Personal safety and environmental protection in the laboratory

The conventional showcases provided with evacuation abroad through were formerly important to the handling of large quantities of goods or products difficult to manipulate. However, these advantages are offset by disadvantages such as:

- The emission of toxic substances into the atmosphere.

- Loss of heated or cooled by teams of conditioning air.

- Continuous need of replacement air.

- Difficult and costly installation.

- The lack of mobility and flexibility in the location of the Cabinet.

To overcome the above disadvantages, it is necessary to consider the use of display cases of aspiration and filtration of gas - without through evacuation and with recirculation of the air - equipped with activated carbon filters, which provide protection at low cost without emitting pollutants into the atmosphere.

The display cases of aspiration and filtration manufactured by and branded Cruma, company with more than 30 years of experience in national and international markets, are based on this technology, ensuring the personal safety and environmental protection in the laboratory.

To better understand the benefits of the showcases of gases without evacuation through we will expose how these showcases leak toxic, foul-smelling and/or polluting vapours during experimental procedures in the laboratory.

Filtration technology

In general, we can affirm that molecules with molecular weight greater than 30 and 60 ° C higher boiling points are candidates for the adsorption on active carbon filters, although there are exceptions and combinations that must particularly be evaluated.

The fundamental principle underlying the filtration of gaseous molecules is the concept of adsorption. The two processes that make up the adsorption are the fisisorción and the quimiosorción.

(Fisisorción) physical adsorption of gas molecules occurs by diffusion (Brownian motion) or adsorption/condensation by Van der Waals forces. Gaseous molecules reach the empty spaces between particles of activated carbon and spread inland from the pores of these. Lured and captured by the forces of Van der Waals molecules penetrate into the pores, collide against the walls and are finally trapped. The number of pores present in the activated carbon is enormous and, consequently, the total surface area that provides for the contact is extremely high. The specific surface is a measure of the surface area per unit mass, expressed in m2/g. There are coals that reach the 2000 m2 g.

The physical process in the adsorption is followed by the chemical adsorption (quimisorción). It consists of a chemical reaction between the gas and active coal whose reaction product has been joined by chemical bond to the active material. The chemical impregnated active coals expands the number of gases that can be removed from the flow of air by this system.

Effectiveness of adsorption and filtration

The temperature of a gas is very important because greater, lesser is the ability of adsorption, particularly for volatile gases.

In addition, temperatures can even lead to a partial desorption in which the filter "returns" to the current gas part of previously adsorbidas molecules. Usually, the temperature should be kept below 40 ° C.

The relative humidity is an important factor that can affect the effectiveness of the filter. The molecules of gases with low boiling points will be worse adsorbed because in its place will be adsorbed water molecules leaving less pore free surface so that the gas molecules can collide and react. In general, the relative humidity must always remain below 60 percent.

Residence time is the time the air needs to cross the filter during which contact with active coal. Or, put another way, it is the time during which the gas molecules can be adsorbed by the pores of coal before leaving it. This time should be as long as possible. To maximize it, the thickness of the filter should be sufficient and the speed of the air should be the minimum possible. This minimum is conditioned by the need to ensure that the facade speed guaranteed containment and aspiration of pollutants.

Normally, the filter, if it has not been properly stored prior to use, loses effectiveness over time as a result of the poisoning due to the presence of gases in the atmosphere as well as to the effect of the humidity.

The speed to which pollutants are evaporated in the Cabinet as well as the concentration of these vapours are two factors that negatively affect the efficiency of the filter.

Follow-up to the filter

- The speed of flow control to ensure that the pre-filter is not colmatado with dust.

- Chemical control of the air expelled by machine to ensure that the primary filter of activated carbon has not achieved the status of "breakthrough" (air that manages to pass through the filter without that polluters are held).

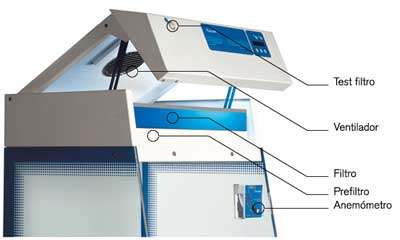

Cruma showcases will be equipped with an anemometer that allows a continuous reading of the speed in front. In addition, headsets have incorporated a sample system that allows the extraction of air filtering for analysis (Photo 2)

The use of high-performance centrifugal fans ensures the maintenance of the flow when the load caused by the pre-filter loss increases.

The adsorption takes place in a bed of activated carbon strip known as "active filtration area". As the filter is being used and loads of molecules, the "active area" will moving upwards until that reaches the top of the bed, moment in which an initial "breakthrough" took place from which the percentage of pollutant gaseous beyond the filter increases. The follow-up of the filter should serve us to detect the "breakthrough" initial period and avoid so achieved the exposure limit values of the pollutants concerned.

Hepa Filters

The acronym Hepa comes from the English "high efficiency particulate air" and they are known as "absolute" filters for very high efficacy of filtration.

They are made of paper of pleated or folded glass microfibre. The technique with which these folds are available is that gives the efficiency of the separation of these filters. The Hepa Filters used by Cruma are class H-14 according to the standard in-ISO-1822, introducing a minimum effectiveness, for particles of 0.3 µm, 99.995%. Category H-14 is more effectively within the Hepa group. The following filter efficiency is the U-15, which already belongs to the category of filters Ulpa (ultraeficiencia), used in special applications.

The third filter element is the pre-filter. Manufactured with synthetic biofibres, class G4 (according to the standard in-1822) allows the retention of atmospheric dust.

Picture 3 shows the image of a head of Cruma cabinet with all the elements making up the ventilation and filtration system.

Types of activated carbon

- Type: adsorption of vapors and organic solvents (ketones, ethers, alcohols, xylene,...).

- Active carbon without impregnation.

- Type BE: inorganic such as HCl, H2SO4, HNO3 acid gases,... and volatile sulfur compounds (H2S, SO3,...). Active carbon with impregnations of metallic compounds and neutralizing salts.

- Type K: specific for steam of NH3 and amines. Activated carbon impregnated with complexes of metallic salts.

- Type F: specific for formaldehyde and derivatives, impregnated with Cu.

- Type ABEK: joint type among the types A, BE & K having the ability to retain molecules belonging to the three groups. Impregnated with neutralizing inorganic salts, salts and metal complexes and Cu.

- Specific types: there is a special for Hg (M-type) filter.

All active coal filters equipping the Cruma showcases are impregnated, developed and tested in accordance with the standard in-141.