This news article was originally written in Spanish. It has been automatically translated for your convenience. Reasonable efforts have been made to provide an accurate translation, however, no automated translation is perfect nor is it intended to replace a human translator. The original article in Spanish can be viewed at

En Pallmann, el tamaño sí importaIts success is based on grinding solutions tailored to the clients

In Pallmann, size matters

Ibon Linacisoro15/04/2006

Can someone be crazy by crush? Well, each has its specialties and their particular ideas, but the truth is that there is a very well known in the micronising and grinding technology company in the German town of Zweibrücken, about 150 miles southwest of Frankfurt,where grind, grind, grinding, smaller than do something, is the obsession of workers. It is Pallmann, a particular company that knows what to do with a few simple blades and whose specialization has captured the attention of universal plastics to the point that we decided to move there.

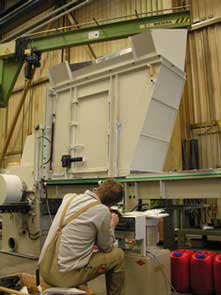

Pallmann performs virtually all industrial processes for the manufacture of their teams.

103 Years ago founded the company which currently leads special crushing sector. A family company specialized in Mills who performs internationally in numerous sectors with more than 1,200 different types of machines for all kinds of materials: soft, cheeses, fragile, tenacious elastic or fibrous. The combination of experience combined with the constant innovation is the secret formula of Harmut Pallmann, seventh generation in charge of this factory in which they work around 400 people, 700 if we add the workers around the world and whose annual turnover is in the 50 million euros20 of which come from the plastics industry.

Harmut Pallmann and Carlos Gómez, Project Manager for Spain, Portugal and Latin America, with a rotor.

But how can survive in the sector of the crushing in a competitive world? Harmut Pallmann explains how the customer who comes to Pallmann seeks a special solution. It has a different from the usual problem and needs someone who knows this so that resolve you the problem. "We not only manufacture the equipment." We the customers specific solutions, of course, always bearing in mind that the processes that we provide are stable, that require little maintenance and spend little energy. We are, to put it in some way, the tailors of the crushing. "And in addition to the tailored suit, we do it quickly and at absolutely competitive prices."

Among the more than 1,000 machines that have been manufactured in this factory, there are also conventional Mills, where Pallmann also comes to compete with the rest of the global competitors. But it is in the special where Pallmann takes its maximum performance, where the domain of the grinding technique brings to the table. Sometimes it's a particularly problematic material, sometimes is the integration of a process of grinding in a production line that is of concern to the client. "Here, says the maximum head and owner of the company - analyze, look for alternatives and come to the right solution for everything that can not solve a standard mill." They are plates of x-ray, Kevlar fibers or surplus of process of extrusion, anything... "We found the solution."

The system Pallmann has devised to offer special solutions without that prices will shoot is simple, but at the same time extremely effective. Account with a technology centre which performs tests for clients, he studies the behaviour of their machines and develops solutions for clients on a smaller scale. If the solution works, and the customer is satisfied is the manufacture of the mill that the client needs. Pallmann engineers not only well known this specialty, they come to the customer to understand what is really needed.

In the grinding of plastics the future points to the automation of food. It is something that customers demand with increasing frequency and, in fact, already it is supplying.

In Pallmann all components of the machine are checked in detail.

It was in 1972 when the current technology center was built. Here is cooked the formula for success. No manufactured in this space, but it discusses everything to the last detail. It is here where the obsession with crush acquires its true meaning and where challenges are taken as such. A customer has a problem and a solution is being sought. Here, with some 130 installed machines, they develop and optimize processes, review teams, tested ideas, it risks and proposed solutions of complete lines. Finally, the truth is that it is the client to decide. And of course, in the case of Pallmann, customers have decided, because it is not easy to remain in positions of leadership in a sector in which, in all, globalization has manifested itself in a presence in the market of machines from around the world.

Grind to third parties

The advantages of the technology centre should be added that, 40 km of its central factory, Pallmann has another factory to serve other companies needing a job at specific moments of crushing. There are processed approximately 20,000 tonnes of material and the great advantage is, understandably, has installed Pallmann machines, so that the company checks the performance and capabilities of their own machines in production environments. Suffers from their teams "in his own flesh", so to speak in some way. Ease of management and the reduction of the maintenance are two of the most common enhancements to the teams, because the attrition in these teams is very relevant.

Another feature of this plant is the expansion of the range of services and solutions to its customers.

Improvements in the change of the blades are also performed, improving the possibility of a quick cleaning and accessibility to the rotor.

Pallmann also has two factories in United States and Brazil, where it is built with the same principles as in the German Confederation. Are supplied from there both machines and complete installations and the concept of providing solutions is present in the same way as in Germany.

To cope with the competition

Competition of Asian machinery, that in other sectors is so obvious, is not an exception in the sector in which acts Pallmann. But its Director-General it is clear: "the steel is equal for all." All you can buy the same steel in the market. But the heat treatment, what we do with the steel, in what become, aspects such as the pitch angle of the blades and their own willingness... here is our added value. It is here where won us our niche in the market, because we know our business than anyone else. We know how blend with minimal effort, such as minimize wear, how to configure the blades in the best possible way. This is the really important. We do our own blades and make our own heat treatment of steel. "In this way, we control the behavior of our teams perfectly".

Pallmann is a robust machine construction specialist.

The problem of copies arriving from certain countries in Europe is no stranger to Pallmann. Asked about this issue, Harmut Pallmann points out: "copying is easy, many people can do that." But it is not easy to copy the philosophy of the 400 professionals who work here. Here we are 'crazy by blend'. We are technology leaders, we have been the first to launch numerous technologies to the market. Long before the recycling is an important topic, we were already in this. "All the knowledge that lies behind this experience and this ambition, you can copy so easily".

On the other hand, the fact of using his business solutions not standards of crushed positions Pallmann in a privileged position because of the difficulty of competing with this concept. "The teams of some Asian countries - supports H. Pallmann - are cheaper because they manufacture very high amounts, but they are always standard and Mills smaller in size than what we are capable of doing".

A 2005 emerging

The location of Pallmann in many sectors and many countries (only 17 percent of sales comes from Germany) placed in a good business situation. Not rely on a single sector allows you to avoid the potential problems of one only. 2005 was a year in promotion for the company and the prospects for 2006 are also good. "Injection sector, perhaps the weakest now in the plastics sector, is not so important for us." "The packaging is and we are getting good responses and, in general, we have very good prospects for 2006 in regards to our plastics business."

Harmut Pallmann explains it clearly: "Is true that in some areas the price of a mill is the decisive purchasing factor." Perhaps here we do not have such force. But for custom-made solutions, where we are the leader, the price is very relative. The installation must be profitable, matters not so much the price of the mill itself, but operating costs. It should take into account the cost over the entire lifecycle of a computer. If we lower the energy consumption by 30 per cent or maintenance by 50 percent, as we can do, we are offering advantages that allow us to be where we are. "Understandably, count on a modern Park of modern manufacturing technology and machinery, it is also very important".

A quick walk

The factory of Zweibrücken is well prepared. The Pallmann have managed, generation after generation, search the way proper make to serve their clients and still absolutely keeping the structure of company family, led by Harmut Pallmann which, by the way, already has an eighth generation when the time comes. The headquarters is clearly divided between the area of manufacturing and technology centre. But also has a training room for workers, representatives and even customers, which is also used to deliver lectures. The technical office is divided by type of product to optimize an adequate flow of information.

Applications for everyone

Pallmann they know of reduced sizes. With more than 45.000 tests crushing in its technology centre, the decisions take its engineers are based on a sound basis. Mills of blades, turbo, disk, batidores Mills, here can do everything and for all types of applications. Its equipment is used for the preparation of mid minerals (gypsum, bentonite, clay, talc, graphite, limestone, marble slates, asphalt, among many others), coal, pigments of colour, pharmaceutical products, salt, chemicals (aluminum sulfate, nitrate, ammonium, magnesium, detergents, soap powder)(, among many others), fatty products, resins and tars, food products (pasta, corn, cacao, starch, alfalfa, rice, among others), fibrous products (shavings of wood, leather, Cork, Reed, and many more) and recycling (electronic waste, copper, aluminium, cable, used tires, scrap of aluminium waste). And, of course, as not, plastics.

The plastics industry is very important for Pallmann. Not in vain to plastics applications represent 40 percent of its sales. Its mills are used for the preparation of polystyrene, acrylic glass, cellulose acetate, resins phenolic, PVC, PE, PA, PUR, PS, PP, Teflon, foam, plastic waste and bales of rubber.

Number of single, double or multiple axis crushers, crushers security, pretrituradores, cams-breakers, desmenuzadores, desfibradores, serrated or smooth roller mills. For soft or semiblandos materials.

In the field of the granulation, provides complete lines, granulators, grinders and mills of blades.

In recycling, the agglomerate is the proper installation to recover materials without merging them and get great value with high density and fluidity granules.

The spraying is a field in which Pallmann also moves with authority.

The range is very broad and would require much space to go into detail, but it cannot fail to highlight the Palltruder, a system for the production of compounds with additives of any kind with different percentages of content.

After the latest edition of the (K) of Düsseldorf, for example, has acquired a growing relevance obtain granules of WPC (Wood Plastic Composite), for which there is the patented technology Palltrusion and Pallwood granule, name recorded by this company.

Also in the area of the micronized of plastics, Pallmann, with compact installation Polygrinder, is reaping numerous successes.

Related Companies or Entities

Meeting y Salones, S.A.U. - Salón Internacional de la Logística