Italtech makes clear its intentions

More than 900 visitors of more than 400 different firms, mainly of Italy, Spain, France, Greece, Great Britain, and Germany, as well as USA, Argentina, Brazil and South Africa, among others could see three days the modern facilities of the Italian Italtech and its production capacity in the new plant.

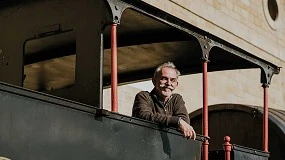

Opened just two years ago, the plant is the first sign of the rebirth of the brand after its purchase by the Pegoraro family to the Fiat group and, with its 8,000 m2 of modern facilities, attests to the bet for the future of this European manufacturer. The new Italtech assumed the challenge of growth, in addition to invest in the development of new models and techniques to adapt to the real needs of the transformer. The consequence of this is its current process of expansion and the increase in the manufacture of machines.

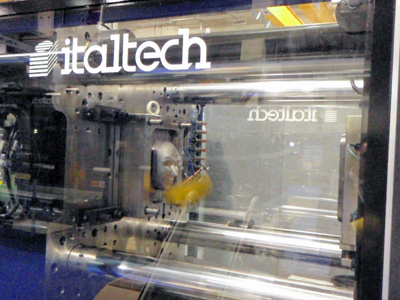

The open days were used to run a new staging of the Newton series, ultrarrápidas injectors of medium tonnage (up to 1,000 tons of closure), presented last March at the Plast in Milan fair. These machines are already manufactured in an improved with respect to the first version. He has been increasing the speed with the use of new materials and download systems hydraulic system of closure type '2 dishes', at the same time that guarantees high performance with energy consumption low, "the lesser of the market in machines for similar applications" according to the manufacturer. Also, the new control by microprocessor Italtech Alpha 7, common to the entire range of machines and based on the operating system Windows, allows to have a graphical interface for communication and programming simple and at the same time as versatile as the final user or production carried outrequire. It is completely modifiable, includes series TV assistance; for troubleshooting, updating of software, production control, quality and even warning of breakdowns, defects or deviations via sms to mobile phones, e-mail or send messages through the computer-generated voice.

Due, partially, this high technology applied to the injectors, was also presented the Saptech of a complete plant of injection computer management system. It is an adaptable system to the new injectors Italtech of immediately and any other type and brand of fuel transfer, even of great antiquity, with a simple application of hardware and software. A communications protocol allows, from a central computer, an exhaustive control of all production and operation of the machines, state maintenance; lots of finished product, storage, etc. Generates statistics as historical machine stops, either by malfunction, failure or human intervention, with records of all parameters, date and time, reason and details, as well as registration of the operator that motivates the unemployment, supervises or modifies settings in the machineproduction or maintenance.

Italtech has 3 lines completely renovated injectors: Impetus, Newton and KL, all of which are manufactured in Europe in its entirety and result of investment in research and applied development. The Italian manufacturer offers cutting-edge technical solutions and infrastructure service in line with expectations and plans for growth of a European manufacturer of injectors who have made the crisis a shock.

KL-renewed series of injectors for large-tonnage (up to 6,000 tons of closing) with the sample of units of 1,000, 1,300, and 1,800 tons (produced in series models), equipped with the advanced hybrid technology of Italtech is also worthy of mention. They combine variable frequency on the engines of the bombs and the electric motor used for injection, resulting in a very low energy consumption. For example, a machine KL 1,800 producing a technical component of the critical requirement for quality automotive, pp, with a weight of 5.270 g and a cycle time of 76 ", consumed only 102,6 kW/h to 249,63 kg/h laminated. Or what is the same, 0,411 W for every gram of material.