This news article was originally written in Spanish. It has been automatically translated for your convenience. Reasonable efforts have been made to provide an accurate translation, however, no automated translation is perfect nor is it intended to replace a human translator. The original article in Spanish can be viewed at

Centrotécnica superó la prueba con éxitoHis represented presented interesting news

Centrotécnica passed the test successfully

For a company like Centrotécnica, with a large number of represented companies, a feria as K is a true test of effort. It requires little more than the gift of presence in several booths at the same time. Move to Düsseldorf to a great team made it possible to the attention of customers in numerous booths where the required information by Spanish professionals. On these pages we see the new features of their represented, with the exception of Italtech, Boy and refrigerators IF, whose information can be seen in the sections of this issue 'What's new in injection' and 'What's new in peripherals', respectively.

Bielloni:

He exhibited four cutting-edge teams which represent an important advance in this field:

• Coextrusion line model STAR STRECH, flat head, useful stretch film 2000 mm, actual speed 450 m/min and production of 1000 Kg/h. head automatic, control of thickness "Beta gange" American manufacturing.

Winder with handling robot, aspas and coils allowing changes less than 60 seconds. System recovery and reinstatement in line of the cuts is forced the shredded dry type.

• Line of coextrusion film bubble to 3 layers for technical film, with automatic cooling fluid segmented ring. Head MULTISPLIT offering optimal homogenization of temperature and residence time bass of the melt.

• Printer flexo to 8 colors type "GEARLESS" model theorem, with change of shirts in machine.

• Cortadora-rebobinadora model B87S, modern version, interface with electric operator/machine, aspas areas for swing and quick change of finished coils.

INSTALLMENT:

Presented in Dusseldorf its wide range of conventional mills of high performance, exceptional quality and finishes; soundproofed and with various accessories to allow adaptation to the most demanding process. Food and drying systems, must be added the precise gravimetric and volumetric dosing systems; dehumidifiers of material and centralized power systems. All these teams were present in Dusseldorf, showing the latest technology in this field, with the quality that accredits this recognized brand.

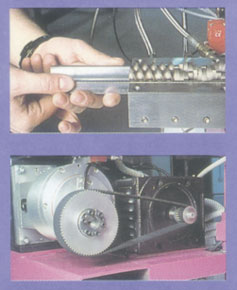

Centrifugal dryers of modular type, allowing to replace the parts subject to wear, the friction of the granule

Gala:

He exhibited the new developments introduced in their systems of granulation under water:

• Systems of court with adjustment of the blades in a precise way, by means of a pneumatic system.

• Centrifugal dryers of modular type, allowing to replace the parts subject to wear, the friction of the granule. Thus, greatly reduces the cost of maintenance and are suitable for the spinning of granules loaded, as for example with 50% glass fibre.

• New models for fast color or material changes. famous models MB for masterbatch expands up to 1,000 kg/h. In this model was incorporated, within the tank the collector of fine.

• Presentation of the new systems of court until production of 40,000 Kg/h.

With the extrusion machines Maris may occur, among others, masterbatch, mixing polimericas, loaded with technical polymers, compounds for cables halogen-free...

Maris:

It was introduced the latest technology in double screw extruders corrotantes, furniture elements. Three extruders models will be:

• TM30HT of laboratory, 900 RPM spindles rotation

• TM40MW turns of spindles 600 rpm

• TM80HT turns of husillos 1300 RPM

With the extrusion machines Maris are puedep roducir the following: masterbatch, polymeric mixtures, loaded with technical polymers, compounds for cables halogen, mixing of rubbers in continuous EPDM-SBR-NBR-NR, polymer for engine oil additives, hot melt based SIS-SBS-EVA, expanded LDPE-Eva, expanded pellet pellets and reticulable base EVA-PE - rubber, pellet additive chemical 100% without polymeric vehicle, adhesive hot melt-based rubber natural, polyolefins with addition of anhydride anhydride, reactive extrusion, etc.

Moditec:

His stan saw a renewed range of the successful crushers to low speed and high torque GOLIATH and BIGGER, capable of recovering flows and parts without dust, without noise, without damaging the structure of materials and with a low installed power. More than 20 existing models, and 50 variants, according to applications; will be adding new features that revolucionarán this sector; as he is the twin-shaft contrarrotante, for blowing containers, unique in the market, developed and patented by Moditec. Other presented equipment will be Mills to install under mold with Hopper of automatic opening and automatic rotor strike-breakers 3 axes with ABS and equipment for crushing of bulky pieces.

TRP:

Was present at the fair with the latest technology in extrusion and complete lines for recovery of plastic materials, most notably systems with court in head under water, centrifugal and compact lines; always with the excellent quality, finish and benefits of PRT. Of particular interest will be the special applications developed for the manufacture of pallets with recycled material, coating of steel for pipe of gas pipes; and innovative lines for recovery online leftovers of film, which allows a significant savings to this type of transformers.

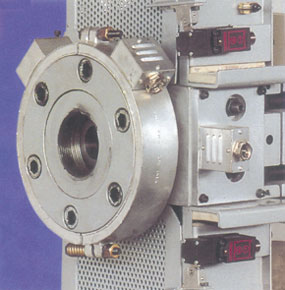

TSA:

It showed as world premiere the new extruder double spindle corrotante EMP45 for the masterbatch industry. The extruder with cylinder of openness to "shell", electric heating, cooling water, 40:1 and furniture husillos length, is robust, compact, providing high productions. Equipped with engine 48 kW., the rotation of spindles is 600 rpm, alternative 60 kW. at 750 RPM It also exhibits the EMP26 model. TSA with this new addition offers its range of laboratory and production based on extrusion machines diameter husillos 21-26-32 and 45 mm

Union:

Showed the calandra special sheet metal PET – PP LFI model; built with tilt of 45 °, motorization of cylinders independent, easy and quick replacement of the cylinder, "cross-axis", air blade system, mechanical cylinder closure suitable for 150 kg/cm. linear pressure. The LFI is without doubt the most versatile calandra of the market. It will be also shown extruder, head and gauge of the striped type, water in contact with the material, for high yields 14 m/min in alveolar iron.

Related Companies or Entities

Centrotécnica - C.T. Servicio, S.A.