Demag commitment to accuracy, efficiency and economy

The new series Titan of injectors large, with closure of two dishes, presents, according to the manufacturer, the greater distance between columns of its features and great flexibility for installing molds in great volume. It was marketed from this past summer and it will end up including six models, among the 1,100 and 1,400 tonnes of clamping force. In the K may be a Titan 1100 / 1570-11500 (1,100 t of clamping force, 1,570 mm distance between columns and 11,500 injection unit) with spindle powered electrically, which will manufacture a cover from PP reinforced long-fiber at a line equipped with a Kuka robot.

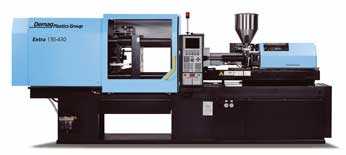

Since its launch in 1999, the S Exis of high performance with plasticizing and electrical movements of mold and injection of high-speed hydraulic, has received a good response from the sector. At the fair you can see two models: a-Exis S 550/1020-7000 manufactured typical pieces of packaging in rapid cycles and a-Exis S 150/500-610 shaping a 500 ml with Cap container using labelling within technology within a 1 + 1 mould cavities of the Swiss Glaroform.

On the other hand, the totally electric fuel transfer IntElect will show how knows to inject precision parts. An IntElect 50/330-4 equipped with a cast of 32 cavities of the Swiss Stamm will be tips of ballpoint pens. Another electric machine, the 150/520-410 IntElect shows during the fair the production of a piece for PE metered with a mold of the German Friedrich Sanner. This machine, suitable for conditions of cleanroom according ISO class 7 in its standard version, is covered by a white room in the fair coverage.

Among the improvements you can speak automatic identifier of the spindle, a function for easier expulsion for the operator and a system of measurement of the career of the injection unit. At the fair there will be two models of this machine.

In the field of injection multicomponent you can see a Multi machine that covers all the possibilities of multicomponent injection. Each of the nine sizes of the Multi, from 560 to 420 t offers the maximum possible light between columns. From 500 to 1,300 t of clamping force range offered includes multi-component machines tailored to the client.