Icomatex, S.A. - Stenter frames

Icomatex IC-10 y IC-8

Rame Flat: with a centrador automatic with three oscillating cylinders

The rame flat model IC-10 and IC-8 of Icomatex has the entrance of the fabric composed of two bars tensoras regulables with cylinder of passage and two cylinders ensanchadores in stainless steel for desorillar the orillos, delete crease them and give the width to the fabric. It has of a centrador automatic with three oscillating cylinders by means of a pistón pneumatics, that by means of the reading of the position of the orillo by a photoelectric cell centre the fabric in the machine.

The enderezador of plot IC-End has two cylinders arched that delete the deformations curves and three straight cylinders joined up inside a frame that correct the diagonal deformations. The two groups are accionados independently by means of servomotors.

Optionally they can install some photoelectric cells of reading of the plot for the automatic control.

Has a supercharging formed essentially by an upper cylinder and another inferior motorised, that allow to deliver the fabric with the degree of feeding wished regarding the speed of the chain transportadora of the same. Two wheels recubiertas of rubber have the mission to demand the orillos of the fabric until the point of fixation on the chain. To give the degree of necessary feeding (between +60% and - 60%) acts on a group variator that increases or retarda, as it suit, the speed of all the group with regard to the chain.

Feeding of the fabric: automatic introduction of big sensitivity, ERHARDT + LEIMER prepared for big speeds, that approaches or separates to impulses of two motors (one to each side of the guides of entrance), allowing a suitable fixation of the orillos in the needles or pinzas. Possibility to correct the distance of the orillos through the group And+L.

Device clavador, by means of double game of circular brushes and wheels of rubber of variable and independent speed to right and left with controls for his adjust. Both games are abatibles to situate them off duty.

A second game of brushes ensures the nailed of the orillos on the needles.

A game of photoelectric cells of hygiene of nailed, stop the chain in case of a desclavado of the fabric, doing it very useful when an alone operario works with the machine in the exit.

Of way very simple is possible to control the machine from the place of work, thanks to the frontal design of the signpost of controls.

The main controls find also to the exit to control the exit of the fabric.

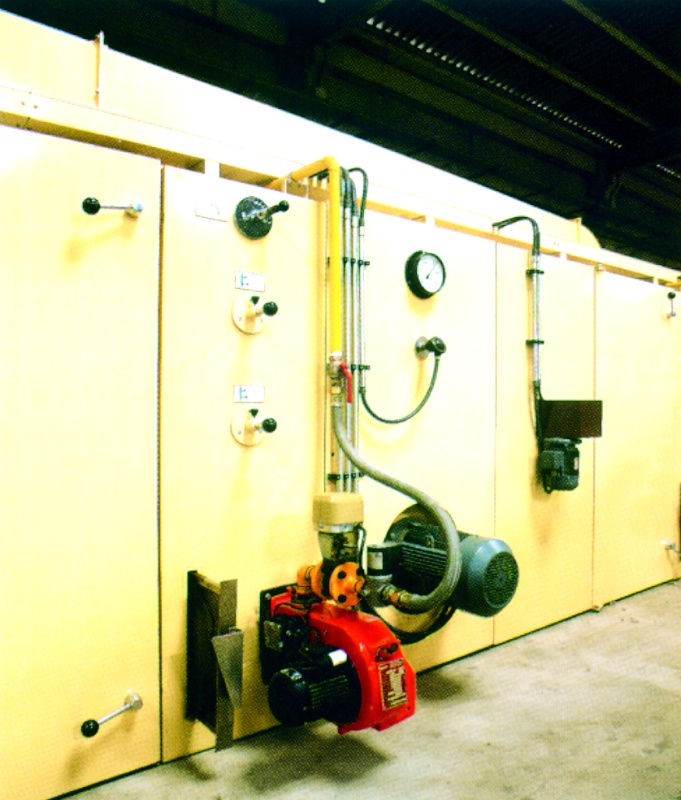

The camera is aerotérmica with circuit of air in recirculation regulable and nozzles soplantes upper and inferior with system of right heating-left to avoid to the maximum the differences of temperature to the wide of the fabric.

Each field is of 3 metres and divides to his time in two sections of 1,5 metres each one for a total control of the air and the independent temperature. The basic configuration of each field of the machine includes two burners of gas or radiadores, two controllers of temperature and two centrifuges fans.

Easy access to the camera for his cleaning as well as for the cleaning of the interior of the nozzles in necessary case. The mouths of entrance and exit of the fabric have a system of closing that adjusts automatically to the width of the guides to avoid losses caloríficas.

The enderezador of plot IC-End has two cylinders arched that delete the deformations curves and three straight cylinders joined up inside a frame that correct the diagonal deformations. The two groups are accionados independently by means of servomotors.

Optionally they can install some photoelectric cells of reading of the plot for the automatic control.

Has a supercharging formed essentially by an upper cylinder and another inferior motorised, that allow to deliver the fabric with the degree of feeding wished regarding the speed of the chain transportadora of the same. Two wheels recubiertas of rubber have the mission to demand the orillos of the fabric until the point of fixation on the chain. To give the degree of necessary feeding (between +60% and - 60%) acts on a group variator that increases or retarda, as it suit, the speed of all the group with regard to the chain.

Feeding of the fabric: automatic introduction of big sensitivity, ERHARDT + LEIMER prepared for big speeds, that approaches or separates to impulses of two motors (one to each side of the guides of entrance), allowing a suitable fixation of the orillos in the needles or pinzas. Possibility to correct the distance of the orillos through the group And+L.

Device clavador, by means of double game of circular brushes and wheels of rubber of variable and independent speed to right and left with controls for his adjust. Both games are abatibles to situate them off duty.

A second game of brushes ensures the nailed of the orillos on the needles.

A game of photoelectric cells of hygiene of nailed, stop the chain in case of a desclavado of the fabric, doing it very useful when an alone operario works with the machine in the exit.

Of way very simple is possible to control the machine from the place of work, thanks to the frontal design of the signpost of controls.

The main controls find also to the exit to control the exit of the fabric.

The camera is aerotérmica with circuit of air in recirculation regulable and nozzles soplantes upper and inferior with system of right heating-left to avoid to the maximum the differences of temperature to the wide of the fabric.

Each field is of 3 metres and divides to his time in two sections of 1,5 metres each one for a total control of the air and the independent temperature. The basic configuration of each field of the machine includes two burners of gas or radiadores, two controllers of temperature and two centrifuges fans.

Easy access to the camera for his cleaning as well as for the cleaning of the interior of the nozzles in necessary case. The mouths of entrance and exit of the fabric have a system of closing that adjusts automatically to the width of the guides to avoid losses caloríficas.