SSI Schäfer carries out an innovative picking Desigual-chain solution

November 22, 2010

Complying with these criteria it is possible to minimize the effort of the staff in the shops. Apart from that, the logistic processes in the textile trade are based on the following two main business processes: 'initials' and '600nt'.

The fashion world offers at least two collections per year - spring/summer and autumn/winter. In two campaigns (or also calls 'initials') are delivered clothing to different points of sale for the start of the corresponding season. Such campaigns, as well as the corresponding dates, are already planned months in advance. In addition, garments are already assigned to the different points of sale before its manufacture. In principle, these 'Initials' has a large total volume, but individual garments are successively provided for weeks from manufacturing to the distribution plant. Therefore, the assortment of clothes is not registered in the store completely until shortly before the date of scheduled delivery of the campaign. To ensure that all orders are delivered on schedule and that despite the large volume of orders, the campaign is processed efficiently, it is necessary to begin with the preparation of orders to store the first articles of the campaign. The logistical challenge of these orders of campaign is that you have to launch the preparation of orders at a time, when not yet available all articles for orders. Indeed, orders not can be completed until the last reception of goods of the campaign.

But, in addition to the campaigns, continually replenishment orders. Through these '600nt' is replaced the merchandise sold in stores. They are characterised by their small volume of delivery order and execution cycles minimum.

The process of optimum picking for Desigual combines two business processes referred to in an efficient manner. Other conventional systems, on the other hand, are subject to various restrictions and as a result the logistical costs increase.

To deal with these disadvantages, SSI Schäfer has developed a method of picking adapted processes and needs of the textile trade. Thus, you can keep pace with the enormous speed of expansion of Desigual.

Innovative system of classification (sorter) and drawers combination

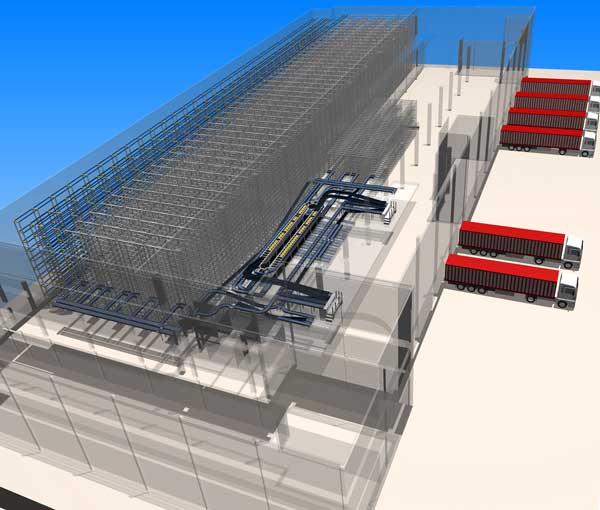

Compared to conventional systems, the solution of SSI Schäfer stands out for the automation of the end points of the 'sorter' in combination with a 'Split-Tray-Sorter'. In addition, these endpoints are managed highly dynamic. They are "drawers" and directly below the system of classification (sorter). Customer boxes are prepared dynamically and in the order appropriate under drawers to then be emptied. Through this arrangement, it is possible to manage many more orders from customers in the endpoints of the system of classification ('sorter'). In unequal are reached 4,000 orders for 54 drawers. The 'sorter-drawer' combination acts as a buffer synchronization between picking and order box.

Two ergonomic picking locations are prepared 3,600 pieces of clothing per hour and job, to being already open origin boxes and prepared garments are placed in the power of the 'sorter'. Picking locations are designed in such way that it is suitable both for the collection of summer and the winter collection, in which the garments are larger. A tape of automatic feed serves as a buffer between the operator of preparation and the 'sorter' and not hampering the work of operators. The continuous transport system is also done by SSI Schäfer. The classification system distributes the goods at dos pilas to 54 intermediate drawers and which distribute clothing to accurately and automatically to boxes of corresponding customers, which are placed automatically. Then half filled boxes are automatically transported to the storage of highly dynamic intermediate buffer of three aisles and 5,400 locations.

The height of the locations in the warehouse built by Fritz Schäfer is adapted to the height of the open client boxes. In the warehouse of integrated, with 6 halls and 90,000 locations trays, logistical software Wamas managed optimally boxes of origin and destination with a total of 3 million pieces of clothing.

For uneven, the most important benefits of the automatic preparation of orders with the 'sorter' are:

- Elimination of downtime of the 'batch' through the separation of the structure of order picking process.

- Minimize the dynamics of boxes of origin the picking locations (a single article is processed once and for all the orders in the location of picking).

- Maximisation of quantity prepared by article in the course of a process of picking.

- Total use of the locations of picking - despite the enormous and existing structures ABC articles - by the creation of groups of articles and automatic disposition in the optimal order.

Using minimal space, SSI Schäfer has succeeded in creating a highly efficient picking and high-performance solution. Thus, Desigual can ensure that all international stores always have garments of any size and color. Therefore, the logistic solution of SSI Schäfer received two important awards in the ICIL Foundation in 2009, as well as the Spanish Logistics Center.

SSI Schäfer optimizes processes in values

Values AG is an independent commercial company with headquarters in Muttenz, Switzerland, which operates throughout Europe. Founded in 1905 under the name Merkur AG and renamed Valora AG in 1996, it has a staff of 6,500 employees and has approximately 1,400 own points of sale in three European countries.

To make the new central warehouse in Egerkingen to logistics in Switzerland, planning and implementation of the new logistics concept was commissioned to SSI Schäfer. Indeed, the original idea was to optimize the old warehouse of Muttenz, but later opted for a new warehouse, better located in Egerkingen (CH) and with a new infrastructure with additional expansion possibilities to allow planning for future growth.

SSI Schäfer was a manual store in an area of storage of approximately 27,000 square meters, with the system of warehouse management Wamas to optimize the flow of goods. SSI Schäfer took charge of the planning and realization of a system of picking 'pick-by-light' semiautomatizado with a system of continuous transport of containers for the area of tobacco.

Valora AG aimed to homogenize the various processes. The first step was the Union of goods and of the press in the same logistical system. In this way were to simplify the processes of consignment of goods, of transport and its implementation planning.

In addition, had to reduce the complexity of the system created over the years by various software solutions and, therefore, increase the stability and availability of the logistics facility as a whole.

The implementation of the project should not affect the level of service values. Had to empty the old store of Muttenz in time by which the two teams of draft SSI Schäfer and values had tight deadlines. The collaboration between the companies was optimal and had a decisive influence on the successful completion of the project.

Picking "pick-by-voice" system eliminates the use of lists or scanners which results in a continuous workflow. Therefore, achieved a significant increase in the quality of picking.

In the area of tobacco, the picking is done through a 'pick-by-light' system.

The new uniformity in work processes creates greater flexibility in the employment of staff, being able to use the same employees in almost every area. The logistics system Wamas offers transparency and, therefore, potential for optimisation of all processes.

The advantages in the logistics of the press are enormous, especially in the trade magazines, where currently plays an essential role. Where necessary a cycle of between 48 and 72 hours time was reduced to just 24 hours.

Almost all of the volume of magazines to Switzerland is made available through the Logistics Centre Egerkingen. Newspapers are delivered in a decentralized way by the publishers to 11 regional warehouses in all Switzerland.