Euromold and Turntec facilitate the path to the final piece

Said it Diana Schnabel, responsible for Demat, the organizing body of Euromold, at the opening of the fair and true: there is, at least in Europe, a fair with this concept and these dimensions. Its value, however, is not its dimension, not at least when compared with the fairs German, usually close to the excess. Its main asset is to bring together in a same place to companies dedicated to the design, which made prototypes or machines for prototypes, to mould manufacturers, plastics transformers and the builders of machines for machiningas well as to others many software, CAD/CAM, etc. In the 2004 Edition, in Frankfurt, as always, from 1 to 4 December was again, like last year, the focus on "rapid manufacturing" and a greater presence of machine tools.

This time the number of exhibitors fell significantly over the previous year, from 1530 to 1,502, slight decline attributable, according to Diana Schnabel, the difficulties which the industry is going through. The goal for 2005 is to reach the 1,600 exhibitors, and in the case of Euromold, is that it is customary that they attain their goals. The 2005 Edition will take place from November 30 to December 3.

In regards to Turntec, the fair of turning that Edition 2004 is held simultaneously in another ward of the same Fairgrounds of Frankfurt, with 353 exhibitors from 15 countries it exceeded last year and received almost 15,000 visitors a 47 percent increase over the previous year. Added to 50 percent more exhibitors last year made clear that this trade fair, in its third edition, it is still in phase of growth. Turntec 2004 is also reaching high levels of international participation. Already holds a 25 percent international participation.

As I said before, none of them is not a fair that stand out due to its size, but does not offer significant figures: 74.800 square meters of exhibition in this 2004 edition of Euromold, occupied mainly by German companies (69.2 per cent). The participation of non-German exhibitors declined slightly by about two points and Italy still remaining as the country with more representatives, representing a 17 per cent of the exhibitors, followed by China (12.7%), Turkey (7.8%), France (6.9%) and Spain and the Netherlands, with a 5.3% each. He especially emphasized the substantial reduction of enterprises of Portugal, which represent 8 per cent, fell to 4 per cent, something which could be seen through the corridors, because in previous years the Portuguese moldistas came with flashy booths and caught the attention of the visitor.

As a Spanish Euromold exhibitors, in the catalogue of the fair, are the following companies:

- ABM moulds,

- Galician Moldistas Association,

- Bermaq,

- Standard Bolexp,

- Chamber of Commerce of Vigo,

- Buildings mechanics Solé,

- Coproin,

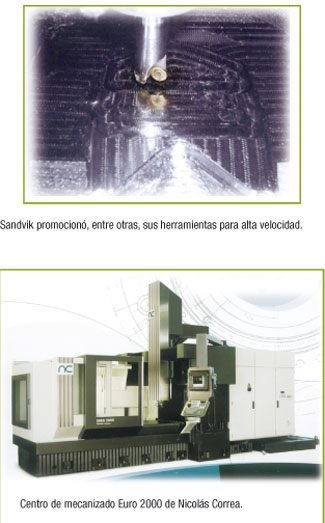

- Nicolás Correa,

- Cumsa,

- EPSA,

- FEAMM,

- Hispamoldes,

- Lebario industries,

- Irumold,

- Laip,

- Buildings mechanics Marés,

- Molmasa,

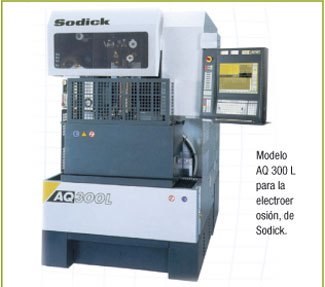

- ONA EDM,

- Workshops Almarcha,

- Festivals workshops,

- Troquelería Ura

- Tromosa, and

- Vert.

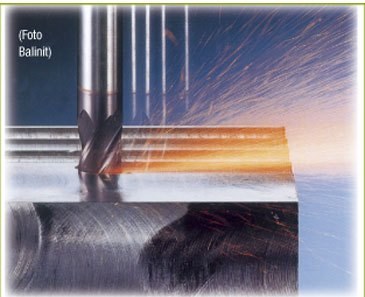

Euromold is a fair would also leave room for the enjoyment and thus put it clear this time exposures of old motorcycles, cars impossible and strange single-seater vehicles, as well as Twikes, hybrids of bicycles and cars with pedals and electric power. In the Pavilion of to the side, a center of milling down the visitor back to the ground. A visitor who, by the way, comes primarily from the sector of the car (almost 20%).

He was also in Euromold Ona EDM, for the first time, with its 300 DB and AE 300 machines. Another known name of the machine tool, Mori Seiki, presented three machines: a lathe NL 1500 SY/500, a NVD 400 DCG machining center and a milling machine for micropiezas

Mazak (in Spain, represented by Intermaher) and Haas (Spain Temaqser), had two separate stands at Euromold and Turntec fairs. In particular, Mazak exhibited at Euromold a Variaxis 630 - 5 X, while in the fair of turning presented two Lathes: Quickturn 200 Nexus and Integrex 2000 II S.

Also, Balzers also featured a striking stand where its usual products promoted.

Products for the future

The Eosint P 700 is also increased. With a volume of construction of more than 150 liters and 50 W double lasers this machine is proving his skills for years and now offers a better resolution and productivity.

The Eosint M 270 to DMLS, a technique that is being used to manufacture of injection moulds and other tools, as well as prototypes and, increasingly, tooling for production could also be seen. The machine was presented for the first time in 2003 and is being marketed with success since summer of 2004. Now presents numerous innovations, such as a laser with a very small focus diameter, to achieve a better resolution and quality of the piece. Also improved the speed of the engines and the variable focus technology.

In the field of materials, has launched an improved polyamide, PrimePart, thin and high resolution, which expands its range of polyamide-based materials. An interesting example is also the first material with retardant of flame to the sintered by laser of plastic.