Measurement of oxygen dissolved in head offices of power

Chemicals of the water and oxygen dissolved

According to the recommendations of the VGB (Association of Electrical companies and Generadoras thermal sensors in Europe) and the EPRI (Institute of investigation of the electrical power in EE UU), the evaluation of the concentration of oxygen has to realizar beside the analysis of pH and the purity of the water. The high degree of purity of the water makes possible that the concentration of oxygen increase and the pH diminish, improving like this the protection of the pipes of steel. This is due to the oxidation of the protective layer of magnetite to hematita. The hematita presents a lower solubility and a crystalline structure finer, by what seals the porosidad of the magnetite.

Rack Iberfluid Compact in frontal accessible format, including analysers of Or2 LDO, Na, conductivity catiónica, etc.

When it can not achieve a big purity, it is necessary to resort to the increase of pH with low concentrations of oxygen like measure of protection. But so that the concentration of oxygen was very low it is necessary to add agents reductores very powerful (atrapadores of oxygen) with which it is necessary to be very accurate.

In function of the chemical components that apply to the water of the plant, the oxygen has to keep to a level of low concentration (AVT) or inside a specific rank (OT).

The plants that use a treatment oxigenado (OT) are used to to work with water of feeding of boilers with a concentration of oxygen from among 50 and 200 ppb, so that the instruments for measurement of oxygen have to select to favour a prolonged useful life. In these circumstances, the new technology of luminescent oxygen (LDO) satisfies this need with until a year of operation continued without need of maintenance of the sensor.

On the other hand, the head offices of power that opt by a treatment with substances highly volatile (AVT) of the chemicals of the water with cycles of steam to high pressesure usually keep the concentration of OD in the water of feeding of boilers underneath of 5 ppb and the concentration of the condensed underneath of 20 ppb.

Therefore, the measurement instruments of oxygen have to have a high degree of sensitivity. With these suppositions, the sensors of type LDO can use in the majority of the cases, but the electrochemical continue being the sensors of reference when the concentration of oxygen is inferior to 1 ppb.

These are the distinct diets of chemical treatment of the water:

- AVT: Diet of conditioning in which only they add volatile alcaline agents to the water of feeding.

- AVT(R): Conditions reductoras (agent reductor addition) recommended for the units with alloys of copper.

- AVT(Or): Conditions of oxidation (present residual oxygen). Only applicable to units with all the ferrous metallic elements.

- OT: Diet of conditioning where add alcaline agents and oxygen to the water of feeding. Only applicable with all the ferrous metallic elements and water of high purity.

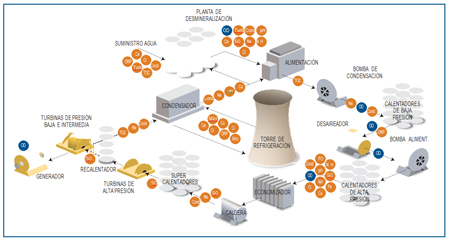

Usually, the continuous analysis of the oxygen dissolved carries out in the water of feeding of boilers, in the exit of the desaireador and in the point of download of the condensed.

Measurement of the oxygen dissolved in the refrigerante of the stator of the generator

The chemical treatment of the water of the refrigerante of the stator is different to the of the main cycle of water because the corrosion by himself alone is not the main cause of the problems that give in the systems of refrigeration of the stator, but the accumulation of deposits in critical zones.

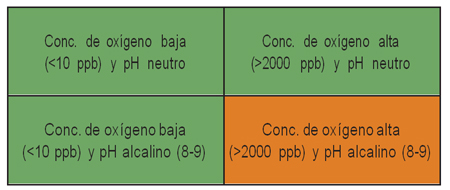

The oxygen dissolved and the pH give place to diets of treatment of the distinct water, with different effects on the generation and release of oxide of copper.

There are four options of treatment of the water of the refrigerante of the stator:

- Concentration of low oxygen and neutral pH. This option of treatment gives in the 50 % of the systems of refrigerante of the stator. A fine layer of oxide cuproso pasivadora protects the tubes of copper.

- Concentration of low oxygen and high pH. If it increases the pH of the water of the stator to 8-9, the answer corrosiva during the transitions of the oxygen reduces drastically.

- Concentration of high oxygen and neutral pH. The aim is to keep at all times a high level of oxygen dissolved in the water of refrigeration. It calculates that the 40 % of the systems of refrigeration of the stator based in water use these parameters. With this diet, forms CuO on the copper that adheres firmly to the surface and creates a layer pasivadora on the metal. This layer is used to to be thicker that the one of CuO that forms in conditions of little oxygen.

- Concentration of high oxygen and high pH. This option does not recommend because it increases the probability of corrosion in the support of the bar.

Typical installation

In the upper image (izda.) It shows a signpost Sentry of conditioning of sample according to ASTM D5540, known like rack ‘primary', to the exit of the cual connects the rack of analysers, such as the signpost of measurement of Or2 dissolved (dcha.). In this, the sample goes in in the centre of the camera of flow through a valve with three roads. This valve allows the interruption of the flow of sample, in addition to the purgado of the road of entrance. All the roads are joined by means of connectors that avoid any risk of entrance of air. Waters down of the camera of flow plants a caudalímetro with regulatory valve. They exist several reasons to use this configuration:

- If the sample of water contains a high concentration of other gases dissolved as, for example, hydrogen (H2), in the case of the water of refrigeration of the reagents of water presurizada (PWR), keeps the pressesure and avoids the desgasificación before realizar the measurement.

- The another reason is that like this it deletes the risk of pollution of air that can generate by the aging of the caudalímetro, specifically of the board of the regulatory valve.

The sensor has to mount in vertical on the valve of entrance and the camera of flow, such as it shows in the image. With this distribution, the bubbles of gas that go in in the camera happen quickly by the sensor until the port of exit.

If it loans special attention to the design of the system of sampling, can avoid the problems of sampling more frequent.

One of the problems of sampling more common are the discrepancies between the analyser in continuous and the portable device. Usually this problem generates by an escape in the tube of the sample that “supplies” a constant quantity of oxygen to the other tubes. The typical reaction is a reduction of the reading of oxygen when it increases the discharge of the sample.

Calibration and validation of the devices of oxygen in continuous

The current portable devices like the analyser of oxygen Orbisphere 3100 can serve of tool of calibration or validation in continuous. First it is necessary to calibrate the portable device according to a pattern trazable in the laboratory and afterwards can use like portable reference in all the plant. Thanks to that the analysers in continuous have functions of direct calibration, this process will not carry him more than some seconds with the portable unit connected to the same location in that they took the samples. In this case, the trazabilidad and the bond to the external official patterns remains totally cover.

The technology LDO for the measurement of the oxygen dissolved offers the advantage of the stability on a long-term basis, even when the device of measurement finds in way of wait. Although the device do not use during weeks or months, the properties metrológicas of the reference of work do not see altered.

On the other hand, the analyser of portable oxygen Orbisphere 3655, with electrochemical sensor, is the instrument of absolute reference for the inferior levels to 5 ppb, with a residual signal of the minimum sensor of 0,1 ppb.

The solution of Hach Lange: the sensor Orbisphere K1100

The traditional electrochemical sensors present a level of derive important in only some months, by what require tasks of periodic calibration and quite a lot of hand of work. Because of his luminescent technology, the sensor Orbisphere K1100 is designed so that it derives it was minimum, what turns it into the most stable sensor and with the greater interval of calibration of the sector.

As it does not be necessary to substitute membranes, does not be necessary to replace the electrolytic solution neither manipulate dangerous chemicals, can say that the sensor K1100 does not need practically maintenance, so alone it is necessary to devote him a pair of minutes to the year.

The sensor K1100 is compatible with the cameras of flow of 28 mm Orbisphere that used before with the electrochemical sensors, so that it does not be necessary to resort to changes of engineering to solder, add neither check new connections. The perfect installation.

With the technology LDO does not be necessary to expect to that stabilise the unit, an additional advantage for the plants to full performance that demand time of fast answer in all the equipment.

The frequency of measurement can configure until arriving to periods of an insuperable length in which it is not necessary to repeat the calibration.

References

[1] Dooley, R. B. Power Plant Chemicals 2002, 4(6), 320.

[2] David G. Daniels, Forgotten water: Stator cooling water chemicals, M&M Engineering, Power, Dec 15, 2007.

[3] Dunand, F. Et al.; LDO Sensor to monitor power plant water and team cycles – PPChem 2006, 8(10).

[4] Optische Sauerstoffmessung in Kraftwerken, VGB Powertech, p119-124, 9, 2012.