Mechanised of dental structures

In the last years have predominated the aesthetic caterings based in the employment of ceramic feldespáticas, aluminous or circoniosas like main material on a dental structure, causing the need to guarantee a minimum level of adhesion of the ceramics on the structure, that can be manufactured by means of processes of milling, colado and sinterizado.

The technological advances allow to transform different sectors, and the odontology is one of them, since they are giving advances in diagnostic, in new systems of scanned intraoral that substitute to the traditional impressesion and, of course, in the applications CAD/CAM for the manufacture of crowns, implants and bridges, causing that the conventional processes employees in the phases of a process of implantología oral are realised of digital form, supposing an authentic revolution in the sector.

Inside this revolution and analysed the influence of the mechanised like fundamental technician for the prothetic technicians and of manufacture, with the present article go to review the scope of the mechanised by milling of the dental structures.

1. Dental structures

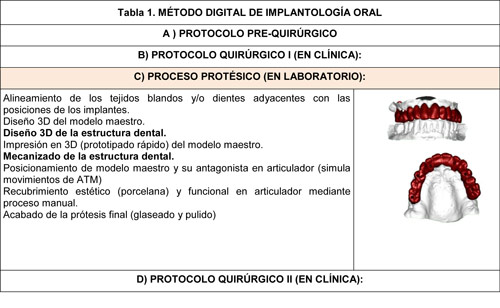

Before analysing the process of mechanised of a dental structure, is convenient to remember in what consists a process of implantología oral based in digital technology and as we arrive to the definition of the structure to mechanise. It is necessary to take into account that in these moments realise big advances in the sector of dental implants regarding the diagnostic by image 3D, to the manufacture of systems of surgery guided and in the manufacture CAD/CAM of structures for prosthesis implant-supported. The basic protocol would be the indicated in the figure 1.

This new process of creation of dental structures implant creame by means of systems CAD/CAM allow to realise works of form homogénea attaining obtain dental prostheses of greater quality.

The digital method of implantología oral bases in different protocols. It is in the prothetic protocol realised in the laboratory where takes place the design 3D and mechanised of the dental structure.

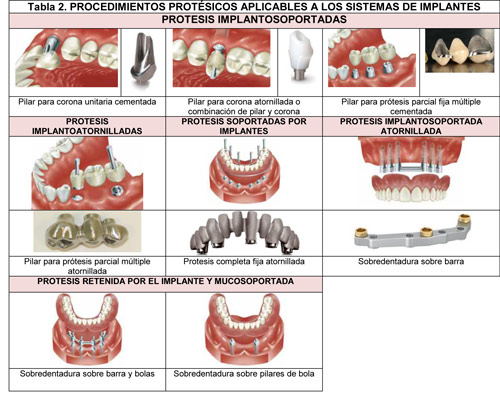

On the other hand, also is necessary that review the scope of the different prothetic procedures applicable to the systems of implants (table 2):

From the different prostheses indicated and of his function, it is necessary to take into account that the dental structures have to answer to three principles biomecánicos:

- Retention so that it do not produce his extrusion.

- Support to resist the strengths of intrusion that act on them.

- Stability of the prostheses for oponerse to horizontal strengths or of shearing and rotation.

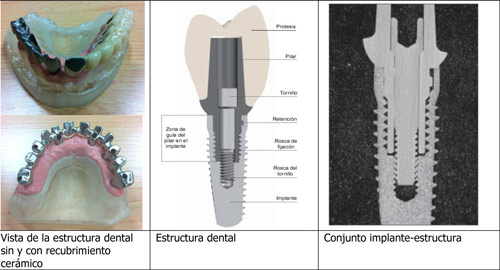

The support comes given by the implants and by the osseous density of the jawbone in that they have placed the fixations. The stability or capacity is lower if the structure finds badly fixed and generate strengths that can cause the break of the element of retention (screw or adhesive) (figure 2).

In the case of the prostheses atornilladas, is difficult to achieve an adjust passive on the pillars of retention, and therefore, during his operation biomecánico, create tensions that can cause the fracture or lost of screws, as well as transmit tensions to the prothetic structure or to the interfase bone-implant. What greater is the number of pillars of the structure, more difficult is to obtain a structure atornillada passive.

A first solution is the selection of metallic alloys of high module and elastic limit that avoid the plastic and elastic deformation, in front of the strengths biomecánicas, whereas to achieve the adjust passive of the structure on the pillars, that is to say, the contact circunferencial and simultaneous of all the pillars on his respective implants and of the prosthesis on his respective pillars, stir levels of precision of 10 to 50 micras at most unfit allowed.

The studies realised indicate that the structures manufactured by means of milling experience a lower deformation during the stage of ceramización in comparison with the processes of colado and sinterizado. The low distortion of the structures milling is atribuible to the high thermal sensors stability of the metallic part when being free of residual tensions or microporosidades. If besides it achieves a homogoneidad, planitud and precision in the destined surfaces to be in intimate contact with the dental implant, justifies that the structures milling do not require manipulation to have a better passivity in the mouth of the patient.

Another key appearance of the dental structure is the adhesion of the ceramics. It is important to guarantee a minimum level of adhesion of the ceramics in metal structures of chromium-cobalt and titanium obtained by means of milling, colado and sinterizado.

2. Dental alloys

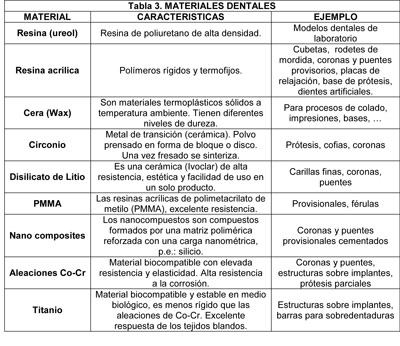

Regarding the materials employed in the manufacture of dental prostheses, it is necessary to stand out the indicated in the table 3.

If we centre us in the metallic alloys, the American Dental Association (ADA) establishes the following classification of the alloys in function of his composition:

- high noble Alloys, with a percentage in weight of equal noble metals or upper to 60% and of equal or upper gold to 40%. Inside this group frame the alloys of pure gold (types I-IV), gold-platinum-palladium, gold-platinum, gold-palladium-silver, and gold-palladium.

- Noble alloys: with a content in equal noble metal or upper to 25%. To this group belong the alloys of basic palladium, in addition to other alloys like the ones of silver-palladium, palladium-copper, palladium-cobalt, palladium-gallium-silver, palladium-gallium-silver-gold, palladium-earn-gallium, gold-earn-silver-palladium and gold-earn-palladium-Indian.

- Alloys with predominance of basic metal, whose content of noble metal is inferior to 25%. Inside them they include the alloys of titanium, nickel-chromium and cobaltocromo.

The metals considered noble are the gold, platinum, palladium, iridium, rodio, osmium and ruthenium.

The alloys of use odontológico, have properties and characteristic established by different international norms ISO. In all the cases will have to be biocompatibles in the triple slope of no toxic, no alergénicas and no carcinogenéticas. They will be susceptible of a correct finishing and polishing to contribute aesthetic qualities and avoid the corrosion; will have a high resistance, so much to the compressesion as to the traction; interval of fusion no too wide, high elastic limit, suitable rigidity to each case, moderate ductility and big hardness.

The most usual alloys are the alloys of cobalt-chromium, titanium and palladium-gold. We see his main characteristic.

2.1.- Alloys of cobalt-chromium

These alloys are biocompatibles, do not have nickel (Neither) and are not alergénicas, toxic neither carcinogenética. They compose basically of cobalt, between a 35 and 65%; and chromium, in proportions that oscillate between a 20 and 35%. The module of elasticity, the elastic limit and the resistance to the split of the cobalt-chromium are the most elevated of all the alloys used in odontology. His big elastic limit allows practically avoid all plastic deformation of the structures of prosthesis. His high module of elasticity, whose value duplicates to the of the gold, makes possible to achieve the same rigidity that with this metal, but to thicknesses much finer, allowing a lower volume of the prostheses (figure 3).

2.2.- Alloys of titanium

The commercially pure titanium, is the used more frequently in the manufacturing of prosthesis. They exist four types of this metal (as To.S.T.M.).

The pure titanium of degree I employs in bars on implants; the pure titanium of market degree II (You CP 2) advises for the fixed caterings subjected to small mechanical efforts, as well as for the manufacture of cofias in individual crowns and bridges of small extension mechanised. The titanium of degree IV (You CP 4) uses for the manufacturing of partial prostheses removibles subjected to greater loads. In addition to the pure titanium can employ any of his alloys eat: You-6To the-4V, You-15V, You-20Cu, You-30Pd 49, 107, fundamentally the first (figure 4).

The titanium has a low module of elasticity, by what the structures coladas with this metal are less rigid that the ones of cobalt-chromium. They present big resistance to the fatigue, to the tension and deformation and big ductility. It is a material with an excellent biocompatibilidad and also comports like material no toxic, antialergénico and highly biocompatible.

2.3.- Alloys of palladium-gold.

The noble classification refers generally to all the alloys with palladium like base that contain between a 54 and 88 % in weight of palladium. Since his content in silver is low (3 % in weight), does not cause greenish colour of the china. The use of the noble alloys has extended thanks to his optimum mechanical properties and to his good adherencia to the china, since the ancient advantage of his lower price has disappeared with the elevation of the price of the palladium.

3. Application of the mechanised

3.1. Technicians of mechanised

The prothetic technicians and of manufacture have to achieve mechanise the components demanded, of automatic form, with the lower cost, in the lower time and with the quality demanded by the customer.

In the case of the prothetic technician, and in front of solutions based in the manufacture by start of material, has to apply these criteria especially type of machines-tool and to the different prostheses, implants and structures of zirconium, chromium cobalt, titanium, polimetilmetacrilato (PMMA), wax, ceramic and disilicato of lithium. For this has to use technicians of mechanised optimised and based in the utilisation of machines-tool of 3 and 5 axles, and applications CAD/CAM with the functionality implanted that it demands in the operations of mechanised dental.

Exist two lines of mechanised differentiated in the dental laboratories:

- Mechanised of soft materials (PMMA, wax, resins and dust of zirconium pressesing).

- Mechanised of metal structures (titanium and/or cobalt-chromium).

Said operations of mechanised, demand machines-tool adapted with the following functional characteristics:

- Size reduced to adapt to the available space in the dental laboratories.

- Mechanised of hard and fragile materials like the ceramics of glass and synthetic special, as well as the milling to high speed of demanding metals, like the titanium and the chromium-cobalt

- Mechanised of complex geometries by means of flexible cinematic configurations and of 3 to 5 axles.

The conventional technicians of mechanised and sintering do not achieve a reliable commitment in front of these demands. The mechanised conventional is limited regarding the time of mechanised, the size of the tools and to simple geometries. The mechanised by spark-erosion allows the mechanised of a wide range of forms and sizes but only is adapted for his use in conductive materials. In the case of the sintering, the utilisation of the laser causes a thermal sensors modification of the surface that can have a negative impact in his final utilisation, especially in applications that require high reliability.

Regarding the technicians advanced of mechanised (figure 6), has of machines-tools of mechanised to high speed and mechanised ultrasonic.

The mechanised to high speed is the most used technician for the manufacture of dental components in resistant materials like the alloys of Co-Cr, titanium, PMMA, wax and zirconium pressesing.

In the mechanised ultrasonic, there is not thermal sensors influence, chemical and electrical, do not alter the physical properties of the piece and do not produce changes in the chemical composition and in the microstructure of the material. The mechanised ultrasonic is a viable alternative to generate complex geometries in materials advanced like the vitrocerámicos, zirconium sinterizado, these can mechanise with rapidity and precision with machines-tools with cabezales of ultrasound of 42.000 rpm and 30.000 impulses every second.

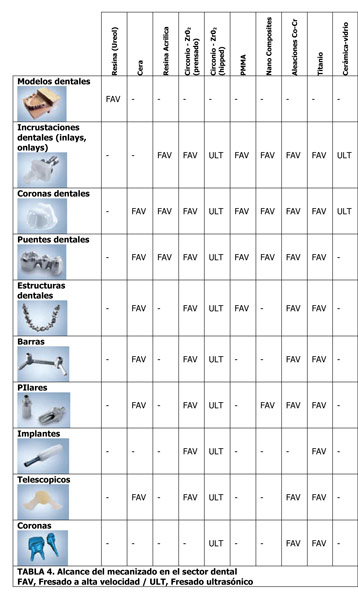

The scope of the mechanised to high speed and the mechanised ultrasonic in the manufacture of components for the dental sector remains resumido in the table 4:

The evolution that are suffering the dental materials and his prothetic application, do that the mechanised with refrigeration was minimum save for the mechanised of some dental structures (bars on implants), being the mechanised in dry the clearest option.

3.1.1. Mechanised conventional, of high performance and high speed (MAV)

The mechanised of high performance does reference to the utilisation of big advances and depths of cutting but keeping the speeds of conventional considered cut, obtaining as resulted shavings of big size and the need to have of machines-tool with cabezales of big power and rigid structure.

Regarding the mechanised to high speed, bases in keeping the section of shaving and increase the speed of cutting (20.000 rpm / 1.000-2.000 m/min.). His application is conditioned to light alloys and of high index of start, as well as material toughened, to the employment of machines-tools with specific functional characteristics, to the generation of strengths of cut reduced that they cause a lower thermal sensors transfer.

The milling is the dominant operation in the mechanised of dental prostheses, since it is necessary to mechanise geometry with form of cavities, profiles, slots and edges. The pieces are small with a tax of start of material minimum, mechanise in an alone position of subjection, guaranteeing the absence of deformations and the stability of the dimensional and superficial precision.

The key of the mechanised of this type of pieces and his alloys, finds in the phase of programming CAM, since it is necessary to know define the strategies of milling (paths) for the operations of desbaste and finishing that generate a minimum wear of tool (see section 3.2.), in combination with an optimum selection of tool of cut, so much in material of cutting (coatings) as in geometry of cutting.

3.1.2. Mechanised by ultrasounds

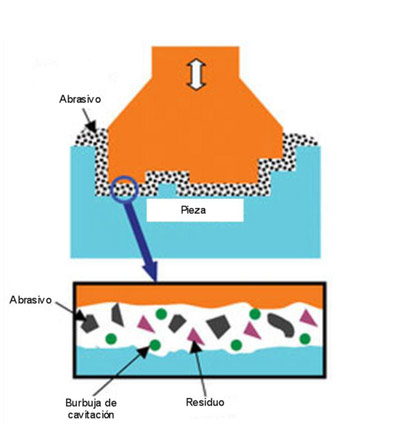

Is a method of mechanised of fragile and hard materials, with high levels of precision and superficial quality (Ra=0,2 µm), that bases in the elimination of the material of the piece by means of a tool that turns (50.000 rpm) and that displaces in axial steering (ultrasonic vibration, 20 kHz) using an abrasive liquid that besides serves to refrigerate the piece.

The process bases in an electrical signal of low frequency that applies to a transductor, that converts the electrical power in high frequency (20 KHz) generating a mechanical vibration (figure 8). This mechanical power transmits to the conjoint mango-tool generating a unisteeringal vibration of the tool in the ultrasonic frequency and with an amplitude known lower of 0,05 mm. The level of power for this process is in the interval of 50 to 3.000 watts and the pressesure applies to the tool in shape of static load.

Between the tool and the piece there is a constant flow of abrasive in suspension, that composes of grains of diamond, carbide of boron, carbide of silicon and alumina, that are suspended in a chemical solution or water. In addition to providing abrasive grain to the zone of cut, this solution allows to delete the waste. The vibratory tool, combined with the abrasive, wears out the material uniformly, leaving a reverse image of the form of the tool.

Unlike the conventional methods of mechanised, the mechanised ultrasonic produces a minimum superficial damage and an invalid thermal sensors exchange between the tool and the piece. The quality of the ultrasonic cut provides a reduction of the stress and a lower probability of fractures caused by residual tensions, that could cause the break during the life of the product.

3.1.3. Functional characteristics of the machines-tools for the dental sector

The main difficulty of the mechanised in the dental sector roots in the scarce time of planning of the strategies of mechanised, that is to say, the times of delivery are very reduced, the mechanised of the structure is an intermediate step of the process and besides each geometry is only. We can not speak of manufacture in series.

The stress generated by the fast entrance and exit of the piece to mechanise, strength to the integradores of systems to generate strategies of mechanised normalised for each type of prosthesis. The strategies differentiated regarding the geometry of the element to mechanise serian:

- Tops cementada individual

- multiple Bridge cementado

- Carilla and incrustación

- Unitary atornillado on implant

- female Geometry

- Aditamento unitary for cementar

- Bridge atornillado on implants

- Bar retentiva atornillada on implants

- dental Model

- surgical Splint/download

In when to the material that mechanises , presents in shape of disk and therefore it is necessary to think in the functionality of movements that require in the husillo and in the material (figure 9), as well as in the selection of tools and the calculation of the parameters of cutting.

In the machines-tool of 4 axles, the movement +And does not realise , since the disk is fixed in this axis and does not turn, of this form can remain zones retentivas without mechanising and would be necessary to adjust the geometry to avoid it. Some systems CAM allow this modification achieving mechanise the majority of the dental structures without need of the axis +And (figure 9).

In the machines-tool of 5 axles if it can realise the movement +And, by the expense of a more complicated structure and therefore more expensive, since the combination of movement bases in the utilisation of a circular table with effect divisor (figure 9).

The functional characteristics ideals of a machine-tool for the mechanised of dental structures would be:

- Surface reduced in plant (+/- 3 m2).

- Capacity of movement of 4/5 simultaneous axles.

- Combination of the mechanised to high speed and the mechanised ultrasonic.

- Linear motors to achieve high accelerations and fast positionings.

- Speed of the husillo, 30.000 / 60.000 rpm.

- Warehouse of tools with capacity of XX to YY tools.

- Prerreglaje Of tools (+/- 1 µm)

- Capacity of production disregarded by means of:

- Automation of the load and download of tools

- Paletización standard and cambiadores of palé.

- Possibility to integrate a system CAD/CAM to process the pieces and the manufacturing of the program.

- Recirculation of the liquid refrigerante, to collect loose particles of Co-Cr, You, etc.

- Area of work with team of succión for withdrawal of residual particles in the mechanised in dry.

- Streamlining in stainless steel for protection of internal organs of the machine and avoid the corrosion produced by the work of zirconium.

- Level of inferior noise to 60 dB for work in laboratory.

3.1.4. Functional characteristics of the tools of cut

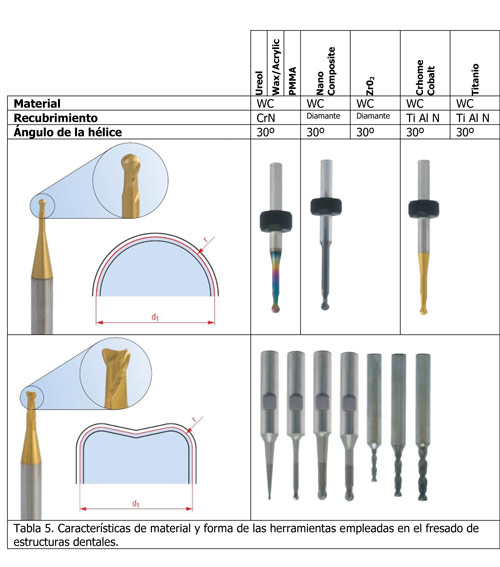

In the operations of finishing and of semiacabado employ milling cutters of hard metal. The most usual diameters are inferior to 5 mm and go from conical milling cutters of spherical tip of 0,3 to 2,5 mm for finishing, to milling cutters of ranurar straight or tóricas of 2,5 mm, and broaches of 2,5 mm for mechanised half (table 5).

In the case to mechanise connections to implants will use flat milling cutters until 0,5 mm and broaches of diameter 1,4, 1,6, 1,8, 2,0 and 2,5 mm, being the metric used by the manufacturers of implants.

Regarding the coatings of the milling cutters, the manufacturers of tools, recommend the combination of a sustrato of hard metal with micrograno with a coating by PVD resistant to the wear. This composition confers him edges of cutting very acute, resistant to the wear and to the microastillado, what makes possible to remain more time in the cut with greater speeds. The tolerance in radius is of +/- 0.005 mm and in diameter of +/- 0.01 mm.

3.2. Functional characteristics of a system CAD/CAM of dental application

The dental laboratories demand to the systems CAD/CAM two qualities: flexibility to be able to generate and receive the data without restrictions by means of archives based in open standards, p.And.: Archives in format STL and, on the other hand, ease of execution during the design and programming of the different prostheses.

3.2.1. Digitalisation of the data

The source of the data can be: the muñón in mouth, the muñón in the model, the encerado of the prothetic structure and the complete model of the mouth of the patient. Each system of digitalisation uses a determinate source.

The digitalisation can be:

- In clinic by means of a camera intraoral.

- In laboratory, by means of scanners that digitalizan the models of plaster obtained from impressesions of conventional way: scanner 3D tactile (type CMM) by direct contact or scanner 3D optical (laser and of light structured).

The data obtained during the scanned, have to be precise and reliable so that the final result of the prosthesis was in accordance with the adjust minimum demanded.

3.2.2. Design by computer

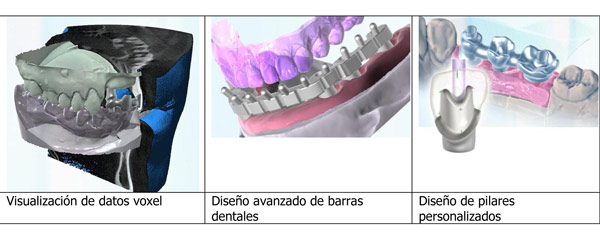

A system CAD for dental applications has to give answer to the following exigencias of design of dental caterings and interconnection with other systems:

- Design of crowns, cofías and anatomical bridges, incrustraciones (inlay/onlay), carillas, wax-up digital for milling, telescopic, pillars customised, bridges cementados and atornillados and, dental bars.

- Virtual articulation (dynamic occlusion)

- Visualisation of data voxel (TAC).

- Representation photo-realistic of the dental caterings.

- Connection with systems CAM.

- Integration with scanners 3D.

Does not be necessary to forget, that the quality of the mechanised depends to a large extent of the precision of the design generated by the system CAD (mallado).

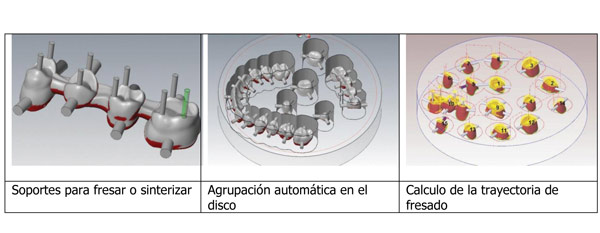

3.2.3. Mechanised computer-aided

The process of milling regarding the definition of strategies (paths of mechanised) realises by means of a system CAM. Already we know that it realises in machines-tool of numerical control of 3 to 5 axles. Some current solutions in the dental sector base in the utilisation of centres of milling own, to which sends the information obtained from the scanner situated in the dental laboratory via ecouriers and realise the structures in roughly 48-72 hours.

A system CAM of dental application, has to answer to the following functional characteristics:

- Matter geometries in format STL or native of individual or multiple form and from scanners or of CAM dental known: 3 Shape, Cynovad, Cercon, Dental wings, …

- Handle all the types of present machines in the dental and industrial fields: 360SDM, Agie Charmilles, Charlyrobot, Datron, Dent-Tec, DMG, Lilian, Lycodent, Imes, Isel, Kavo, Mikron, Real Mecca, Roland, Röders, VHF, Wieland, Willemin Macodel, Wissner, Witech, Yenamak, etc.).

- Parameters of the configuration and library of post-processors machines-dental tools, included the possibility of development or specific adaptation of post-personalised processors.

- Gestión of stocks: disks, bars, implants, chromium cobalt, etc.

- Gestión of processes: manufacturing, control of losses of material, collisions, recorded of the identifier of the element (GO).

- Assistants to guide to the operators during the manufacturings by means of the automatic location of elements, of lines of margin (cervical limits), of orientation and position of elements, of connectors of elements and his pre-cutting.

- Simulation of the mechanised with cinematic machine.

- Data of cut optimised for all the materials (chromium cobalt, titanium, zirconium, ceramic, wax...) Included the mechanised of both MAV (mechanised of high speed).

- Mechanised multigamas on a same support, to mechanise elements on a same block of material with different conditions of cutting.

- Mechanised 4 or 5 axles positioned or continuous, to generate continuous paths and without collisions between tools and the tooling of subjection. Remecanizado Of particular zones (undermined). Automatic detection of holes of implants.

- Fast generation of programs NC and format ISO or conversational.

- Realisation in the models mattered of specific actions eat: insertion of interface in an implant, detection of axles of implants and of the attachment pillar-implant, extraction equipment equipment of the muñón dental and of the cavity of the jaw from a mesh scanned intraoralmente, creation of parametric dental crowns from the model CAD and of models scanned.

- Integration with systems of fast generation of prototypes (RP).

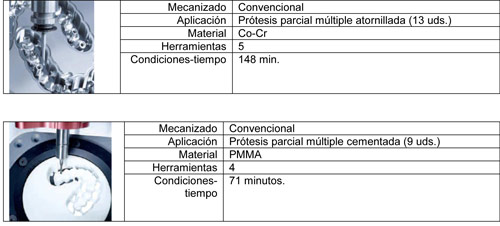

4. Examples of application

To continuation detail some examples of application:

5. Conclusions

The manufacture of dental prostheses finds in a process of innovation, so much by the utilisation of open systems, where all the elements that take part in the process of design and manufacture are compatible between yes, as by the implantation of machines-tool of CN of 5 totally automated axles to achieve a mechanised of high performance by start of material or by ultrasounds.

In the dental structures is difficult to achieve an adjust passive on the pillars of retention, and therefore, during his operation biomecánico, create tensions that can cause the fracture or lost of screws, as well as transmit tensions to the prothetic structure or to the interfase bone-implant. The dental structures manufactured by means of milling are a clear alternative to the processes of colado and sinterizado, offering an optimum passivity in the mouth of the patient.

The advances in dental materials biocompatibles and with aesthetic properties, demand innovative answers and integrated cheese cheese to the developers of solutions CAD/CAM and to the manufacturers of machines-tool and accessories, so that it increase the quality of the dental caterings and the efficiency and productivity of the laboratories.

References

- Camlog implant position planning. Camlog Biotechnologies. www.camlog.com

- Castle of Oyagüe R., (2001). Implantoprótesis Fixed cementadas. Faculty of Odontology UCM.

- Craig R., (1998) Material of odontology restauradora. Books. Madrid: Harcutting Brace [10ª ed].

- García, David, scientific Team Avinent, Centre of Investigation in Engineering Biomédica (CREB-UPC). Study of the dimensional change produced by the load of the ceramics of a structure realised from different processes: milling Protech, colado and sinterizado.

- García, David, scientific Team Avinent, Centre of Investigation in Engineering Biomédica (CREB-UPC). Comparative study of adjust them of a structure realised from different processes of manufacture: milling Protech, colado and sinterizado

- López of Lacalle Marcaide, LN., (2004). Mechanised of high performance: processes of start. Technical editions Izaro.

- Manual of prothetic catering. www.zimmerdental.es

- Milling Tools for the Dental Industry. www.emuge-franken.com

- Misch CE, (1995). Implantología Contemporary. Madrid: Mosby/Doyma.

- Palani Chinnakaruppan and Thomas To., (2008). Ultrasonic Machining. By Fote March 1. www.bullen-ultrasonics.com

- Sánchez Turrión To, et al (2000). Implantoprótesis cementada And atornillada. Dental gazette 2000; 113: 88-100.

- Serra-Prat, Josep. Study of adhesion between a ceramic feldespática and structures of chromium-cobalt milling Protech, coladas and sinterizadas. www.avinent.com/es/investigacion/documentacion-cientifica/

- Suárez MJ., (2003). Evaluation of the sealed marginal of crowns of titanium colado and mechanised with two lines of terminación. Faculty of Odontology UCM.

- Ultrasonic 10 / Ultrasonic 20 linear. Dental Series. www.dmg.com

- Wataha JC., (2002). Alloys for prosthodontic caterings. J Prosthet Dent; 87: 351-63.