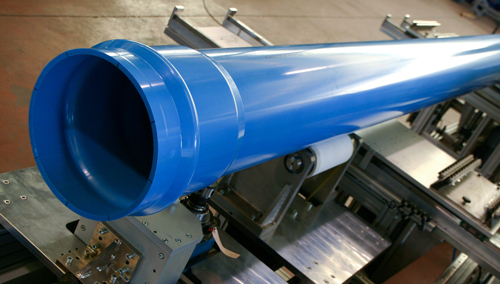

TOM: the new generation of pipes of PVC oriented (PVC-Or)

18 June 2012

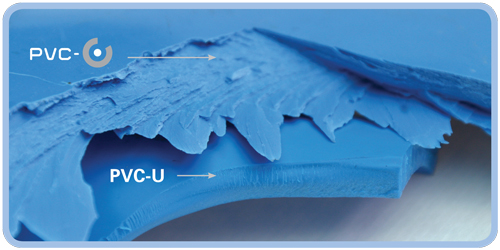

This greater utilisation is due to the exceptional mechanical properties and to the advantages of installation that offer said pipes of PVC-Or with regard to channelling manufactured with other existent materials in the market. This improvement of properties, greater resistance to the impact and hydraulics capacity between others, has to to the process of molecular orientation that takes place during his manufacture that does that the molecules of the polymer order and give like result his characteristic structure laminar.

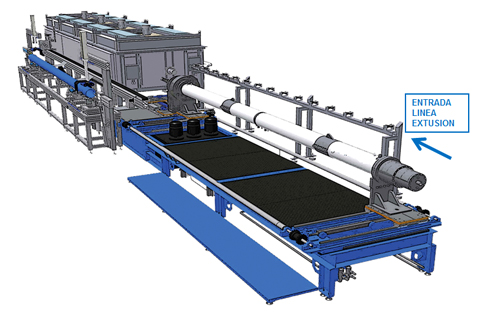

The innovative system of manufacture of

Process of manufacture

Until the moment of the apparition in the market of the innovative technology developed by Molecor, the processes of manufacture of PVC-Or presented difficulties and, in some cases, impossibility to manufacture pipes of big diameters and high pressesures. This new technology allows to manufacture pipes of nominal diameters of 500 and 630 millimetres of until 25 atmospheres of pressesure, converting like this in the first world-wide manufacturer in achieving it. The technological improvement that presents this exclusive system of manufacture redunda in an improvement of the quality of the pipe manufactured, by what “TOM is the new generation of pipe of PVC-Or”.

The pipes of PVC oriented (PVC-Or) manufacture by means of a process of conventional and back extrusion orientation molecular. The molecular orientation is a physical process that modifies the molecular structure of the PVC conventional, happening of an amorphous structure to another laminar that improves of significant form the mechanical properties of the product, at the same time that keeps intact his chemical properties.

Procedures of manufacture for this type of pipes

Process in batch or by batches

This process be produces in two stages. In the first place, it realises the conventional extrusion of a basic pipe or proforma, designed dimensionalmente of agreement to the specifications demanded in the final product. In the second stage, the proforma initial, of manual form and tube to tube, is entered in a mould, and under some determinate conditions of pressesure and temperature, is expanded against said mould, producing in this moment the molecular orientation.

Process in line or in continuous

In this process, the extrusion and the molecular orientation take place of consecutive form on the own line of extrusion, so that the basic tube extruido, also of conventional form, is expanded mecánicamente producing like this the molecular orientation of the pipe of continuous form.

In both cases, the already oriented tube is cooled and cut according to the length wished in the final tube, for afterwards happen to another back stage, where is again subjected to temperature and pressesure, and like this can realise the conformed of the embocadura or glass.

Process Molecor

In this system of manufacture combine the two previous procedures, aunando the advantages that offer each one of them and deleting the disadvantages of the same. Of equal way that in the system in batch, manufactures a basic tube, that is expanded inside a mould to obtain the tube oriented, but the process is automatic and realises the production in continuous

The big difference, finds in the embocadura integrated cheese cheese of the pipe TOM, since it is conformed in the same process of orientation that the rest of the tube. Of this form, can ensure that the glass is oriented to 100% and, therefore, keeps intact all the improvements of properties that have produced thanks to the molecular orientation.

The process also offers other advantages, so much industrial as of quality of product, between which fits to stand out:

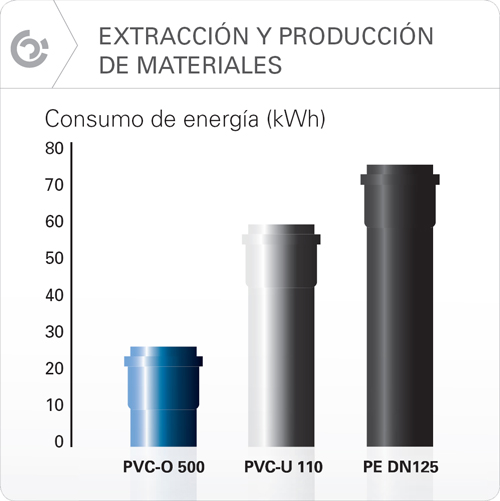

- Optimisation of resources in raw materials. The molecular orientation, at the same time that produces an increase of the mechanical properties, does that it diminish the thickness of the wall. This redunda in a lower consumption of raw materials, that translates in saving of power during the extraction equipment equipment of the same and also during the production of the material.

- Big energetic efficiency. The process requires a lot of less power that the necessary for the production of drivings of other materials and even that other processes of manufacture of tubes of PVC-Or.

- Automation. It reduces the hand of necessary work during the manufacture and ensures the maximum quality of the product, since it deletes , to a large extent, it possibility of the human error.

- High productivity that does can give a fast answer to the needs of supply of the customer.

Which are the advantages that offers the PVC-Or?

The pipes of PVC-Or offer interesting advantages with regard to pipes of materials like ductile smelting, polietileno (PE) or polyester reinforced with fibre of glass (PRFV). These advantages are applicable so much to the quality of the product and to his mechanical properties, as to the greater performance of installation that offer.

With regard to the installation, the greater performance of placing of tubes and the lower cost in machinery and hand of work do that it can tackle the work in a time and an a lot lower cost that if it was executed with traditional materials.

The process of molecular orientation, in addition to improving of important form the mechanical properties of the tube, produces a decrease of the thickness of the wall of the same. Of this form, the pipes have a lower weight and this does that they can be manipulated and installed more easily and of manual form until diameter DN250mm. Besides, the effective design of the glass realised by Molecor, does that the board of estanqueidad remain perfectly installed and that the connection between the tubes realise of form faster.

On the other hand, also is necessary to stand out, that the tube of PVC-Or is very resistant to the impact by hits and to the propagation of cracks, with what minimise of form very significant the breaks during his manipulation and installation in work. This resistance is especially remarkable to low temperatures, where other materials are very fragile.

Regarding the product, the advantages that offers the material owe by a part to his chemical nature and by another to the improvement of properties that produce during his manufacture thanks to the molecular orientation.

The PVC is a chemically inert material in front of the present products in the nature, so that it does not produce corrosion during his long useful life, by what is not necessary the utilisation of protective coatings, as it occurs in the pipes of ductile smelting. Like this, it does not be necessary to concern especially by the quality of the floor where go to go buried the pipes, neither by the quality of the water that circulates by his interior, by what are perfectly valid for the transport of water so much of human consumption like residual. Like this, it ensures that never they go to produce points of corrosion that can alter the quality of the water. Of equal way, is checked that it keeps inalterada the quality of the water that circulates by his interior, since they do not produce migrations of the material.

On the other hand, it is necessary to take into account, that the reduction of the thickness of the wall of the tube does that it increase of considerable form the hydraulics capacity of the driving, that varies between 15% and 40% depending of the material and the diameter with that compare . Also it gives the fact that the losses of load produced are a lot lower, since inner surface of the tube is extremely smooth and, therefore, can realise the transport to greater speed, with what also increases the capacity of the network and minimises the consumption of power in the pumping and the quantity of broadcasts of CO2 associated, with what the pipes TOM offer lower environingingmental impact and have a better contribution in the correct sustainable development of the planet.

The pipes TOM offer lower environingingmental impact.

Another advantage to stand out, especially when comparing with the ductile smelting, is the best behaviour that has the PVC-Or in front of the hit of ariete, that arrive to be until 3 inferior times, with what the hygiene of all the elements of the network increases of considerable form in the enclosures and openings of valves.