Prevention of occupational hazards in industries that incorporate processes of sheet metal cutting

Prevention must be implemented in all areas and sectors, it is wrong to consider that a company by having a few minimal risks must devote less effort to implement a prevention management system. Prevention has economic costs, which are much lower than the costs of the no-prevención

Prevention of working risks in enterprises management

Occupational risk prevention is integrated into all activities and decisions, both in the technical processes in the Organization and working conditions.

Define, document and disseminate the principles which must base the policy of prevention of occupational risks

2. Prevention in the enterprise organization

| Number of workers | Delegates on prevention | Committee on safety and health (1) | Prevention service | |

| 1-5 | NOT | Alien Empresario/Trabaj./S.P. | ||

| 6-30 | 1 (Of the.) (Staff) | NOT | Alien trabaj./S.P. | |

| 31-49 | 1 | NOT | Alien trabaj./S.P. | |

| 50-100 | 2 | IF | Alien trabaj./S.P. | |

| 101-250 | 3 | IF | Alien trabaj./S.P. | |

| 251-500 | 3 | IF | Trabaj./S.P. own (2) alien S.P. | |

| 501-1000 | 4 | IF | S.P. own / alien S.P. / S.P. manc. | |

| 1001-2000 | 5 | IF | S.P. own / alien S.P. | |

| 2001-3000 | 6 | IF | S.P. own / alien S.P. | |

| 3001-4000 | 7 | IF | S.P. own / alien S.P. | |

| > 4000 | 8 | IF |

|

(2) For companies belonging to annex 1 of the regulation of the prevention services (r. D. 39/97)

The evaluation of occupational hazards is the process to estimate the magnitude of those risks that do not have been avoided, obtaining the necessary information so that the employer is in position to take an appropriate decision on the need to adopt preventive measures and, in this case, on the type of measures to be taken.

4. Preventive planning

4.1 Measures of elimination or reduction of the risk

- Take criteria for the priority of the measures of prevention in the following order: intrinsic safety, collective protection, protective and signage.

4.2 Information, training and consulting workers

- General information about the risks of the company and each post or function and their mediated prevention, as well as measures for emergency action.

- Preventive theoretical and practical training specifically for the job, at the time of recruitment and when there are changes. The training should be continuous. They should be jobs require authorization.

Prior to workers or their representatives on all actions and elements of the preventive system consultation

4.3 Control of hazards

- Inspections and periodic reviews of the facilities, equipment and workplaces preventive /Mantenimiento.

- Observations planned work, especially if it involves risks.

- Instructions of work /Normas of prevention in dangerous tasks.

- Specific risks hygienic, ergonomic and psychosocial control.

- Communication of hazards and suggestions for improvement by any member of the company.

- Monitoring and control of corrective actions.

- Health surveillance.

4.4 Control of changes

- New projects and modifications.

- Procurement of machinery, chemicals and protective equipment.

- Selection of staff.

- Contracting and subcontracting.

- Permits for special work (confined spaces, welding in flammable environments, etc.)

- Appropriation of machines and facilities out of service.

4.5 Control events

- Investigation of accidents / incidents, as well as control of the accident.

- Emergency plan.

- First aid.

5. Audit of the system preventing

Occupational hazards

- Prevention management audits evaluated systematically methods of management, organization and execution of measures for the improvement of working conditions in the company.

- Its general objective is to determine the effectiveness of the methods used, both the suitability of the concrete measures taken.

6 Documentation

- Minimum documentation that is available:

- Evaluation labour risks

- Planning of preventive actions

- Measures and material protection and prevention to take

- Results of the periodic checks of the conditions of work and the activities of workers

- Practice of the controls of the State of health of workers

- Professional relationship of occupational accidents and diseases with incapacity exceeding one day.

Preventive measures

Non-exhaustive list of preventive measures of dangers in the companies that incorporate processes of sheet metal cutting

Risks to the safety of workers:

1 Areas of step

- The pavement of the corridors must: be made of suitable materials,

- Protect any openings and mark,

- Less than 10% in the uneven sloping ramps.

- Keep areas of step: clean, regular and uniform, clearly marked and delimited,

- with enough visibility in the area of vehicles and to allow the passage of pedestrians without any risk,

- free of obstacles,

- lit.

- The width of the doors of the corridors should be correct.

2 Workspaces

- Workspaces field must: be suitable, being regular and uniform, maintain order and cleanliness.

- Have specific areas for storage of materials and tools.

- Protect working platforms with fall of more than 2 m, as well as openings and uneven through secure handrails.

- Adjust the width of the doors of their work premises and place them in sufficient numbers.

- Doors designed to traffic in both directions must: be transparent with indicator signal at the height of the eyes.

- Adapt the doors of emergency number, width and height.

- The dimensions of workplaces should allow workers to perform their work without risks for their health and safety and under acceptable ergonomic conditions.

3 Stairs

- Fixed ladders must: be not slippery materials or they will have non-slip elements, adjust the height and width depending on the type of ladder, have safe handrails when necessary, take fingerprints with uniform and non-slip surfaces.

- The manual steps should: maintain in good condition and use them correctly.

4 Machinery

- Have the CE mark, be installed, used, maintained, repaired and regulated according to the instruction Manual for the supplier.

- Boundaries: between machines, parts of step,...

- Isolation of mobile elements protections systems: fixed, mobile, adjustable, mobile anclavamiento,

- In the case of mobile and adjustable protections they should be associated with mechanisms that control the stop and the start-up of the machine.

- Elements of drive and stop the machines must: be clearly visible and identifiable, placed outside the danger zones and maneuverable only on a voluntary basis.

- Electrical insulation systems

- Thermal insulation systems

- Radiation insulation systems

- Insulation systems noise and vibration

- Systems of insulation materials landslides

- Adaptation of the machine to human abilities and characteristics

- Training and information to operators

- 5. Hand tools

- Have the CE mark

- Hand tools must: be suitable for the work to develop quality, be in a good state of cleaning and maintenance, sorted and stored in appropriate places, be appropriate to the outstanding risks in the working environment, carry out periodic checks.

- Use of personal protection to work with especially dangerous tools.

- Power tools

-Power cables have insulation

safe and without deterioration.

-All connections will be made through standardized pins.

-All hand electric tools during its use must be protected: safety low tension (24 V) switches spreads of high sensitivity (30 mA), installation of grounding, double insulation.

-Periodically check the correct functioning of protections.

-Be they disconnect at the end of its use or pause in the work.

-Do not throw use cable to unplug the tool.

- Workers should be informed and trained in the use of the tools.

6. Manual handling of objects

- The objects must: be clean, not slippery, with adequate grip system, own dimensions and forms that facilitate their manipulation.

- Inform and train the personnel involved in the proper handling of objects.

- Use of personal protective and devices provide, if they were insufficient, other media that can minimize the risks involved in the manipulation of objects.

7. Electrical installations

- To provide facilities of protections appropriate against accidental contact, overvoltages and overloads atmospheric discharges.

- Electric drivers maintain their isolation to the Lake and the joints and connections are made properly

- The maintenance works are carried out by trained personnel and with experience and provides enforceable protection elements.

- Have appropriate safety signs.

- Take mobile and portable electric machinery with adequate tension.

- Use portable electric lamps with grip of insulating material, the protected parties in tension and cage for the protection of the bulb. These lamps must have the proper voltage.

- Installing connections to land of dimensions and materials.

- The general installation available release to land (TT) revised annually and differential switches arranged by sectors

- 8 Pressure vessels

- Use standard color codes to identify and differentiate between the contents of the bottles.

- Protect bottles against extreme temperatures, ice, snow and the Sun's rays.

- Avoid any kind of mechanical aggression which could damage the bottles such as clashes among themselves or against hard surfaces.

- Bottles with non-fixed hood should not grab it. Displacement, bottles, and should be in the closed valve properly Fixed hood.

- Bottles should not drag, slide or roll them in a horizontal position. The safest move them with the help of a truck designed for this purpose and properly tied to the structure of the same. If don't have a truck, the transfer should be rolling the bottle upright on its base or pedestal.

- Do not handle the bottles with hands or greasy gloves.

- Filled or empty bottles valves should be closed by putting them the safety caps.

- The bottles should be stored always in an upright position.

- No bottles to submit any kind of escape should be stored. Flames, but adequate for each gas products are not used to detect leaks.

- For the loading and unloading of bottles it is prohibited to use any element of elevation magnetic type or the use of chains, ropes or slings that are not equipped with elements that allow its lifting with your help.

- Filled and empty bottles will be stored in separate groups.

- Store the bottles in a place where not to stain of oil or fat.

- If a bottle of acetylene accidentally remains in a horizontal position, it should not be vertical, at least 12 hours before it is used. If they cover of ice should be used hot water for disposal prior to manipulate it.

- Handle all the bottles as if they were full.

- In case of using a team of mechanical maintenance for its displacement, the bottles must be placed on a cart, platform or cart fit with valves closed and covered with safety Cap

- Chains or metal wires or even rubber coated cables should not be used to lift and transport the bottles because they can slip

- Where flammable materials such as paint, oil or solvent even if they are inside closets space, must be respected a minimum distance of 6 m

9 Networks and distribution of gas appliances

10 Teams of hoisting

- The maximum load is signed.

- Cables, chains and other accessories of eslingado used must conform to the coefficients of use provided by the manufacturer.

- All accessory grip and lifting into disrepair (deformed, garnished with corrosion, etc.) is immediately replaced and scrapped.

- The machine of devices that maintain the amplitude of movement within the limits laid down is equipped.

- In the event of total or partial failure of the power supply, the grip and stability of the load is guaranteed.

- Media pressure and subject are suitable to avoid an untimely fall of the load.

11. Means of transport

- Stability of the environment and loading systems

- Transport systems indicate the maximum load, have adequate braking system, provide automatic stop devices before electrical failure, acoustic and light signalling devices be available when they interfere with work or visiting areas.

- Use cables and chains features and appropriate dimensions, with coefficients of safety and appropriate and subject to periodic checks roadblocks.

- Adapt maneuver posts giving them protections that allow a perfect visibility of areas of action.

- Positioning the elements of command in correct places and giving them protections against ongoing accidental release.

- Information about the safe use of equipment and training.

- Adjust the speed of the equipment.

12. Fire and explosion hazard

- Have the certificate of fire prevention.

- To provide the local systems to prevent the spread of fire to other areas, as well as suffocation of fire system.

- Correct and easily visible signs of the routes of exit in case of fire.

- Fire-fighting facilities must be maintained and verified on a regular basis. They must be located in a place suitable and properly signposted and without that there are obstacles to their access

- In places where there are flammable or explosive vapour, have adequate suction and ventilation systems.

- No smoking in premises where there is danger of fire.

- Having flammable producer safety data sheets.

13 Risk by the presence of explosives

14. Chemical hazards

- All hazardous products are sufficiently identified and properly marked.

- It has safety data sheets of all hazardous products used.

- Exposed persons know the risks of these substances and are made in the implementation of safe working methods.

- Stored hazardous chemicals by grouping those that have common risks and avoiding the proximity of the incompatible.

- Properly labeled containers store flammable products protected cabinets or in special enclosures.

- The storage area is properly ventilated, whether natural or forced draught.

Risks to the health of workers:

- Extraction in the sources of pollution.

- Initial measurements and, if necessary, regular to control the presence of pollutants.

- Item is the cleaning of jobs periodically premises.

- Is the maintenance of the ventilation facilities

- You are prohibited from eating, drinking or smoking in workplaces.

- Waste should be classified and disposed of according to the legislation on waste.

2 Exposure to carcinogenic agents

3 Exposure to biological agents

4. Industrial ventilation

- Provide adequate ventilation systems.

- Provide for a renewal of air adequate for each local.

- Workers must not be exposed on a frequent or continuous basis to air currents (these limits shall not apply to air currents expressly used to avoid stress in intensive exposure to heat or to currents of air conditioning)(, for which the limit will be 0.25 m/s in the case of sedentary work and 0.35 m/s in other cases).

- Review the status of entrance and air extraction grilles.

- Be systematic in all systems of ventilation adequate maintenance.

- Install extraction system located at the points where there are risks of pollution or harmful or toxic substances are handled. Also, verify the effectiveness of these systems eventually, and that its size, shape and position is adequate.

- Eliminate cross-currents of air.

- Verify the compatibility of the filter with the vapours breathed for the filter range hoods.

5 Air conditioning in the workplace

- Provide adequate systems for mining and processing of air.

- Provide for a proper preventive maintenance programme,

6. Exposure to ionizing radiation

7 Exposure to non-ionizing radiation

- Radiation insulation systems: shielding screens

- Use of EPI's to the welder and Assistant

- Mark the affected area

8 Lighting

- Give each area of work of security of sufficient intensity lighting.

- Avoid glare and shady areas.

- Avoid lighting facilities pose a risk of accident to workers.

Provide for a programme of preventive maintenance of the lighting systems, which immediately replace damaged light points establish a cleaning program, as well as the regular paint.

9. Physical work load

- Facilitate support.

- Adapt work to the person.

- Reducing the burden

- Movements of frequent loads will be carried out with the help of mechanical means.

10 Mental workload

11 Working on video terminals

Preventive measures of the specific risks

- Location

- Isolation, screening, cabinets, curtains,...

- Signalling

- Integrated security of plot them

Ventilation

To combat the risk of fumes and gases harmful to the human body, we can and we must take various measures: a convenient general ventilation and the necessary extraction or smoke drive system

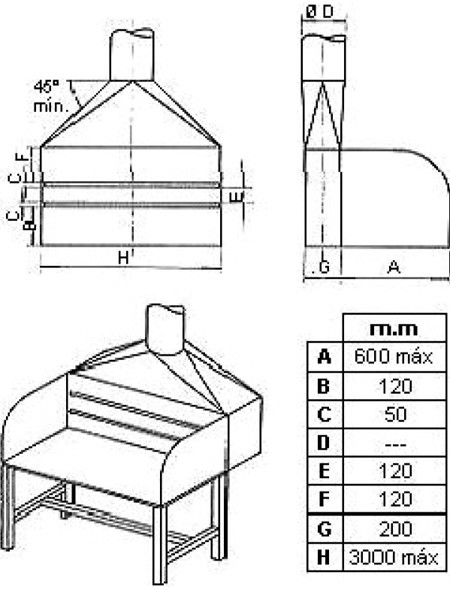

Localized extraction

- Bells of capture should be closer as possible to the focus of generation

- Sufficient flow. The extraction flow will depend on: adaptation of the Bell to the focus of the mode of presence of external flows and pollutant generation

- Periodic preventive maintenance: Bell, flow and cleaning of ducts and filters

- Semimóvil extraction system: due to the work that I know is making the worker be moved within the industry.

- Portable System.

- -Fixed: used in the Workbench where will continuously make the welds.

- Personal protection system: masks.

- System incorporated in the screen, so that gives us both the eye and lung protection.

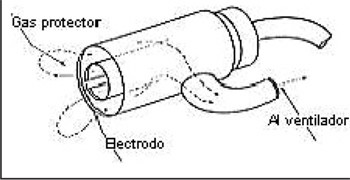

- Another solution would be to use a gun with smoke extraction, the torch has incorporated an extraction system, but does not eliminate all harmful gas for what will be needed to accompany it with other measures.

Preventive measures in work

with cutting fluids:

- Appropriate choice of cutting fluids

- Automation of operations

- Enclosure of machines

- Cleaning jobs

- Personal hygiene

- Localized extraction

- Use of neutral soaps and sunscreens

- Medical control

- Appropriate (EPI's) personal protective equipment

Personal protective equipment

- Leather leggings

- Safety footwear

- Helmet (helmet and mask protection) welder

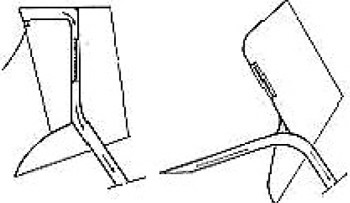

- Manual lift protection screen

- Long-sleeved leather gloves

- Leather sleeves

- Leather apron

- Helmet safety, when the work required.

C. SOURCES OF INFORMATION

- 6 NTP: Radiation in welding. Guide for the selection of eye filter

- 7 NTP: Welding. Hygienic risk prevention

- NTP 153: Guillotine for metal shear

- NTP-261 of the INSHT - risks of the use of lasers.

- 493 NTP 1998 skills and abilities of the controls to change. Change of attitude in the prevention of occupational hazards (II): methods and classification.

- 494 NTP 1998 electric arc welding: safety standards.

- NTP 495 1998 oxyacetylene welding and flame cutting: safety standards