The work in the steel from coils

The steelworks produced the plates of sheet in coil form, it is the only way to manipulate and store steel practical and economical way. Later, before passing through one or more wholesalers, the sheet is cut to format according to the needs of the client. This is a process that facilitates the work of sheet metal products manufacturer but that makes the cost of the raw material. In addition, the manufacturer must have in several different formats according to their production needs, posed a surcharge due to the costs of storage and stock management.

Everyone knows that plates cut format did not always have a perimeter that allows their use: deficiencies in the Court are that we should waste the ends if we want to obtain a metal piece with standards of quality and repeatability.

The solution to these problems brings the work directly from coil. The manufacturer can purchase the sheet in coils of standard width or make the cut of them in a simple and economical line of court in their own units.

The first advantage is that better suited the raw material prices due to less handling of the product can be obtained. But it is not the only one. The coils can limit stocks, since only you must differentiate between various types of materials and thicknesses, never of formats. It should not be forgotten that the price per square meter of soil is increasingly higher in industrial zones and that, in addition, limiting references in the stores is they are saving also within hours of the materials handling and management. The reduction of the handling of packages of sheet metal influences also the decrease in accidents among workers.

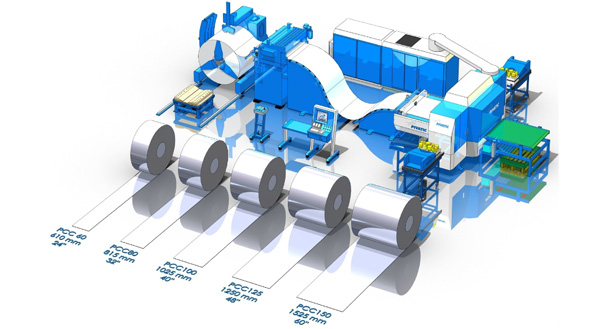

The current flexible manufacturing centres are the solution to work the plate in coils with higher levels of productivity. Pivatic offers a comprehensive response to the needs of manufacturers of sheet metal products in its range of products: furniture Office, ventilation and air conditioning, shelves, panels, lighting, telecommunications, etc. all them are products that can be manufactured with the highest quality and with very high productivity with flexible production of Pivatic centers. It should not be also forgotten that subcontracting firms can benefit also from the advantages of working with coils.

Productivity

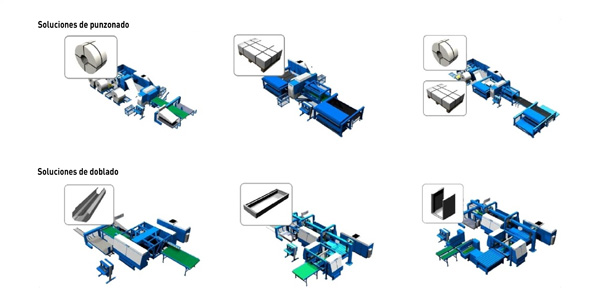

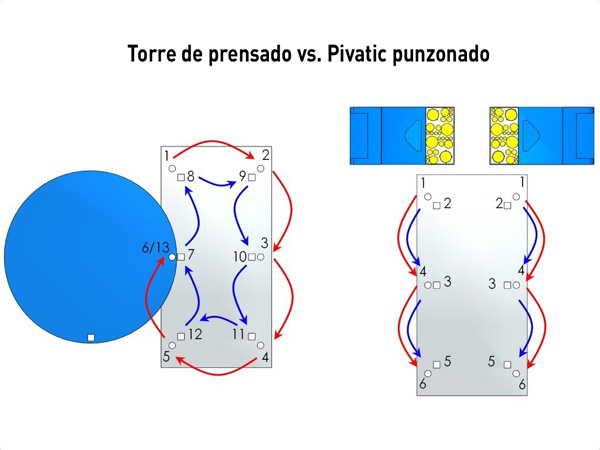

Flexible punching and panelling centers offer higher productivity than machines of format due to several factors.

Firstly, there is no individual processes of loading of sheet format. Either automatically or manually, the conventional machines require a time for the download of the skeleton, the burden of the next sheet and its escuadrado. It is easy to imagine that the coil reduces loading and unloading times to one time for each coil, which generally represent a period of several hours.

In the discharge of parts is also obtained a great advantage over the traditional format machines. Work in coil is that the pieces are drawn from the machine with continuity and their evacuation can be performed automatically or by gravity without stoppages from piece to piece.

The flexibility of installation is that pieces can be paneled after the punching and/or court, preventing the flow of materials and the intermediate steps between different machines: what in the conventional method required two machines with their respective times of manipulationin the Pivatic system, a unique centre of production does all the work automatically. There is also the possibility of making the tool changes automatically, which favors the uninterrupted production of parts.

Economy

We alluded to earlier in this article to the difference in cost between the coil sheet and cut sheet format. To that important savings resulting from the limitation of stocks already añadíamos: space, management and manipulation. But to all this we must add the automation of the process, that significantly reduces labour costs.

The difference is abysmal for loading and manual unloading machines. But even on machines with automatic loading and unloading the differences are striking: the sheet pallets must be loaded with periodicity, escuadrado not always perfect, the hooked in the plate are common, download parts and skeletons slows down the operation, etc but with flexible production centres you can move from the punching to the panelling without the intervention of any operator, reducing not only the cost of labour but earning more parts in less time. In addition, to not be dependent on any operator, Pivabend facilities can produce parts in 24/7 mode, i.e., 24 hours a day, 7 days per week.

Quality

Working with coils provides a continuity in the raw. It is known that the quality of the packages of sheet is not always the same and that factors such as the different hardness or the sense of cutting can produce differences among pieces in the punching, which increase exponentially in the bending process. The repeatability is therefore assured.

But we must also emphasise that the pieces are based on a coil and leave semiacabadas, i.e. punzonadas, cut and folded, in a single process, reducing to the maximum possible imbalances in the passage of a machine to another. This quality eliminates both the possibility of errors and possible damage on the pieces in the process of manipulation of a machine to another. We have ensured, therefore, the same quality of the pieces in all the material loaded on the machine.

Flexibility

The first question that you can perform the reader is is not this type of machinery suitable for large series?

Sadly those happy years in the short series was ran from hundreds of units. The market today, trying to give a quick answer to consumers, not always offers the possibility of making hundreds of equal parts.

The flexibility of the facilities of Pivatic makes it suitable for all kinds of series, both long and short machines. The ease at the turn of the coil makes handling times are extremely short. In addition, the possibility of loading two reels at the same facility.

Simple change of tools reduces the loss of time when manual change is made. But we must not forget that there is the possibility of incorporating into the machine an automatic transmission, which prevents manipulation before the change of product.

On the other hand, the simplicity of the software and the storage capacity of different programs make that we should not worry of possible modifications, you can do without own operator dependent on advanced technician. It is important to note at this point that we can freely program different angles, dimensions, parameterize parts, modify sequences of work, etc.

The range of thicknesses and dimensions that accept the centres of production Pivatic is also very broad. We can work smoothly metals from 0.5 mm thick up to 3 meters and the width of the sheet metal ranges from 300 mm to 1500 mm.