The latest technology in lines monoestación

PLAST MILAN 2003

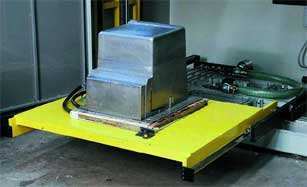

It's a line renovated with respect to the method applied to termoconformar and that stands out of the known systems. In principle, the stages of the process are the usual; the operator loads and alternatively download the sheet and the piece moulded by the front of the machine, the plasticizing and the moulding of the lamina is performed on the same workstation and produces the final product. But there are two heating panels able to forward and back pneumatically from the rear of the machine on this computer. This novelty can reduce implementation times in place of the monoestación and the maintenance and increases the quality and accuracy of the production.

Innovations in mechanics

However, there is the possibility of acting entirely pneumatic way, such as applying for some customers in the automotive sector, with the aim of simplifying compliance with environmental regulations, and thus no hydraulic oil is needed.

The moving parts are made of aluminium, lightening the necessary strength to his movement, but maintaining a high level of structural rigidity. Thus, the average lifespan of mechanical components, drags on. The portamolde plate slides on prismatic guides who, along with torque, it ensures a better stability during the upload and download.

On the other hand, removed the cooling water of the structure of the machine, thanks to a stainless steel protections that isolate heating panels during the phase of waiting.

Manual security gate is replaced by photoelectric barriers in order to improve the visualization of the production process to the operator. The barrier of higher reduction is fixed in the machine and can be manually adjusted via a slider.

The lever for the movement of the bottom plate has been removed and is replaced with a vertical cylinders mounted directly on the plate and the extraction of heavy moulds is simplified through the use of guides of balls, on which slide molds.

Electronics and control

The speedup for the exchange of data between the control and the HC blocks reduces the number of defective parts at sunset in motion machine.

Panel control (touch screen) allows you to enter parameters as the velocity of the plate portamoldes, the required percentage of heating and the use of resistors in ceramic for each unit and its corresponding value as a percentage (100 points of Regulation). This device is very useful for the moulding of parts "difficult" with a greater number of control points.

In addition, there is the possibility of regulating different speeds of rise and fall of the plate portamoldes, thanks to the use of a proportional valve that controls its operation.