This news article was originally written in Spanish. It has been automatically translated for your convenience. Reasonable efforts have been made to provide an accurate translation, however, no automated translation is perfect nor is it intended to replace a human translator. The original article in Spanish can be viewed at

La resistividad eléctrica como parámetro de control del hormigón y su durabilidadResults of a no destructive essay for the self-supervision of the manufacturer and of the user

The resistividad electrical like parameter of control of the concrete and his durability

Carmen Andrade, Institute of Sciences of the Construction Eduardo Torroja (IETcc – CSIC)23/12/2009

23 December 2009

The EHE-08 supposes an advance on the previous versions in diverse appearances of the quality and durability of the concrete. These more strict requirements and the increase of the possibilities of design of the mix that allow the modern generation of additives, as well as the need to converge to a greater sustainability of the resources, suppose a big responsibility for the manufacturer that sees in the obligation to determine in cool state cual will be the future behaviour of the material. Equally, the user has to be protected in his right to sue a product with the quality that has specified. To answer to this need of the manufacturer and of the user, the ideal is can have of a no destructive essay that allow the self-supervision of the manufacturer, as well as the follow-up of the material by part of the user along his cycle of life.

This non-destructive testing is underway for years in the construction Sciences Institute Eduardo Torroja and at the present time since we have results that allow to say that the measurement of the electrical resistivity of concrete is an essay that assess the following aspects of this:

- The hardening fresh

- The degree of curing

- The resistance to penetration of chloride and carbonation

- The rate of corrosion of the reinforcing

It's a non-destructive testing, so it is very suitable for the self-control of the manufacturer and for the quality of the user control

In other words, the electrical resistivity, ρ, is able to inform the manufacturer and the user of the microstructure of concrete, its porosity and water content. Thereby, you have complete control over the stages that goes through the material. As a matter of fundamental and complementary, has developed a method for the design of the components of the concrete mix to achieve a certain resistivity. Being a non-destructive test that can be repeated many times without disturbing the material, it is very suitable for self-control of the manufacturer and for the quality of the user control. Briefly illustrates the main aspects mentioned.

What is the electrical resistivity?

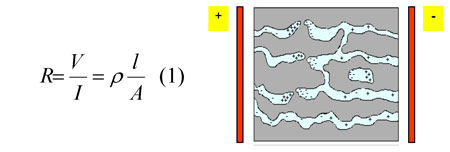

As indicated by Ohm's law, resistivity is a volumetric property of the material and indicates their resistance to the passage of the electric charges:

Figure 1. Porosity can be assessed by the resistance to the movement of electric charges (ions) of the aqueous phase of the pores of the concrete

Where R is the electrical resistance which is measured by applying a voltage V and measuring the passage of current (I). This relationship is equal to the resistivity by geometric factor l/A, i.e. by the l = distance between electrodes and A = cross-sectional area of passage of the current.

The greater is the resistivity minor is the porosity of concrete and higher its mechanical resistance, having more solid phase by volume. In addition, if the concrete is not saturated with water, the resistivity grows, so it is an indicator of the degree of saturation. Therefore, the resistivity is an indicator of the quality of the concrete to indicate its porosity, and is an indicator of the degree of saturation and can be used to control the degree of curing.

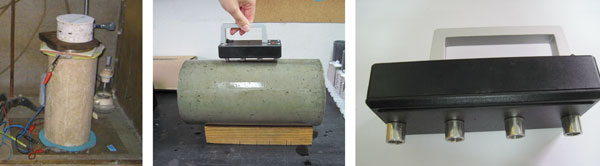

The measurement of resistivity

The extent of the resistivity can be done by placing a few electrodes in the expensive parallel of the cylindrical test tubes (Figure 3) or by using 'method of the 4 tips' (Figure 4). For quick measuring the resistivity in concrete and in situ, the IETcc and Geocisa have developed the portable resistivímetro shown in Figure 4 and 5.

There is also a standard UNE which describes the two methods of measurement: SNP 83988 - durability of the concrete - determination of the resistivity of concrete - part I (direct method) and part II (Wenner method).

Figure 3. Direct method.

Figure 4. The 4 tips method.

Figure 5. Portable Resistivímetro.

The hardening fresh

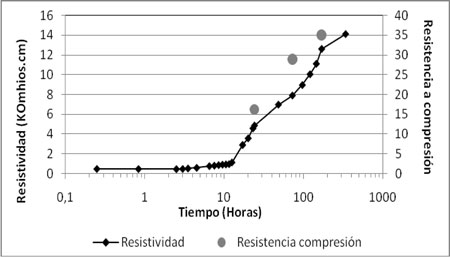

Given that a suspension is obtained by mixing cement with water, the resistivity at the beginning of the mixing is very low, but will hydrating cement and concrete is brewing and tightening, the resistivity increases. Figure 6 shows an example of the curve in resistivity during the first 24 hours. The development of the curve allow identifying the action of additives, as well as other aspects of the setting, which are at the present time of a doctoral thesis (Nuria Rebolledo) in the IETcc.

Figure 6. Development of the electrical resistivity during the setting and hardening.

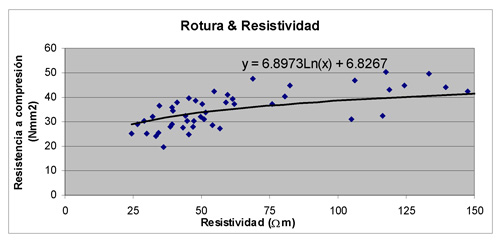

The relationship with the resistance to compression as shown in Figure 6 is also the subject of study and mathematical expressions that bind both parameters, are developing thus enabling the manufacturer to predict the resistance from the first hours.

Figure 7. Relationship between resistance to compression and resistivity for a type of cement.

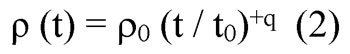

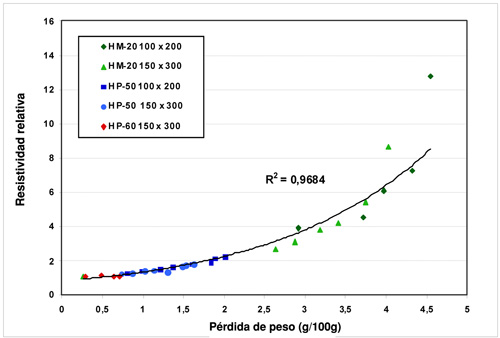

The evolution of resistivity is parallel to the resistance as shown in Figure 7 and therefore the resistivity allows as well as predict the resistance, the "age factor" that it is essential for models of durability that you comment below. Figure 8 shows the inverse of the resistivity in time for a concrete which can calculate the age factor q described in the equation (2).

Figure 8. Variation in the time of the inverse of the resistivity (conductivity).

The degree of curing of concrete

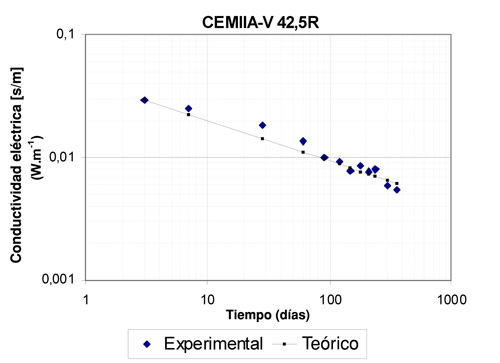

The curing of the concrete is a very important aspect that affects the behavior in the long run while there is a method to quantify it. Resistivity Yes allows it to detect very well the drying surface, and thus the degree of evaporation or saturation of the pores of the concrete. Comparing the resistivity of a well cured concrete with another badly curing is possible to find a percentage of relative saturation of the pores which quantifies the degree of cure (Figure 9). This relationship, obtained by Luis Fernández Luco, in his doctoral dissertation is a very simple method of control in work of curing.

Figure 9. Relative resistivity against weight loss by drying in curing.

Models of durability

The resistance to penetration of chloride and carbonation. The speed of corrosion of the armor.

The current EHE-08 not only shows the proportions of the mixture of concrete that are adequate to resist in every type of environment, but it also provides for an annex 9 which opens the door to the use of models for the prediction of the durability of the hormigo in relation to the corrosion of the armor. These models are still very low precision that they are not calibrated to long term.

The resistivity can also be used in a mathematical expression for the prediction of so much of the period until that develops the corrosion of the armor to quantify the spread of corrosion period. This possibility is based on the inverse relationship between the electrical resistivity and the diffusion of ions. In other words, greater resistivity produces a movement of electric charges (ions of the pores of the concrete) because greater resistivity indicates lower porosity.

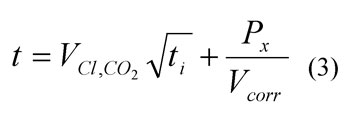

The work has been the subject of the doctoral thesis of Renata D'Andrea. If the total life of the structure is the sum of the period until the armor was corroded (ti) over the period (tp) spread of corrosion up to a certain width of fissure of the coating, it can be said that total lifetime will be: t = ti + tp. And if we believe that the period of initiation is proportional to the square root of the time and the spread is linear with the loss of the armature in diameter it is:

Substituting this expression of the value of the velocity VCl, CO2 income of chloride and carbonation for their equivalent of electrical resistivity expression obtained is:

This expression includes the "reaction Factor" that depends on the type of cement and factors kCl, CO2 which depends on the type of environment. Thus the calculation of the useful life is possible from the value of the resistivity of concrete and a few factors that have fixed values that depend on the environment or the type of cement.

For example, for a coating of 5 centimeters in a concrete placed in the class of manufactured IIIb environment with a cement type II/A, for a lifetime of 100 years and the factors of reaction and age are shown in table 1with the formula (4) calculations result in a necessary value of resistivity of 87.6 Ω·m.

| Type II/A cement |

rCl = 1.8 |

| Kind of exhibition XS2 |

K [cm3year] = 17,000 |

| Lifetime |

t [year] = 100 |

| Thickness of cover |

XCl [cm] = 5 |

| Ageing factor for 10 years |

q = 0.3 |

Table 1. Example of calculation of the necessary electrical resistivity.

I.e., it will be necessary to devise a mix of concrete to a 28-day of cured moist the resistivity. Thus, the durability is possible to calculate with simple concepts through the action of the resistivity of concrete to 28 days in parallel to and it is tested resistance to compression.

With regard to the speed of corrosion of the armor, it is also proportional to the degree of moisture and therefore the resistivity of the concrete in the environment in which: (I)corr = kcorr/r wherecorr k is a constant. The degree of humidity of concrete depends on climate, i.e. the amount of rainfall and temperature. In this connection, it is possible to calculate what would last spread of corrosion period until it reaches a preset the coating crack.

Design of concrete mixture to obtain a certain resistivity

This is what allows to use the concept of the resistivity of a practical by the manufacturer, it is necessary to devise a mix that provides the values required in the same way that makes for a certain mechanical strength.

This aspect has also been studied by Renata D'Andrea in his doctoral thesis. It is possible to relate the resistivity with the composition of the mixture through the laws of Powers (who calculate the porosity of the pulp of cement from the w/c ratio) and Archie (which relates the porosity with the resistivity). Thus, assuming a content of cement per cubic meters of concrete, i.e., a volume of pasta per cubic meter, can be calculated relationship w/c which allows to obtain a given porosity and thus certain resistivity of concrete. To complete the study it is necessary to also apply the "tortuosity factor" that has been calculated for each type of cement.

In Figure 10 are relations were found in a series of concrete studied between calculated and measured electrical resistivity. The methodology that can be followed is:

1. Choose the type of cement and will return cement manufacturer the values of the factor of delay (r) and tortuosity (τ).

Figure 10. Relationship between the value of the resistance, measured at 28 days and estimated from the model based on the law of Archie.

2. It is estimated a relationship w/c, which will be introduced in the calculation of the porosity of the pasta for the equation of Powers, and a content of cement (c), which will be introduced in the calculation of the porosity of concretewhere ε = εp· Γ.

3. Apply the equation based on the law of Archie, ρ = ρ0 · (εp · γ)-Τ, where it checks the values dear to w/c and (c) are ideal for achieving ρ calculated in step 2. In the case of not achieving the target would happen to a complementary step would either choose another type of cement with other values of r and τ to check the validity of w/c and (c), or you can change the values of w/c and (c) to achieve this.

4. Finally, it finds that the value of rap complied the defendant by the designer of the project through the experimental determination of the resistivity in the saturated concrete at 28 days, ρis, from the relation ρapr.

Conclusions

The need to calculate the durability of the concrete has led to seek a trial that was able to quantify all the phases of the process from the manufacture of concrete to its curing and hardening. The electrical resistivity as inverse of the conductividad-difusividad is a property of the concrete which allows their control not destructively and therefore accessible to self-control. The resistivity is an indication of the hardening and mechanical resistance, the degree of saturation of the concrete and therefore the degree of curing and impermeability or resistance to the entry of aggressive substances in concrete. Finally it has a direct with the corrosion rate relationship to indicate the level of humidity in concrete.

ReferencesAlonso, C., Andrade, C., González, J.A. (1988) ' Relation between concrete resistivity and corrosion rate of the reinforcements in carbonated mortar made with several cement types', Cement and Concrete Res. Vol. 18, pp. 687-698.

Andrade, C., Alonso, C., Arteaga, a. & Tanner, p. (2000) ' Methodology based on the electrical resistivity for the calculation of reinforcement service life' 5th Canmet/ACI Int. Conference on Durability of concrete - Supplementary papers volume. Barcelona, Spain, pp. 899-915.

Andrade C., d'Andréa R.., Castle a., Castellote M. ' The use of electrical resistivity as ndt method for specification the durability of reinforced concrete NDTCE'09, Non-Destructive Testing in Civil Engineering', Nantes, France, June 30th - July 3rd, 2009

Baroguel-Bouny, v.; et al., ' Concrete design for a given structure service life. Durability control with respect to reinforcement corrosion and alkali-silica reaction. State-of-the-art and guide for the implementation of to performance-type and predictive approach based upon durability indicators' (in French), Scientific and technical documents-AFGC, July 2004, 252 p.

McCarter, W j., and Garvin, S., (1989) ' Dependence of Electrical Impedance of Cement-Based Materials on their Moisture Condition', j. Phys. D: Appl. Phys., Vol. 22, pp. 1773 6

Monfore, G.E. (1968) ' The electrical resistivity of concrete'. Journal of PCA, pp.35-48.

Page, C.L., Short, N.R. & the Tarras, a. (1981) ' Diffusion of Chloride lons In Hardened Cement Pastes' Cement and Concrete Research. Vol. 1 1, no. 3, pp. 395-406.

Polder, R.; Andrade, C.; Elsener, B.; Vennesland, or.; Gulikers, J.; Weidert, R.; and Raupach, m.; "Test methods for on site measurement of resistivity of concrete'", RILEM TC 154-EMC: ' Electrochemical techniques for measuring metallic corrosion', Materials and Structure, Vol 33 (2000), pp. " 603-611.

Tuutti, k. (1982) ' Corrosion of Steel in Concrete', Swedish Cement and Concrete Research Institute (CBI) no.4-82, Stockholm.

Wang, C. Zhang and W. ' Sun, Fly ash effects. II. The active effect of fly ash, Cement and Concrete Research 34' (2004), pp. 2057-2060

Wenner f., 'A method of Measuring Earth Resistivity'. Bull, National Bureau of Standards, Bull 12 (4) 258, s 478-496; 1915/16.

Whiting, D. 1981, ' "Rapid determination of the chloride permeability of concrete'-Federal Highway Administration - Report FHWA/RD-81/119."

Related Companies or Entities

Consejo Superior de Investigaciones Científicas