Machines and solutions customized in record time

July 12, 2011

To address their business challenges, Ibarmia, family ownership group located and in Azkoitia (Guipúzcoa) was founded in 1952, he then opted for the Solid Edge 3D capabilities and a year ago has been incorporated into version Synchronous Technology. His decision has allowed him to specialize in the manufacture of machining centers of high-performance with a very advanced level of customization with a range covering from design to Assembly of products in the facilities of the clients, mainly targeting the sectors of energy, aeronautics, equipment and machining workshops. It has 71 people on staff, 20 per cent of it engineers. In recent years has substantially increased its export capacity sold 75% of its production to countries such as Germany, Italy, France, Switzerland, Austria, China, USA, Mexico and Brazil. In 2008 it reached 24 million euros of turnover.

"Thanks to the power, agility and speed of Solid Edge with Synchronous Technology, are able to generate proposals for machines and solutions tailored to our customers in times really record." "Before submitting a tender had been months, now virtually in a week we show very complex solutions," stresses Koldo Arandia, CEO of Ibarmia.

- Business initiatives

Search for greater competitiveness and specialization

Shorten delivery times

- Business challenges

Cover from the design to the installation of machines

Manufacture machinery of great scope and complexity

Work with different materials and processes

- Keys to success

Realization of modifications without delays and recálculos

Easier to move sets of size

Use of the Solid Edge drawings for commercial work

Quality levels for manufacturing and Assembly

- Results

Complete redesign of parts within 4-6 times faster

Reduction in three times the time of marketing

Reduction of costs and improvement in productivity

Ability to offer better prices

An end-to-end tool

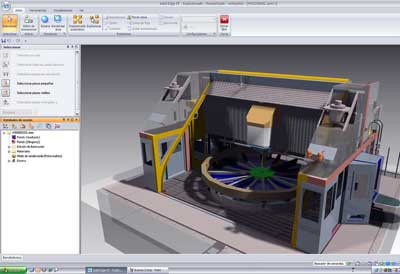

Solid Edge with Synchronous Technology is the standard design solution of the company, which have 11 licenses, and is present in all workflows involving their products from start to finish. His drawings and plans are not limited to the environment of the technical Office, being key pieces to other departments such as commercial in pre-sales, manufacture and Assembly tasks. "Since we have Solid Edge have a great advantage: be able to show our clients solutions that we have not developed yet in our workshops, but we have designed by their demands and consultations." On the computer we can view them in a very concrete way and discuss the details with them. "It has a great impact, the client sees what you are proposing" - pointing Xabier Errazu, responsible for trade of Ibarmia-"even in brochures, increasingly introduce drawings in 3D because we highlight more details it with a photo".

Ibarmia Innovatek in Azkoitia (Gipuzkoa) is dedicated to the manufacture and sale of machines - tool.

When the client approves the first designs, prepares the offer with the final designs of the machine. Once accepted, linked to an ERP Purchasing Department distributes all the elements to build, purchase the material and is machined to the product in their facilities. Move to Assembly and carried out the necessary checks. Once mounted the machine, it has information for issuing her disassemble, load it and perform the complete installation in the workshops of the client. All these processes benefit from the high quality and information to facilitate levels generated with Solid Edge, avoiding the dreaded errors and loss of time in his interpretation: views rendered, auxiliary and sets, complete lists of materials, explosions, etc.

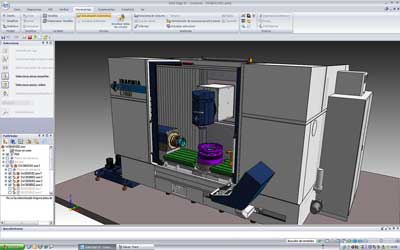

Machines of up to 3,000 pieces

Ibarmia daily confronts the challenge of manufacturing machines that can reach 150 tonnes and 12 metres in length, with a total of up to 3,000 pieces. "Elements that we design there are pieces of such complexity as pieces of formed, fundición… and even textile." "Thanks to Solid Edge with Synchronous Technology, undertake them with great ease", said Xabier Ibarmia, technical director of Ibarmia. As an example, emphasizes its strength to face the difficulty of machines of the wind sector with five axes, 5 degrees of freedom, which requires designing rotary axes in different planes.

Your use of the sheet PSM module is also remarkable: "Have given you a twist when not performing any level of construction, sending all solids directly to our supplier, in such a way that we have reduced the execution of a fairing four times what it tardábamos three years ago", says Xabier Ibarmia. In the redesign of pieces and in particular in the realization of benches, where all the moving parts of a machine are settle, synchronous technology has also made improvements. These are pieces that are never repeated, are custom: "Tend to assume others are already developed." Synchronous Technology allows us to modify and stretch in a very simple way the faces and dimensions of the old. The basis that we would have with three or four touches. In a day or day and a half realizaríamos the complete design of the base and the level for the release to production. "2D will take four to six times more," says Ion Ander Badiola, responsible for engineering of Ibarmia.

A revolutionary impact

Ibarmia is aware of the positive that has been the introduction of Solid Edge with Synchronous Technology. Technical improvements such as agility in carrying out changes by avoiding delays in recálculos or greater ease to move sets of scale due to the reduction of the size of the files, and versions have been translated into benefits for your business to the have reduced time to market, investing only one third of the needed previously, reduced costs and improved productivityenabling them to offer better prices to customers.

"The impact has been revolutionary." Designers gives them courage and security to attack challenges. Unthinkable to develop 2D things become easier to shape in 3D. You feel that puedes… maybe with a 2D package gives panic make complicated geometries and has no where to begin the development of the piece. "Synchronous Technology allows you to win that security and the feeling that you can achieve it," considers Xabier Ibarmia.

In this discovery of Solid Edge, Pixel systems (distribution company of Siemens PLM Software products in the North of Spain and settled in Elgoibar, Gipuzkoa) has been: "we had to give a one-man workshop to remove the bandage of the 2D and we do not repent." "Really, the machines we build are thanks to Pixel opened us the way and has been a success", recognizes Xabier Ibarmia. Today Ibarmia confidence in Siemens PLM products is total and an expansion of Solid Edge licensing could join soon an investment in other products of Velocity Series, such as CAM Express family, for the manufacture of machines with programming, and Femap, for finite element analysis.