporate a braking system. According to Villanueva, "engines have dynamic brake system, but in addition, the axis and has an additional braking system having a faster reaction to avoid damage to parts that usually have a high cost".

The bar of invar, the crux of the machine

To control the exact position of the front of the head, the machine has a toolbar of invar, connected at the head of the rule of Heidenhain. Thus, before any thermal variation, the bar offset, a way of keeping something fixed and unchanging to calculate the rest.

Axis motorized for absolute control of the process

The X axis is displaced by four torque engines, mounted in two groups positioned symmetrically to the column. Each group consists of an engine mounted on the other, which rotates the pine nuts with electronic preload directly. The dynamics of this axis is achieved by avoiding wear and reducing downtime.

"The table presented in these days is 4 x 4 meters but can be 5 x 5". The maximum capacity of load of the dividing table can reach 150 tonnes, and is designed to avoid backlash, which finally result in loss of precision. This is achieved electronically: engine makes master and one slave by force in contradiction. In this way always maintained electronically the preload with the rack. "In addition, it has a number of autoajustes that allow for example, make matchable automatically".

Versatility even in big dimensions

The machine is designed to offer the versatility required making very precise tasks or large slab of material, which has a large number of accessories that change automatically. "The values of power in this machine are also dazzling."

Machine for machining blades. One company has 140 units in USA.

Manual setting, the detail in the "detail"

In addition to all the techniques includes, Invar machine consists of other details that make it unique. "These machines were not built up in one piece." 30 Meters, and assembled parts with manual settings. The pieces are rasqueteadas, with a very fine tuning. "To merge, everything is extremely accurate."

Another technical detail of interest indicates to what extent are the points that can influence the accuracy is that rules of measurement are integrated in the area of controlled temperature to prevent expansion and that they are always in relation to the structure in which they are mounted.